Showing 1–9 of 1 results

Advanced Carbonated Can Filling Machines for Beverage Industries

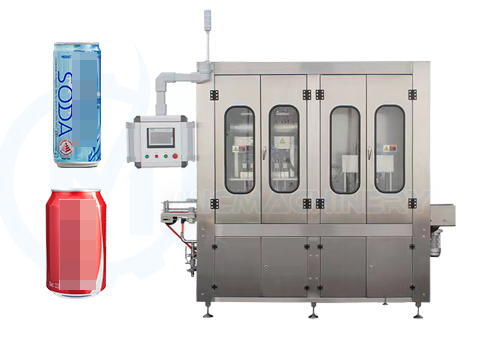

At Jiangsu Mic Machinery, we specialize in delivering high-performance carbonated can filling machine solutions tailored for soda, sparkling water, beer, and other fizzy beverages. With precise pressure control and hygienic design, our machines ensure every can is filled safely, efficiently, and with perfect carbonation retention.

🥤 What Is a Carbonated Can Filling Machine?

A carbonated can filling machine is a specialized system designed to fill cans with carbonated drinks while preserving the CO₂ content. Unlike non-carbonated fillers, these machines maintain specific counter-pressure levels to prevent foam overflow and carbonation loss during the filling process.

|

Our systems are built for: • Soda beverages • Sparkling water • Kombucha and energy drinks • Craft beer and commercial brews Jiangsu Mic Machinery’s soda can filling machine and beer can filling machine models are built to accommodate a variety of can sizes and beverage types while maintaining high filling accuracy and minimal waste. |

⚙️ Key Features of Our Carbonated Can Fillers

|

All of our carbonated can filling machine options are engineered with advanced features: • Counter-pressure filling to retain carbonation • Integrated CO₂ purging and vacuum systems • Precision flow valves for foam-free fills • Seamless integration with can sealing systems • PLC control with user-friendly touchscreens • Sanitary stainless steel construction for food-grade use Whether you're a startup brewery or an international soda brand, our equipment offers scalable options to meet your production goals. |

|

🔄 Linear Can Filling Sealing Machine for Flexible Output

|

For mid-scale operations, our linear can filling sealing machine is an ideal choice. It combines: • Linear filling technology for moderate-speed output • Automatic lid placing and sealing • Adjustable settings for various can volumes • Compact footprint for space-limited facilities This modular system is perfect for companies wanting to maintain high carbonation integrity with lower initial investment. |

📐 Linear Carbonated Can Filling Machine Technical Specifications

| Production Speed | 25CPM/330ml, 20CPM/500ml, 2-piece cans |

| Applicable Can Type | 211 (330ml/500ml) |

| Applicable Cap Type | 202 |

| Filling Heads | 6 |

| Seaming Heads | 1 |

| Filling Valve Structure | Electronic valve |

| Inlet/Outlet Conveyor Height | Inlet: 830mm±50mm, Outlet: 900mm±50mm |

| Mechanical Standards | ISO metric bolts, nuts, and food-grade materials |

| Seaming Device | Oil-free |

| Can Direction | 180° linear |

| Cap Feeding Method | Manual cap placement with simple feeder slot |

| Electrical Control | Accurate filling volume control |

| Fault point alert on human-machine interface | |

| Cap absence detection | |

| Daily/Shift production counter | |

| Circulating CIP cleaning system | |

| Dissolved Oxygen Control | Oxygen increase: ≤20PPB during filling |

| Filling Accuracy | ±2mm |

| Total Power | 1.0KW |

| Voltage | 2-phase 4-wire, 3-phase 220V, 50HZ |

| Weight | 500KG |

| Installation | Flexible mobility, can be fixed after movement |

🍺 Beer Can Filling Solutions

The beer can filling machine models by Jiangsu Mic Machinery are optimized for brewery needs. With enhanced foaming control, oxygen reduction, and precision seaming, you can expect:

• Minimal dissolved oxygen pickup

• Consistent fill volumes with low loss

• Craft beer and microbrew compatibility

• Flexible changeovers between can sizes

We support both manual and automatic beer filling lines depending on your production scale.

🥫 Soda Can Filling Machines with Accuracy & Speed

|

The soda can filling machine line offers high-speed output with exact control over carbonation and liquid flow. Suitable for cola, flavored sparkling drinks, or carbonated energy drinks, these machines help reduce foaming, eliminate product waste, and boost filling efficiency. Options include: • Rotary or linear configurations • Aluminum or tinplate can support • Automatic can feeding and discharge • Customizable fill volumes |

|

🌍 Why Choose Jiangsu Mic Machinery?

With decades of experience in beverage packaging, Jiangsu Mic Machinery is a leading manufacturer of carbonated can filling machine systems in China. Our advantages include:

• Tailor-made production line design

• Exported equipment to 50+ countries

• Dedicated after-sales and spare parts support

• ISO and CE-certified machinery

Whether you're looking for a linear can filling sealing machine, a soda can filling machine, or a full beer can filling machine line, we are your one-stop partner in canning innovation.

📩 Get a Quote for Your Carbonated Can Filling Line

Looking to invest in a reliable carbonated can filling machine that matches your budget and production requirements? Contact Jiangsu Mic Machinery today for a free consultation. We’ll help you build a powerful, efficient, and future-proof beverage packaging line.

📧 Email: lewis@micmachinery.com

🌐 Website: www.micbeveragemachine.com

📞 WhatsApp/Phone: 0086-13961211672