2.Key Features of Our Blowing Filling Capping 3 in 1 Machine

3.Why Choose Jiangsu Mic Machinery?

4.Blowing Filling Capping Machine Technical parameter

5.Versatile Applications of the Combi-block Blowing Filling Capping Machine

6.What is a Blowing Filling Capping Machine?

7.Contact Us for a Customized Blowing Filling Capping Solution

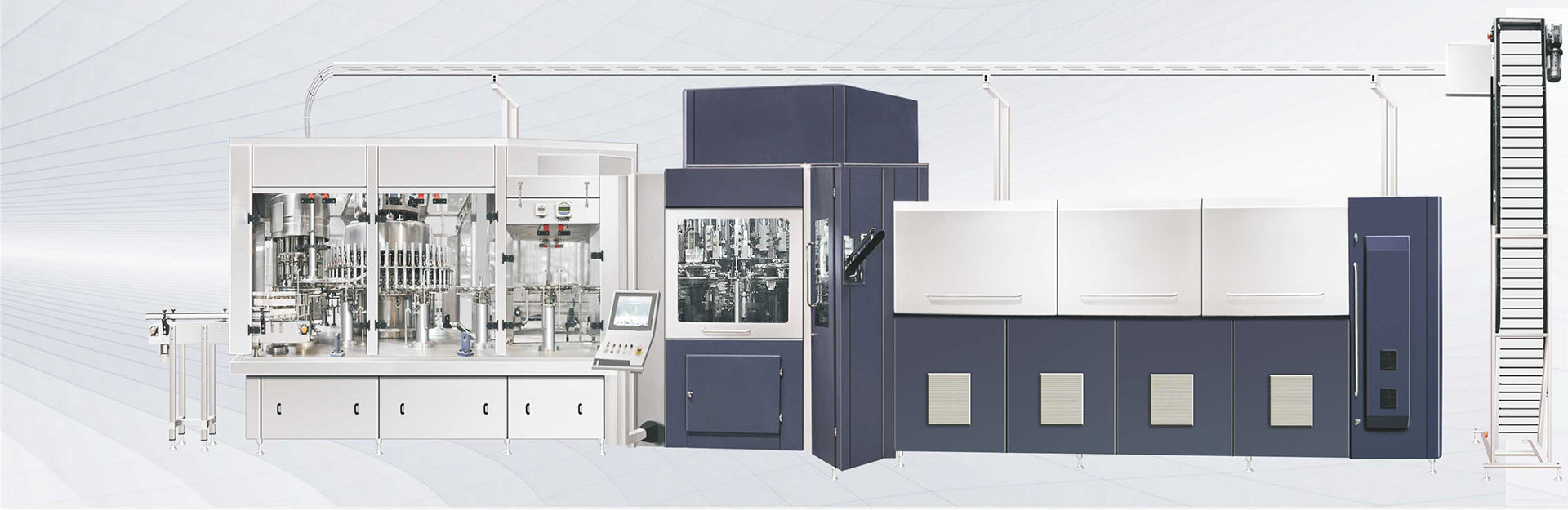

Blowing Filling Capping Machine-Integrated Solutions for Efficient Bottle Production by Jiangsu Mic Machinery

At Jiangsu Mic Machinery, we specialize in the design and manufacture of advanced blowing filling capping machines for the beverage, food, and pharmaceutical industries. Our blowing-filling-capping machine systems are designed to streamline the entire packaging process by integrating bottle forming, filling, and capping into a single automated system, reducing labor, improving efficiency, and ensuring high-quality standards.

Whether you're producing bottled water, soft drinks, or other beverages, our machines provide superior performance and flexibility, making them ideal for businesses looking to scale production while minimizing operational costs.

🏭 Key Features of Our Blowing Filling Capping 3 in 1 Machine

-

High Efficiency: The blowing filling capping 3 in 1 machine combines three distinct operations into a single unit, allowing for faster production with reduced manpower and minimal risk of contamination.

-

PET Bottle Compatibility: Our PET bottle blowing filling capping machine is designed to handle a wide range of PET bottles, accommodating various sizes and shapes with ease. This versatility makes it suitable for industries ranging from beverages to personal care products.

-

Precise Filling Technology: With advanced filling systems, our automatic blowing filling capping machine ensures that each bottle is filled with the precise amount of liquid, reducing wastage and ensuring high standards of hygiene.

-

Hygienic Design: The integrated design eliminates the need for external conveyors and systems, ensuring a compact layout that reduces the risk of contamination.

-

Energy Efficiency: Our blowing-filling-capping machine systems are engineered to minimize energy consumption without compromising production speed or bottle quality, making them both environmentally friendly and cost-effective.

🛠 Why Choose Jiangsu Mic Machinery?

|

As a leading manufacturer of blowing filling capping machines, Jiangsu Mic Machinery offers advanced technology solutions for efficient and cost-effective production. Our machines are built to the highest quality standards, featuring:

|

Blowing Filling Capping Machine Technical parameter

| Number of Working Positions | Blowing 8, Filling 32, Capping 10 |

| Rated Capacity | 18000BPH (600ml) |

| Filling Method | Gravity Filling |

| Applicable Bottle | PET bottle, Diameter of bottle: Φ50~Φ92mm Height of bottle: 150-320mm |

| Applicable Cap | Normal Standard Cap |

| Installed Power | 200KW |

📞 Contact Us for a Customized Blowing Filling Capping Solution

Looking to optimize your bottling process? Jiangsu Mic Machinery offers a range of customizable blowing filling capping machine solutions that integrate seamlessly into your production line. Our expertise in providing high-efficiency bottling systems ensures that your business can scale production without compromising quality or hygiene standards.

📧 Email: lewis@micmachinery.com

📞 Phone: 0086-13961211672