2.Trusted Manufacturer for Global Beverage Brands

3.Craft Beer Brewing Equipment

5.Distilled Spirit Production Equipment

7.Request Your Custom Solution

Alcoholic Drink Production Machinery-Custom Brewing, Distillation & Bottling Equipment by Jiangsu Mic Machinery

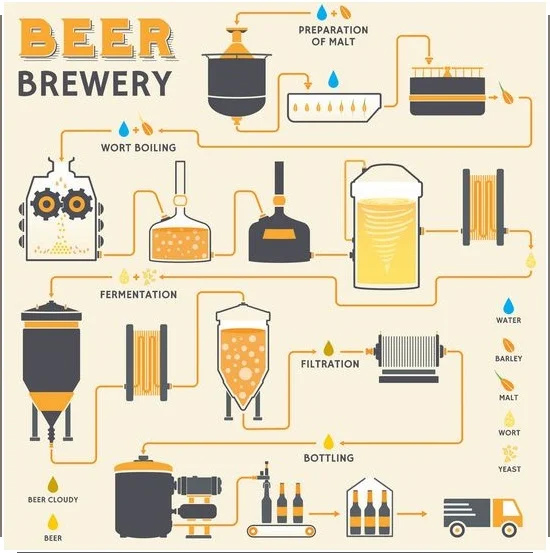

At Jiangsu Mic Machinery, we design and manufacture comprehensive solutions for the brewing, fermentation, distillation, filtration, and packaging of alcoholic beverages. From craft beer to premium spirits and fine wines, our equipment is trusted by microbreweries, wineries, and distilleries worldwide. Whether you're launching a boutique operation or expanding a high-capacity facility, we offer modular and turnkey systems built for safety, efficiency, and compliance with international food-grade standards.

🏭 Trusted Manufacturer for Global Beverage Brands

Jiangsu Mic Machinery has helped clients across 60+ countries set up scalable brewing and distillation plants. As a professional supplier of craft beer brewing equipment, wine production equipment for wineries, and rum and gin processing machinery, we provide CE/ISO-certified machinery backed by engineering expertise and after-sales service.

Whether you are starting a new operation or upgrading your facility, our team can deliver the right combination of technology, reliability, and support.

|

🍷 Wine Production Equipment

For winemakers, Jiangsu Mic Machinery offers fully integrated wine production equipment for wineries, ideal for red, white, and sparkling wines. From grape processing to final packaging, our systems ensure purity, flavor preservation, and ease of operation.

Our wine equipment includes: Grape crushing and wine press machine: Gentle extraction for maximum juice yield without damaging grape skin tannins. Wine fermentation tanks and bottling line: Temperature-controlled tanks and bottling units with nitrogen flushing and corking options. Wine filtration and aging system: Multi-stage filtration and barrel or stainless aging tanks to optimize taste and shelf stability. Red and white wine processing equipment: Configurable solutions for handling various grape types and production styles. |

🔍 Frequently Asked Questions

What machines are used in alcoholic beverage production?

Common machines include brewhouses, fermentation tanks, crushers, filtration systems, distillation units, pasteurizers, and filling/labeling machines—each tailored to the specific beverage.

How do I choose equipment for beer or wine processing?

Consider your beverage type, volume needs, packaging format, and available space. Our team helps design optimal solutions based on these factors.

Can one production line handle multiple types of alcohol?

Yes, with proper modular design. For example, a shared line can be used for wine and beer fermentation. However, distilled spirits require separate stainless steel alcohol distillation system components due to unique process conditions.

What’s the difference between beer and spirit equipment?

Beer systems prioritize fermentation and cold filling, while spirits require heat-based distillation, ethanol filtration, and specialized bottling for higher-proof products.

📞 Request Your Custom Solution

Looking to launch or upgrade your beer, wine, or spirits line? Contact Jiangsu Mic Machinery today to build your tailored solution—from grape crushing and wine press machine units to complete microbrewery fermentation and bottling system packages.

📧 Email: lewis@micmachinery.com

📞 Phone: 0086-13961211672