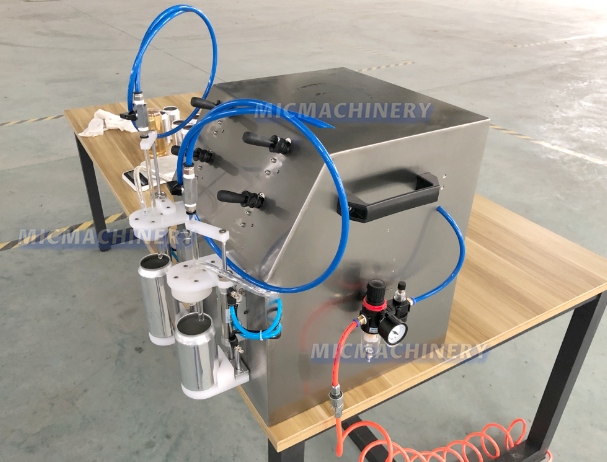

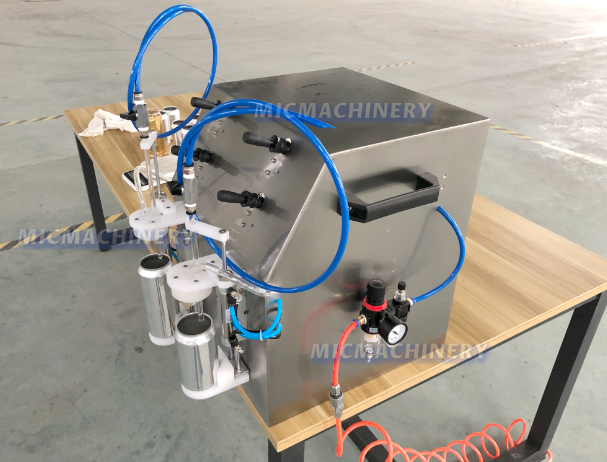

MIC Manual Carbonated Beverage Filling Machine (8CPM)

Machine Is Suitable For

The MIC Manual Carbonated Beverage Filling Machine is ideal for small-scale production lines and craft beverage producers who need a reliable solution for filling carbonated beverages. This machine is suitable for filling various types of carbonated drinks, such as sodas, sparkling water, beer, and other fizzy beverages. It offers excellent versatility and is a preferred choice for businesses with low to medium production volumes. Its compact design makes it suitable for both small factories and artisanal producers looking for an efficient and cost-effective solution.

This carbonated beverage filling machine is also suitable for facilities that require frequent product changeovers, as it can easily adapt to different bottle sizes and carbonation levels. It is a perfect fit for businesses that prioritize flexibility and quality, ensuring that carbonated drinks are filled with precision and care.

|

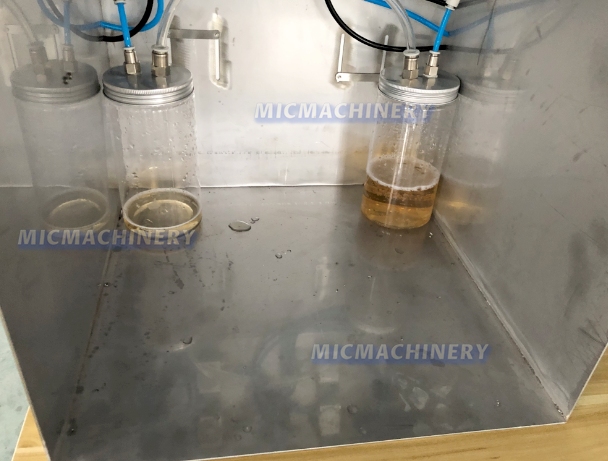

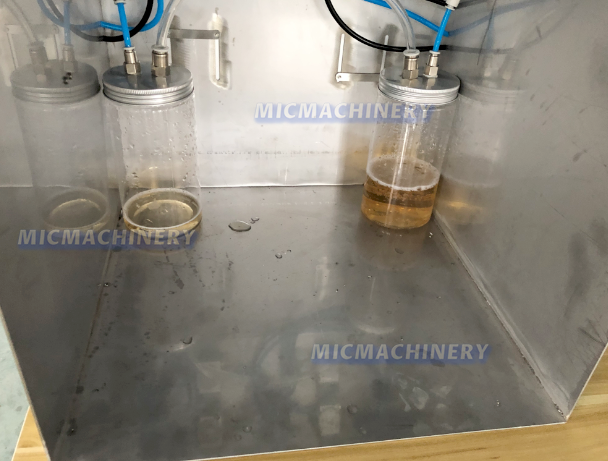

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can.

|

|

Control Button |

|

|

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Machine Features

1、Manual Operation

Unlike fully automated models, the MIC Manual Carbonated Beverage Filling Machine operates with manual controls, providing operators with direct oversight and greater control over the filling process. This manual operation is beneficial for businesses that require more hands-on management or those who are just starting with smaller batches.

2、Precision Filling

This carbonated beverage filling machine is designed with a highly accurate filling system that ensures each bottle is filled to the correct level, reducing waste and improving product consistency. It is particularly suitable for high-carbonation beverages, which require careful handling to maintain carbonation levels during the filling process.

3、Durable and Reliable

Built with high-quality materials, the machine is durable and capable of withstanding the pressures of carbonated beverage production. The beverage packaging equipment is designed for long-term use, providing reliable service even under the demands of continuous operation.

4、Easy Adjustment

The rotary beverage filler mechanism allows for quick and easy adjustments to accommodate various bottle sizes and shapes. This makes it ideal for businesses that produce a variety of product sizes without needing extensive machine modifications.

5、Simple Maintenance

Maintenance is straightforward, with easily accessible parts for cleaning and servicing. The machine is designed to minimize downtime and maintain optimal performance with minimal intervention, allowing for smooth and consistent operation.

6、Compact and Space-Saving

The machine's compact design means it doesn't take up much space, making it ideal for smaller production environments where floor space is limited. Despite its small footprint, it maintains a high level of efficiency and performance.

7、Cost-Effective Solution

The manual nature of the machine makes it a more budget-friendly option compared to fully automated systems, which is ideal for smaller businesses or startups. It offers an affordable solution without compromising on the quality or consistency of the filling process.

Machine Introduction

The MIC Manual Carbonated Beverage Filling Machine is an essential piece of beverage packaging equipment designed specifically for filling carbonated drinks. Its manual operation offers a unique balance of control and efficiency, ensuring that beverage producers can meet the demands of small to medium-scale production with ease.

This rotary beverage filler is built with a focus on flexibility and reliability, offering consistent performance in a variety of production environments. It features precision filling technology that ensures each bottle is filled accurately while maintaining the carbonation levels of the beverage. The machine is built with quality components and is easy to maintain, making it a long-term investment for businesses in the beverage industry.

Designed for businesses that want to deliver high-quality carbonated drinks, the MIC Manual Carbonated Beverage Filling Machine guarantees an efficient filling process with minimal waste and maximum consistency. Whether you're filling glass bottles, plastic bottles, or other containers, this machine delivers exceptional results while helping to optimize production efficiency.

| Filling Heads | 2 Pieces |

| Production Capacity |

8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand |

| Buttons | Schneider (France) |

| Touch screen | Siemens (Optional) |

| AC Contactor | Schneider (France) |

| PLC | Mitsubishi (Japan) / Siemens (Optional) |

| Frequency changer | Schneider (France) |

| Air cylinder | AirTAC (China) / FESTO (Optional) |

| Solenoid valve | AirTAC (China) / FESTO (Optional) |

| Relay | Autonics (Korea) / Omron (Optional) |

| Proximity switch | Autonics / Omron (Optional) |