2.What Types of Water Treatment Machines Are Available for Drinking Water?

3.What Is Drinking Water Treatment Equipment?

4.Why Is Drinking Water Treatment Important?

5.Can Water Treatment Machines Remove Bacteria and Heavy Metals?

6.How to Choose the Right Water Treatment Equipment?

7.Trusted Manufacturer for Industrial and Commercial Water Systems

8.How to Maintain a Drinking Water Treatment Machine?

9.Get a Customized Water Purification Solution Today

Drinking Water Treatment Equipment-High-Efficiency Water Purification Solutions by Jiangsu Mic Machinery

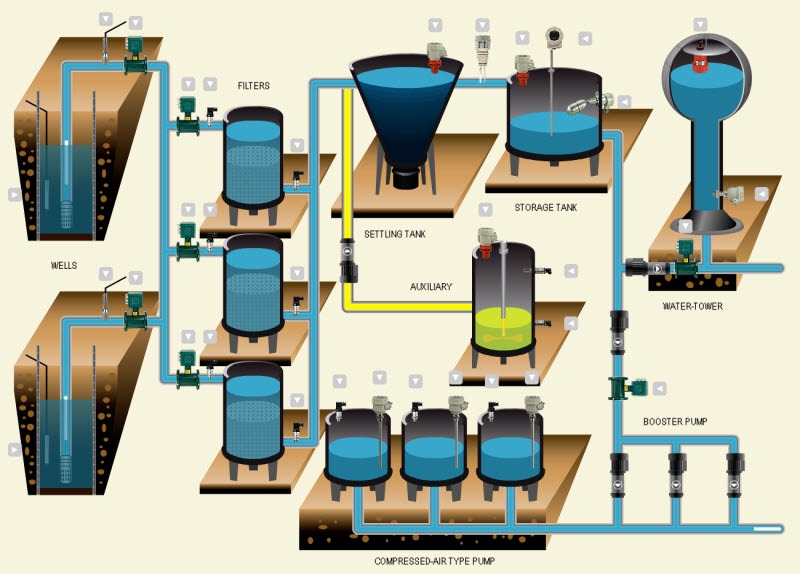

At Jiangsu Mic Machinery, we specialize in designing and manufacturing advanced drinking water treatment equipment for factories, commercial facilities, and large-scale municipal operations. Our equipment ensures safe, purified water for human consumption, meeting both international health standards and local water safety regulations.

Whether you're building a water bottling plant, upgrading an industrial facility, or installing purification systems for public spaces, our full-range solutions—including RO systems, filtration units, and UV sterilizers—are trusted for their precision, automation, and durability.

🛠 What Types of Water Treatment Machines Are Available for Drinking Water?

At Jiangsu Mic Machinery, we manufacture several types of water treatment machine for drinking, including:

-

Reverse Osmosis (RO) Systems – Removes dissolved salts, heavy metals, and bacteria.

-

UV Sterilization Units – Kills 99.9% of microorganisms without chemicals.

-

Activated Carbon Filters – Eliminates chlorine, odor, and organic contaminants.

-

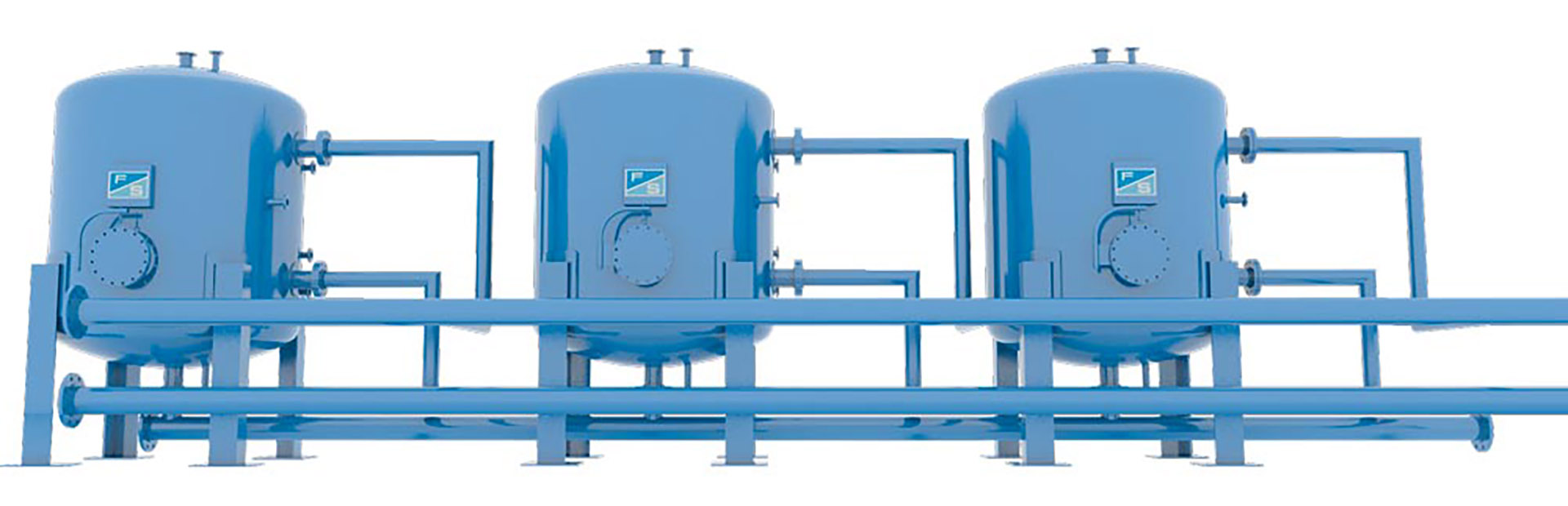

Sand and Multimedia Filters – Remove sediment, rust, and turbidity.

-

Automatic Water Softeners – Prevent scaling from calcium and magnesium.

These systems can be integrated into a single automatic water treatment equipment line, fully managed by PLC touch-screen control with remote monitoring options.

🦠 Can Water Treatment Machines Remove Bacteria and Heavy Metals?

Yes. Our advanced industrial water filter equipment combines RO membranes with UV disinfection and activated carbon to effectively remove:

-

Bacteria & Viruses: UV and RO eliminate over 99.9% of pathogens

-

Heavy Metals: Including lead, arsenic, mercury, and chromium

-

Chemical Residues: Such as chlorine, pesticides, and VOCs

With optimized flow design and multi-stage treatment, we guarantee high-quality output that exceeds global potable water standards.

🧰 How to Maintain a Drinking Water Treatment Machine?

Routine maintenance is key to long-term performance. Here's what we recommend:

-

Filter Replacement: Replace RO membranes every 1–2 years; sediment and carbon filters every 6 months.

-

UV Lamp Change: Every 8,000–10,000 hours for optimal disinfection.

-

System Cleaning: CIP (Clean-in-Place) modules flush the system without disassembly.

-

Operational Monitoring: Pressure gauges, flow sensors, and alarms alert users to potential faults.

All Jiangsu Mic Machinery water systems come with full manuals, video guides, and remote tech support.

📞 Get a Customized Water Purification Solution Today

Whether you need a small commercial water treatment system or a complete water treatment machine for drinking with RO, UV, and automated CIP, we’re here to help. Let Jiangsu Mic Machinery build your trusted solution for clean, safe drinking water.

📧 Email: lewis@micmachinery.com

📞 Phone: 0086-13961211672