Showing 1–9 of 7 results

Nitrogen Dosing Machine

A Nitrogen Dosing Machine is designed to inject nitrogen gas into products to enhance preservation and extend shelf life. Commonly used in food and beverage industries, it prevents oxidation, ensuring quality and freshness.

Learn more

MIC WYD-50 Nitrogen Dosing Machine

The MIC WYD-50 Nitrogen Dosing Machine offers precise nitrogen injection for various packaging applications. With automated control and high efficiency, it ensures consistent product quality, reducing waste and optimizing the packaging process for food, beverage, and pharmaceutical industries.

Learn more

MIC WYD-300 Nitrogen Dosing Equipment

The MIC WYD-300 Nitrogen Dosing Equipment delivers precise nitrogen infusion for packaging, enhancing product quality and shelf life. With advanced automation and reliable performance, it optimizes processes in industries like food, beverage, and pharmaceuticals.

Learn more

MIC WYD-600 Industrial nitrogen dosing

The MIC WYD-600 Industrial Nitrogen Dosing system ensures precise nitrogen infusion for packaging, preserving freshness and stability. With advanced automation and high efficiency, it enhances production in food, beverage, and pharmaceutical industries.

Learn more

MIC WYD-800 Nitrogen Infusion Equipment

The MIC WYD-800 Nitrogen Infusion Equipment delivers precise nitrogen dosing to enhance product stability and shelf life. With advanced automation and high efficiency, it ensures reliable performance for food, beverage, and pharmaceutical packaging.

Learn more

MIC WYD-1200 Nitrogen Dosing Machine

The MIC WYD-1200 Nitrogen Dosing Machine provides precise and efficient nitrogen infusion for packaging applications. With advanced automation and high-speed operation, it enhances product stability and extends shelf life in food, beverage, and pharmaceutical industries.

Learn more

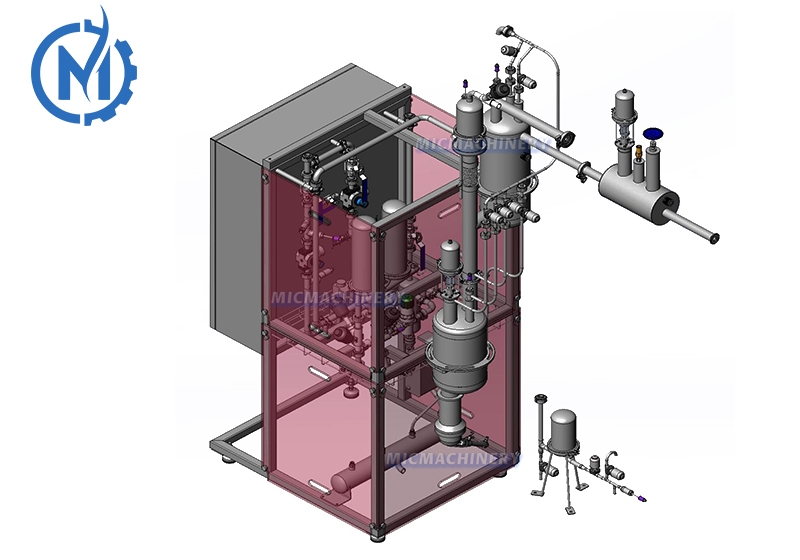

Aseptic Liquid Nitrogen Dosing Equipment

Our Aseptic Liquid Nitrogen Dosing Equipment ensures precise nitrogen infusion while maintaining sterile conditions. Designed for food, beverage, and pharmaceutical packaging, it enhances product stability, freshness, and shelf life with advanced automation and high efficiency.

Learn more