Edible Oil Filling Machine

1.Edible Oil Filling Machine – High-Precision Oil Packaging Solutions

2.Reliable and Versatile Filling Technology

3.Why Choose Jiangsu Mic Machinery?

4.Flow Diagram OF Edible Oil Filling Machine

5.Features of Our Edible Oil Filling Machine

Edible Oil Filling Machine – High-Precision Oil Packaging Solutions

At Jiangsu Mic Machinery, we specialize in manufacturing high-performance edible oil filling machines tailored to meet the diverse needs of oil producers worldwide. Whether you're filling sunflower, coconut, mustard, or olive oil, our advanced systems provide accurate, hygienic, and efficient packaging solutions for small and large-scale production. As leading edible oil filling machine manufacturers, we focus on quality, durability, and adaptability across various oil types and bottle sizes.

✅ Reliable and Versatile Filling Technology

Our equipment is engineered to handle a wide range of liquid viscosities. From free-flowing sunflower oil to thicker oils like coconut or olive oil, the system ensures precise volume control and drip-free operation. The oil filling and capping machine integrates seamlessly into production lines, automating the processes of dosing, filling, capping, and sometimes even labeling, depending on your line configuration.

Whether you need a coconut oil bottle filling machine or a complete edible oil packing unit, our machines deliver consistent output with low maintenance and high reliability. We offer both linear and rotary designs to suit your factory layout and production capacity.

🛠 Why Choose Jiangsu Mic Machinery?As experienced edible oil filling machine manufacturers, we are committed to providing machines that combine advanced technology, durable construction, and user-friendly design. We help businesses increase efficiency, reduce wastage, and improve product consistency. Our team provides:

|

Bottled Oil Filling Machine:

| Model | MIC 18-4 | MIC 18-6 | MIC 24-6 | MIC 32-8 | MIC ZF8 |

| Application | Various edible oils, olive oil, peanut oil, coconut oil, etc. | ||||

| Packing Type | Plastic Bottle | Plastic and glass Bottle | |||

| Speed | 1800-2200BPH based on 5L | 3000-6000BPH | 4000-8000BPH | 10000BPH | 50-1000ml(Use 1000ml Piston Cylinder) |

| Filling Arrange | 250ml, 330ml, 355ml, 500ml, 120z, 16oz, 1L and so on (0.1-1L) | ||||

| Power | 1.5KW | 3.7KW | 3.7KW | 4.2KW | 3kw |

| Size | 2570*2300*2650(mm) | 2300*1400*1900(mm) | 2580*1700*1900(mm) | 2800*1700*1950(mm) | 2000*1400*2500(mm) |

| Weight | 5000Kg | 2500KG | 3000KG | 3800KG | 1000kg |

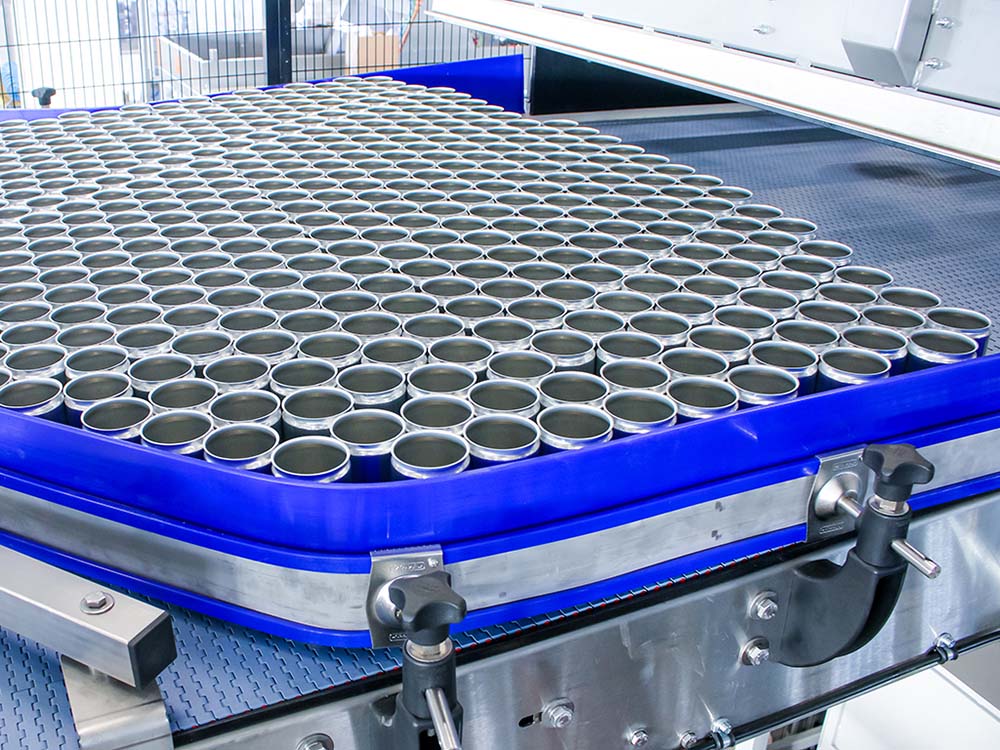

Can Oil Filling Machine:

| Model | MIC 18-6 | MIC 24-6 | MIC 32-8 |

| Application | Various edible oils, olive oil, peanut oil, coconut oil, etc. | ||

| Packing Type | Aluminum cans, tin can etc | ||

| Speed | 3000-6000CPH | 4000-8000CPH | 10000CPH |

| Filling Arrange | 130ml, 25(iml, 330ml,355ml, 500ml, 120z,16oz,1L and so on (0.1-1L) | ||

| Powder | 3.7KW | 3.7KW | 4.2KW |

| Size | 2300*1400*1900(mm) | 2580*1700*1900(mm) | 2800*1700*1950(mm) |

| Weight | 2500KG | 3000KG | 3800KG |

Flow Diagram OF Edible Oil Filling Machine

|

Plastic Bottle Blowing Machine

|

|

|

|

|

|

|

|

Oil Pet Bottle Filling Machine

|

|

Oil Glass Bottle Filling Machine

|

|

Hot melt glue labeling machine

|

|

Shrink sleeve labeling machine

|

|

Laser Batch Coding Machine

|

|

Wrap packing machine/Carton packing machine

|

|

|

|

|

|

💡 Features of Our Edible Oil Filling Machine

🧴 Bottle Filling OptionsWe support a wide range of packaging formats. From small glass bottles to large PET containers, our bottle oil filling machine adapts easily. The pet bottle oil filling machine is particularly popular for edible oil brands looking to scale production efficiently. Additionally, our olive oil bottling equipment ensures the sensitive nature of olive oil is preserved throughout the filling process.

|

|

💰 Competitive Pricing and ROIOur solutions are not only efficient but also cost-effective. The edible oil filling machine price varies based on configuration, capacity, and automation level, but every machine is designed to deliver long-term value. Whether you're interested in a basic setup or an integrated edible oil bottle packing machine, we’ll help you optimize performance without overspending. Contact us for an accurate cooking oil packing machine price based on your specific production needs.

🏭 Complete Packaging LinesJiangsu Mic Machinery also offers full turnkey solutions. Beyond just the filler, we supply complete edible oil packing units that include Bottle blowing machine, cappers, labelers, inkjet printers, and shrink wrappers. For brands seeking consistent branding and high throughput, our systems ensure that from filling to final sealing, each bottle meets the highest standards. |

|

|

|

🌿 Applications

|

📞 Get a Quote Today

Looking for a reliable oil bottling machine price or a custom solution tailored to your production line? Contact Jiangsu Mic Machinery today and explore how our edible oil filling machines can streamline your packaging process and boost productivity.

📧 Email:

- lewis@micmachinery.com

📞 Phone:

-

0086-13961211672

|

The MIC 18-4 oil filling machine offers precision and efficiency with a capacity of 1800-2200 bottles per hour. Ideal for edible oils, it features advanced automation, reliable performance, and easy operation for seamless production. |

|

The MIC 18-6 cooking oil filling machine delivers high-speed performance, filling 3000-6000 bottles per hour. Perfect for cooking oil production, it ensures accuracy, durability, and easy operation for optimized efficiency. |

|

The MIC 24-6 edible oil packing machine ensures high efficiency, packing 4000-8000 containers per hour. Designed for precision and durability, it’s ideal for large-scale edible oil production and seamless operation.

|

|

The MIC 24-6 Rotary Type automatic oil filling machine offers high-speed precision, filling 4000-8000 containers per hour. Perfect for edible oils, it combines durability, efficiency, and easy operation for seamless production. |

|

The MIC palm oil filling machine offers efficient, high-speed filling at 1800 bottles per hour. Designed for palm oil production, it ensures accuracy, durability, and seamless operation, optimizing your packaging process. |