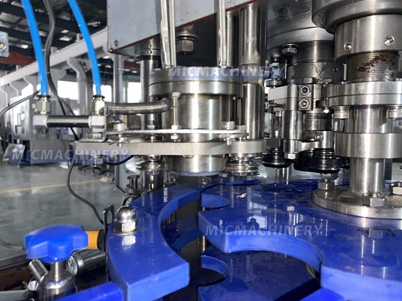

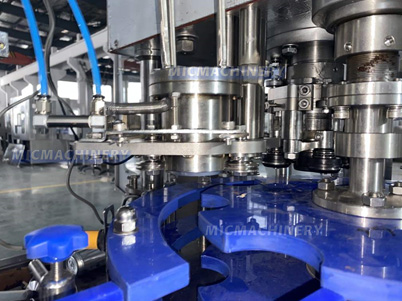

MIC 12-1 Beverage Filling Equipment (1000-2000CPH)

Machine is Suitable For

The beverage filling equipment is designed for a wide range of beverages, including carbonated drinks, juices, flavored water, and non-carbonated beverages. Ideal for medium to high-volume production lines, this beverage packaging machine is highly versatile and ensures seamless integration into various manufacturing environments. It is suitable for filling glass, PET, or plastic bottles and can handle different bottle sizes with ease, making it an excellent choice for manufacturers seeking efficiency and quality in their production processes. The automatic beverage filling machine is perfect for companies looking to optimize their production capacity while maintaining the highest standards of hygiene and consistency.

|

|

Can filling seaming machine foaming device |

|

Can filling seaming machine liquid tank A Can Filling Seaming Machine Liquid Tank is a storage component that holds the beverage (such as beer or soda) before it is filled into cans. Positioned above the filling station, the tank ensures a steady and consistent supply of liquid to the filling machine. It is designed to maintain the correct pressure and temperature to ensure accurate fills and prevent spillage. The liquid tank typically features precise control systems to regulate liquid levels and flow rates, ensuring smooth and efficient operation of the canning process. |

|

|

|

Lid feed system A Lid Feed System automatically delivers and positions lids onto cans before they are sealed. It ensures accurate lid alignment, improves production speed, and works seamlessly with the seaming machine to provide secure, airtight seals, enhancing efficiency and reducing labor costs. |

Working Principle of the Beverage Filling Machine

The automatic beverage filling machine operates with advanced technology to ensure precise and reliable filling. The machine features a rotary system, where bottles are automatically fed onto the filling turntable. The filling process is controlled by an intelligent control system, which manages the pressure, flow rate, and filling time to ensure accurate liquid levels in each bottle. This machine is designed to minimize product spillage and wastage while filling beverages at high speeds. The incorporation of a vacuum or pressure-based filling mechanism ensures that carbonated and non-carbonated beverages are filled without losing carbonation or flavor, maintaining the integrity of the product.

Advantages of the Beverage Filling Machine

The beverage filling equipment offers numerous advantages that make it an essential addition to beverage production lines:

1、High Efficiency

The beverage packaging machine is engineered for high-speed operation, enabling manufacturers to meet large production demands with minimal downtime.

2、Precise Filling

The machine’s advanced filling system ensures consistent and accurate filling, minimizing product wastage and maintaining uniform quality.

3、Versatility

Capable of handling a wide range of beverage types and bottle sizes, the automatic beverage filling machine offers flexibility in production.

4、Durability

Made from high-quality materials, the machine is built to withstand continuous use, offering long-term reliability and performance.

5、Ease of Operation

The user-friendly interface allows operators to monitor and control the filling process, making it easy to maintain optimal production conditions.

With the beverage filling equipment, Jiangsu Mic Machinery delivers a high-performance solution that combines precision, efficiency, and flexibility, helping beverage manufacturers improve their production processes while ensuring top-quality products.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |