MIC 12-1 Beverage Packaging Machine (1000-2000CPH)

Introduction to Jiangsu Mic Machinery

Jiangsu Mic Machinery is a trusted name in the manufacturing and supply of high-quality beverage packaging equipment. With years of experience and a deep commitment to innovation, we provide cutting-edge solutions tailored to meet the specific needs of the beverage industry. Our beverage packaging machine and carbonated beverage filling machine are designed for efficient, high-performance filling and packaging, ensuring top-notch quality and consistency for your production line.

|

|

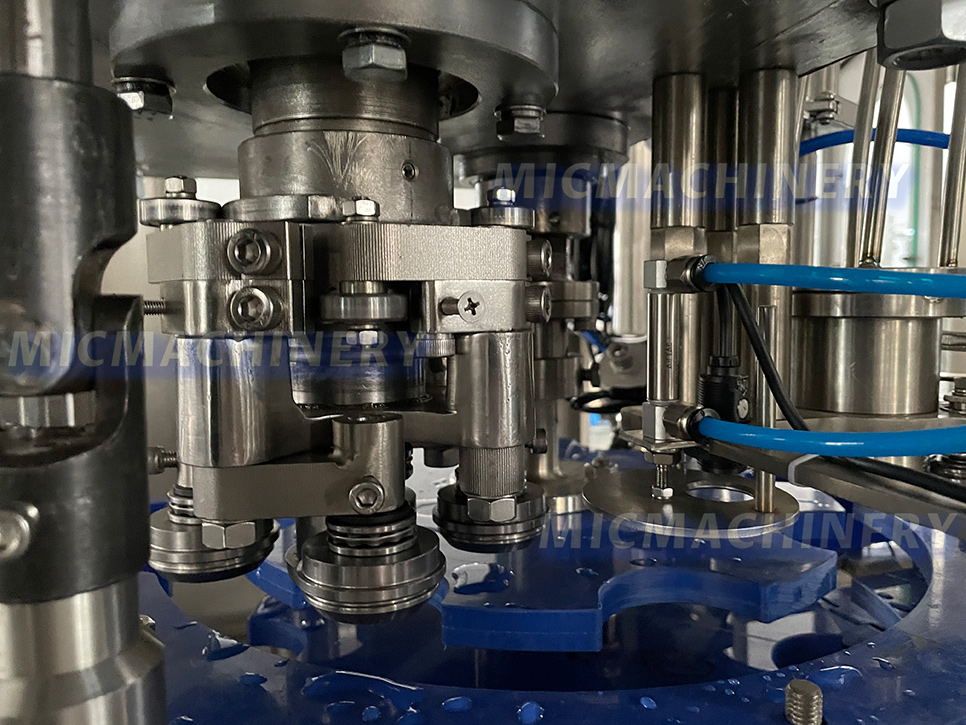

Aluminum can sealing system The aluminum can sealing system ensures airtight, secure seals for beverage and food cans. Designed for precision and reliability, it enhances product freshness and prevents leaks during storage and transport. |

|

Gravity liquid filling system The gravity liquid filling system offers a reliable, efficient solution for accurately filling beverages and liquids. Ideal for various industries, it ensures smooth operation, precision, and minimal product wastage.

|

|

|

|

Liquid nitrogen dispenser The liquid nitrogen dispenser provides precise nitrogen dosing for food and beverage packaging. It enhances product shelf life, prevents oxidation, and ensures reliable, efficient packaging operations. |

Working Principle of the Beverage Filling Machine

The MIC 12-1 beverage packaging machine uses an advanced filling system to ensure that every bottle is filled accurately and efficiently. This carbonated beverage filling machine operates using a rotary filling mechanism, where bottles are automatically loaded and positioned on a turntable. The machine fills the bottles with the designated beverage under controlled pressure and temperature, which is especially crucial for maintaining the quality of carbonated beverages. The process is tightly controlled by a computerized system, ensuring precise and consistent filling while minimizing product loss.

Function of the Beverage Filling Machine

The primary function of the MIC 12-1 beverage packaging machine is to fill various types of beverages, including carbonated drinks, juices, and non-carbonated beverages. It can fill a wide range of bottle sizes, offering great flexibility for manufacturers. This beverage packaging equipment is capable of handling both still and sparkling beverages, making it an ideal choice for manufacturers of soda, sparkling water, and other beverages. The filling process is optimized for speed without sacrificing quality, ensuring efficient production and meeting high-demand production schedules.

Advantages of the Beverage Filling Machine

The MIC 12-1 beverage packaging machine offers several advantages, making it a top choice for beverage producers:

1、High Efficiency

With its rotary design, the carbonated beverage filling machine offers quick filling cycles, significantly boosting production rates.

2、Precision

The advanced filling system ensures each bottle receives the exact volume of liquid, maintaining product consistency and reducing waste.

3、Flexibility

Capable of filling both carbonated and non-carbonated beverages, the machine is versatile and adaptable to different production needs.

4、Durability

Built with high-quality materials, the beverage packaging equipment is designed to withstand the rigors of continuous production, providing reliable performance over time.

5、Ease of Operation

The user-friendly control system allows operators to easily monitor the filling process, adjust settings, and perform routine maintenance tasks with minimal effort.

With the MIC 12-1 beverage packaging machine, Jiangsu Mic Machinery continues to deliver innovative, high-performance equipment that enhances productivity, reduces downtime, and ensures top-quality beverage production.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

|

Can diameter range |

Ф40-90MM |

|

Can height |

92-168MM |

|

Dimension |

1800*1300*1950mm |

|

Weight |

1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |