2.Features of Our Bottle Blowing Machines

4.Bottle Blowing Machine Parameters

5.What Is a Bottle Blowing Machine?

6.Why Choose Jiangsu Mic Machinery?

8.Contact Us for Customized Bottle Blowing Solutions

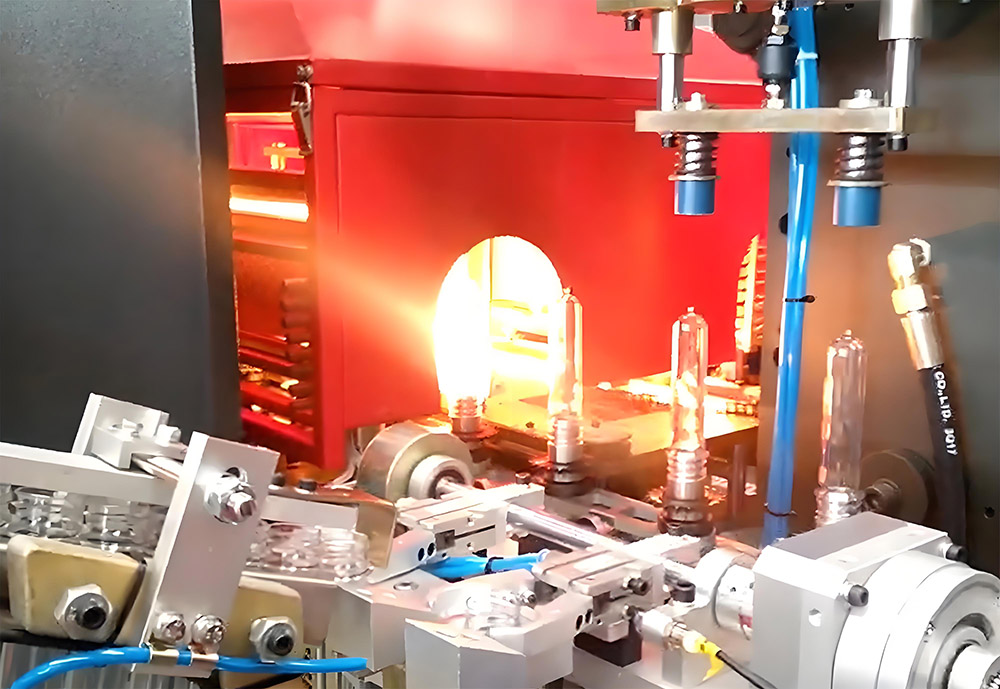

Bottle Blowing Machine-Efficient and High-Precision Bottle Manufacturing Solutions by Jiangsu Mic Machinery

At Jiangsu Mic Machinery, we specialize in the design and manufacture of advanced bottle blowing machine systems that cater to a wide range of industries including beverage, cosmetics, and pharmaceuticals. Our plastic bottle making machines are engineered to deliver high-speed, high-efficiency production lines that meet international quality standards. Whether you’re producing PET bottles, plastic jars, or water bottles, our bottle manufacturing machine solutions are designed to maximize performance, minimize waste, and reduce operational costs.

From PET bottle blowing machines for small-scale production to automatic pet bottle blowing machines for large-scale factories, we provide the ideal solution for your specific needs.

🔧 Features of Our Bottle Blowing Machines

-

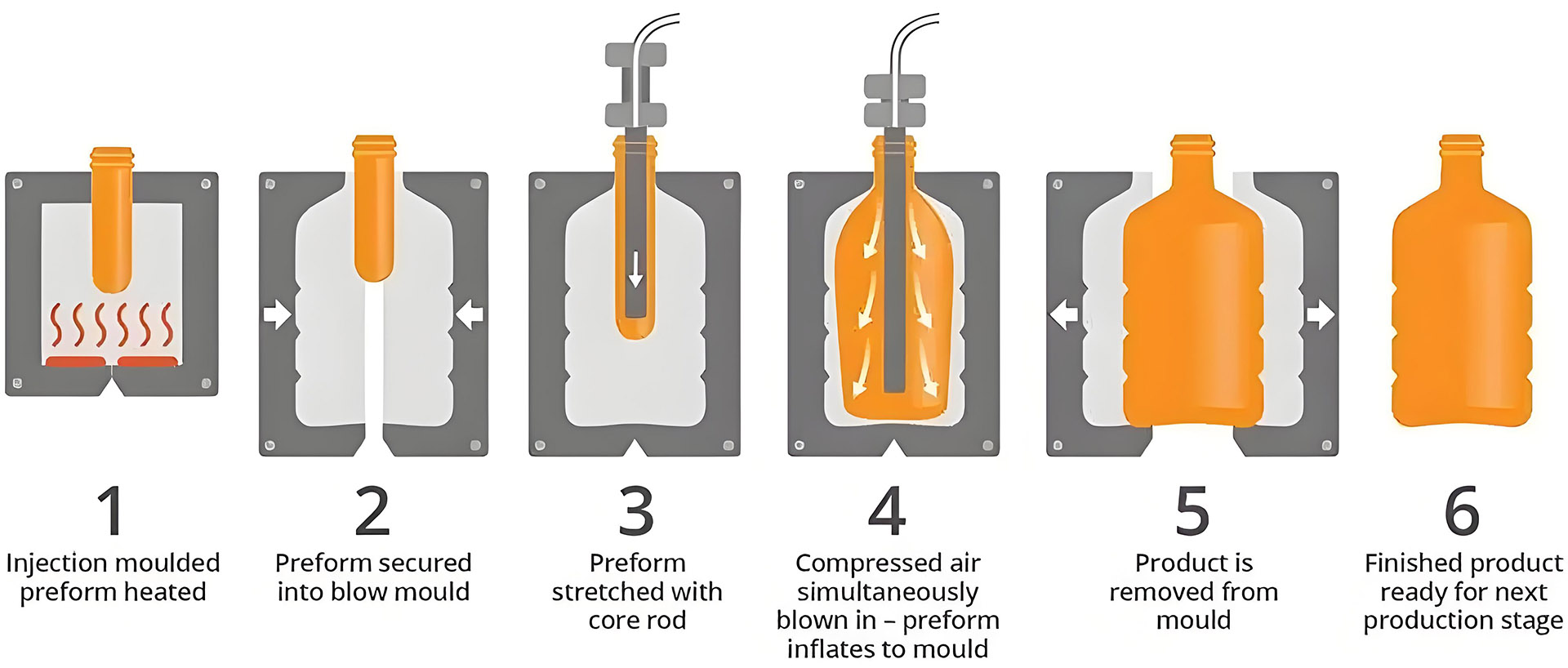

Precision and Efficiency: Our plastic bottle manufacturing machine ensures high precision in bottle blow molding, with optimized heating and cooling processes for reduced energy consumption.

-

Versatility: From PET bottle making machines to pet jar blowing machines, our systems can handle a wide range of bottle shapes and sizes, accommodating various requirements in plastic bottle production.

-

Energy Efficient: Designed to minimize energy consumption, our plastic bottle blowing machines utilize advanced technology to provide a cost-effective solution for high-output operations.

-

Durability: Built with high-quality stainless steel and advanced components, our plastic bottle manufacturing equipment ensures long-lasting performance with minimal maintenance.

-

Customizable Options: We offer plastic bottle molding machine solutions tailored to your production needs, whether you are manufacturing bottles for water, juices, or even household products.

🌍 Applications and Industries

|

Our plastic bottle blow molding machines are used for the production of:

|

Bottle Blowing Machine Parameters

| model | 15L- | 1L-R600 | 1L-2400 | 0.8L-2800 | 1.5L-1800 | 2.5L-1500 | 5L-1500 | 0.8L-4500 | 0.8L-6000 | 2L-R-4500A | 0.8L-9000 | R-12000A | R-15000A |

| weight of preform | 170 | 16 | 16 | 16 | 35 | 70 | 116 | 16 | 16 | 60 | 16 | 16 | 16 |

| No. of preform holder | 62 | 40 | 40 | 42 | 40 | 54 | 66 | 84 | 86 | 110 | 114 | 148 | 182 |

| Neck size | 30-80 | 18-38 | 18-38 | 18-38 | 26-50 | 18-45 | 25-45 | 18-38 | 15-38 | 28-42 | 18-38 | 20-30 | 20-30 |

| Max height of preform | 260 | 130 | 130 | 130 | 150 | 180 | 210 | 130 | 130 | 190 | 130 | 150 | 150 |

| Max inner diameter of bottle | 265 | 85 | 85 | 85 | 130 | 125 | 210 | 75 | 75 | 140 | 70 | 75 | 75 |

| Max height of bottle | 500 | 265 | 265 | 265 | 320 | 370 | 350 | 265 | 265 | 350 | 280 | 270 | 270 |

| No. of heating box | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 4 | 6 | 4 | 6 |

| No.of infrared lamp | 48 | 16 | 16 | 16 | 32 | 40 | 48 | 32 | 32 | 32 | 48 | 32 | 48 |

| Heating powe | 30 | 15 | 15 | 20 | 25 | 18 | 48 | 30 | 30 | 50 | 50 | 48 | 60 |

| Specified power consupiorl | 48 | 32 | 32 | 32 | 38 | 20 | 60 | 64 | 64 | 64 | 96 | 75 | 85 |

🔍 Why Choose Jiangsu Mic Machinery?

At Jiangsu Mic Machinery, we pride ourselves on delivering top-quality plastic bottle manufacturing machines with the latest technology and the highest standards of safety and hygiene. Our bottle blowing machines are engineered to meet the demands of various industries, offering:

-

Global Standards: Our bottle blowing machines for sale meet international quality standards, ensuring your products are packaged to the highest specifications.

-

Expert Engineering: With decades of experience, our team provides tailored solutions for all types of bottle production, offering advice and support to help optimize your operations.

-

Comprehensive Service: From consultation and equipment customization to installation and maintenance, we offer a complete service to ensure your production runs smoothly.

📞 Contact Us for Customized Bottle Blowing Solutions

Looking to expand your production capabilities with a plastic bottle blowing machine? At Jiangsu Mic Machinery, we provide automatic bottle blowing machine solutions that meet your unique needs. Our systems offer precision, reliability, and efficiency, backed by our industry expertise and customer service.

📧 Email: lewis@micmachinery.com

📞 Phone: 0086-13961211672