Automatic Vacuum Detection System: Ensuring Packaging Integrity with Precision

⚙ Overview

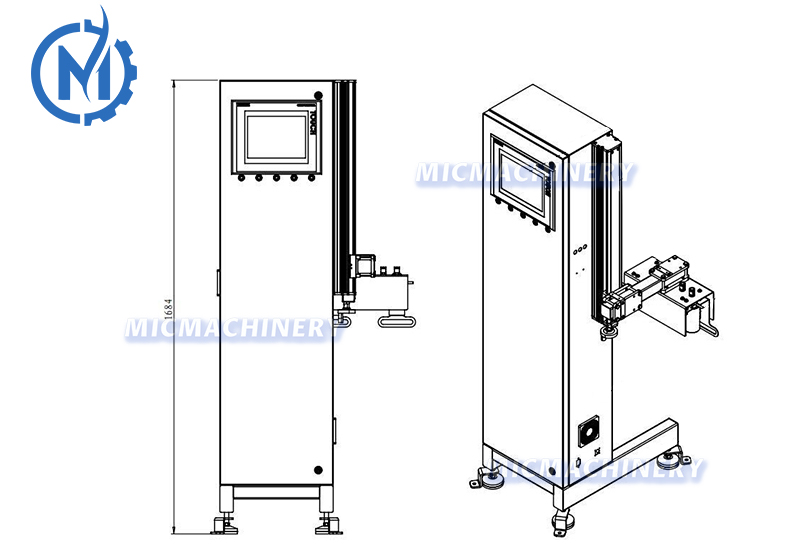

In industries where product quality and safety are paramount, maintaining the integrity of vacuum-sealed packaging is crucial. Our Automatic Vacuum Detection System is engineered to seamlessly integrate into existing production lines, providing real-time monitoring and ensuring each package meets stringent vacuum standards.

⚙ Key Features

Real-Time Vacuum Monitoring

Utilizing advanced sensor technology, the system continuously monitors the vacuum level within each package. This ensures immediate detection of any deviations from the set parameters, allowing for prompt corrective actions.

Seamless Integration

Designed for compatibility, the system can be effortlessly incorporated into various packaging lines, including those handling jars, cans, pouches, and more. Its modular design ensures minimal disruption during installation.

User-Friendly Interface

Equipped with an intuitive control panel, operators can easily set vacuum thresholds, monitor performance metrics, and access diagnostic information, enhancing operational efficiency.

High-Speed Operation

Capable of inspecting up to 300 packages per minute, the system maintains high throughput without compromising accuracy, making it ideal for high-volume production environments.

⚙ Technical Specifications

▪ Detection Method: Non-contact sensor-based vacuum measurement

▪ Inspection Speed: Up to 300 packages per minute

|

|

▪ Vacuum Threshold Range: Customizable based on product requirements

▪ Integration Capability: Compatible with various packaging machines and conveyor systems

▪ Alarm System: Visual and audible alerts for packages not meeting vacuum standards

▪ Data Logging: Comprehensive records for quality control and traceability

|

⚙ Applications

|

▪ Food Industry: Ensuring the shelf-life and safety of vacuum-packed food products.

▪ Pharmaceuticals: Maintaining the sterility and efficacy of vacuum-sealed medical supplies.

▪ Electronics: Protecting sensitive components from moisture and contaminants.

▪ Cosmetics: Preserving the quality and consistency of vacuum-packaged cosmetic products.

|

|

|

⚙ Advantages

☑ Enhanced Quality Control: Immediate detection of vacuum inconsistencies ensures only compliant products reach the market.

☑ Operational Efficiency: Automated monitoring reduces the need for manual inspections, saving time and labor costs.

☑ Product Safety: By ensuring proper vacuum levels, the system helps prevent product spoilage and contamination.

☑ Regulatory Compliance: Maintains adherence to industry standards and regulations regarding packaging integrity.

⚙ Conclusion

Implementing our Automatic Vacuum Detection System is a proactive step towards ensuring product quality, safety, and customer satisfaction. Its advanced technology, ease of integration, and high-speed operation make it an indispensable asset for modern packaging lines.

For more information or to request a demonstration, please contact our sales team.