Why Choose Mic Machinery’s Beer Canning Systems?

Flow Diagram OF Beer Canning Filling Machine

Benefits of Our Beer Canning Machines

Customization & Engineering Support

After-Sales Support & Global Service

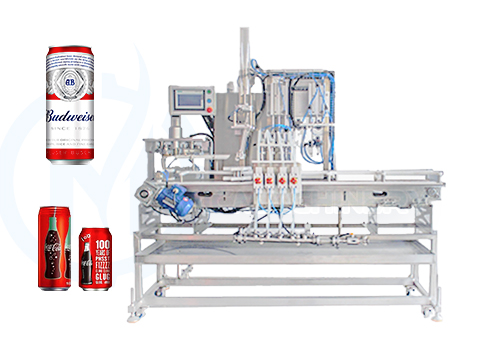

What Is A Beer Canning Filling Machine?

A beer canning filling machine is specialized equipment designed to fill and seal beer in cans, ensuring freshness, foam control, and carbonation retention. These machines are essential for craft breweries and beverage manufacturers looking for reliable, hygienic, and efficient canning systems. Whether you're an independent brewer or a large-scale manufacturer, a robust beer can packaging machine streamlines your production line.

At Jiangsu Mic Machinery, we design systems to meet a wide range of production needs — from manual tabletop models to fully automated lines.

📐 Machine Types We Offer

🔹 Automatic Beer Canning System

Fully automated systems that support CO₂ purging, integrated seaming, and continuous filling — the ideal choice for high-volume operations.

🔹 Semi-Automatic Canning Machine

Cost-effective for medium-scale production. Combines speed and control with easy operability. Perfect for growing craft breweries.

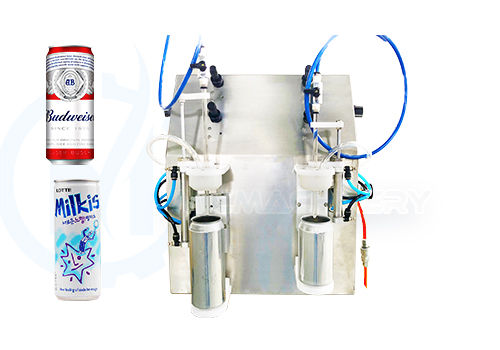

🔹 Tabletop Beer Canning Machine

Compact, portable, and ideal for nano-breweries or testing new recipes. A popular choice for those starting out with a single beer canning machine setup.

Application Industries

Our beer canning filling machines are ideal for: Craft beer producers Mid-size and commercial breweries Mobile canning services Pilot plants and product R&D Soft drink and cider manufacturers Whether you need a tabletop beer canning machine for small batches or a modular solution for your production facility, we’ve got the right model for you. |

Why Choose Mic Machinery’s Beer Canning Systems?

Choosing the right canning system is crucial for scaling your brewery while maintaining product consistency. Our machines are engineered with durability, sanitation, and efficiency in mind. Built from high-grade stainless steel and integrated with advanced control systems, our equipment is designed to grow with your business.

Benefits Include:

-

🍻 Seamless integration with your existing brewing setup

-

🔄 Modular expansion for future upgrades

-

🧽 Easy to disassemble and clean

-

🧊 Foam control for carbonated beverages

-

📉 Reduced oxygen exposure and waste

-

🚀 Reliable, non-stop filling performance

We also provide full technical support, spare parts, and machine customization based on your production goals, batch sizes, and container types. For new brewers, our tabletop beer canning machine is an excellent starting point.

| Model | MIC 12-1 | MIC 18-1 | MIC 18-6 | MIC 24-6 | MIC 32-8 | MIC 40-10 | MIC 4-4-1 | MIC semi automatic | |

| Application | Beer, Carbonated Beverage, Gas Drinks, Sparking Water, And So On | ||||||||

| Packing Type | Aluminum Cans, Metal Cans, Tin Cans, Pet Cans Etc | ||||||||

| Speed | 1000-2000 | 1000-2500 | 3000-6000 | 4000-8000 | 6000-10000 | 8000-15000 | 1000-1500 | ||

| CPH | CPH | CPH | CPH | CPH | CPH | CPH | |||

| Filling Arrange | 180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) | ||||||||

| Power | 1.1kw | 1.5kw | 2.5kw | 3.5kw | 4.2kw | 5.5kw | 2.0-3.5kw | ||

| Size | 1.8*1.3*1.95 (M) | 1.9*1.3*1.95(M) | 2.3*1.4*1.9(M) | 2.58*1.7*1.8(M) | 2.8*1.7*1.95(M) | 3.0*1.9*2.1(M) | 2.2*1.15*2.05(M) | 5.75*5.5*4.8(M) | |

| Weight | 1800KG | 2100KG | 2500KG | 3000KG | 3800(KG) | 4500(KG) | 550(KG) | 15(KG) | |

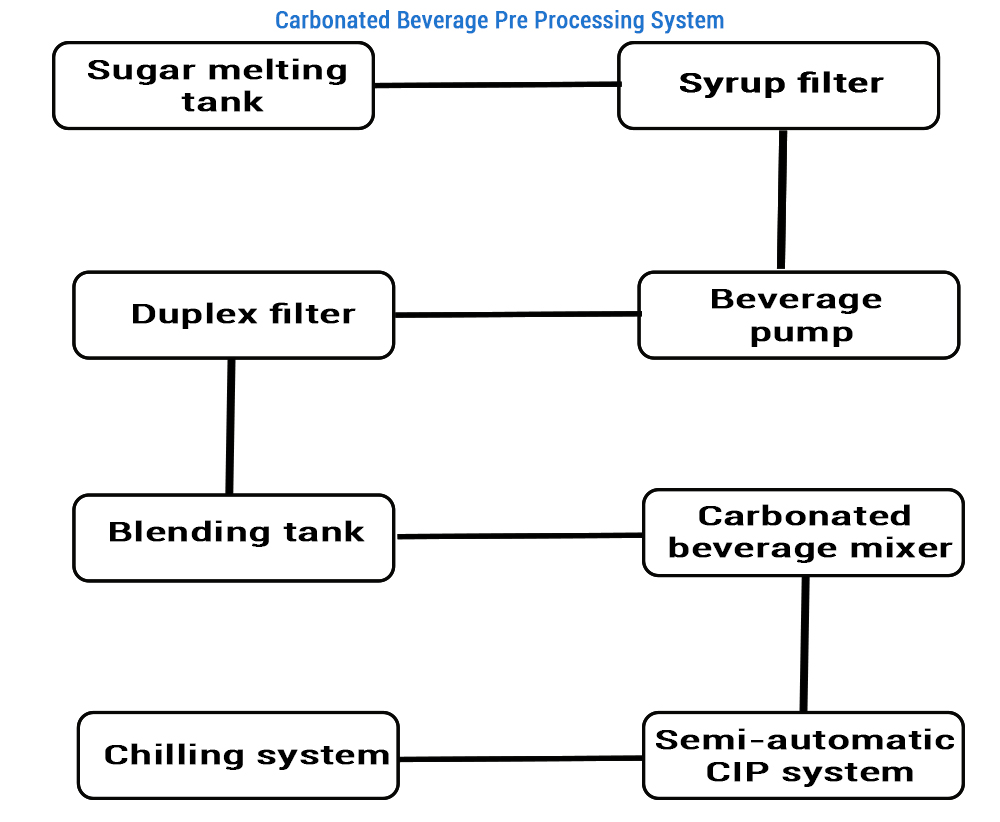

🍻Flow Diagram OF Beer Canning Filling Machine

|

Carbonated Beverage Pre Processing System

|

|

|

|

|

|

|

|

|

|

Warm Irrigation Machine

|

|

|

|

|

|

Shrink sleeve labeling machine

|

|

Laser Batch Coding Machine

|

|

Wrap packing machine/Carton packing machine

|

|

|

|

|

|

Customization & Engineering Support

We engineer every machine based on your specific can size, line layout, and throughput requirements. Additional modules like rinsers, nitrogen dosers, date coders, and shrink labelers can be integrated seamlessly. Can diameter/height customization Optional auto can feeding system Remote diagnostics and PLC controls CE/FDA/GMP-compliant design available Whether you require a beer can packaging machine for export-ready cans or a compact in-house solution, we have the tools and expertise to support you. |

📞 Get Your Quote Today

Whether you're starting your first canning line or upgrading an existing one, Jiangsu Mic Machinery is your trusted partner. From small-batch units to industrial filling systems, we ensure your beer is packaged with care and consistency.

👉 Contact us today to discuss your production needs, request a free consultation, or get a detailed quotation based on your desired beer canning machine price and output requirements.

|

An Automatic Beer Canning Machine efficiently fills, seals, and sanitizes beer cans with minimal manual intervention. It ensures accurate fills, fast production speeds, and improved hygiene, making it ideal for breweries of all sizes. With advanced control systems, it offers precise filling, airtight seals, and versatility for various can sizes. This machine enhances productivity and consistency while reducing labor costs. |

|

A beer can filling machine is designed to automate the beer canning process, ensuring precise filling with minimal foam and spillage. It improves efficiency, reduces labor costs, and maintains the quality of the beer, making it ideal for high-volume breweries and packaging operations. |

|

A beer canning system automates the entire canning process, including filling, sealing, and labeling. It ensures high-speed production, precise filling, and minimal foam, improving efficiency and consistency. Ideal for breweries, it enhances packaging quality and reduces labor costs.

|

|

Beer canning equipment includes machines for filling, sealing, and labeling beer cans. Designed for high-speed production, it ensures precise filling, minimal foam, and airtight seals. This equipment improves efficiency, reduces waste, and enhances the quality of packaged beer. |

|

Our craft beer canning machine is built for small breweries, offering high precision and efficiency. It ensures accurate fill levels, preserving the quality and freshness of your craft beer while streamlining the canning process for smooth, reliable operation. |

|

A craft beer canning machine is tailored for small breweries, offering precision, efficiency, and flexibility. It ensures accurate filling and secure sealing to preserve the flavor and carbonation of craft beer. Ideal for small-batch production, it boosts quality and productivity. |

|

A beer can filling machine efficiently fills cans with beer, ensuring precise volume control and minimal waste. It is designed for high-speed production, featuring automated processes for filling, sealing, and capping, making it ideal for breweries looking to scale operations. |

|

The manual beer can filling machine is an ideal solution for small breweries or craft brewers. It offers precise, hands-on control over the filling process, ensuring accurate fill levels and minimal waste. Perfect for low-volume production with high-quality results. |

|

Our manual beer canning machine offers a cost-effective solution for small-scale breweries. Easy to operate, it ensures precise capping, and sealing of beer cans. Perfect for craft brewers looking to scale up production with minimal automation. |