MIC 18-18-6 Beverage Packaging Machine (8000-10000 BPH)

Company Introduction

Jiangsu Mic Machinery is a globally recognized leader in the manufacturing of beverage packaging equipment, specializing in advanced filling and packaging solutions for the beverage industry. Our products, including the beverage packaging machine series, are designed to meet the highest industry standards, offering high-speed, precision, and reliability for a wide range of beverage production needs.

With years of expertise in the field, we are committed to delivering cutting-edge technology and robust machinery that enhance the efficiency, productivity, and quality of beverage production lines. Our automatic beverage filling machines and beverage packaging equipment are trusted by beverage manufacturers worldwide for their outstanding performance, cost-effectiveness, and ease of operation.

|

|

Bottle Washing Machine The Bottle Washing Machine effectively cleans bottles before filling, removing dirt, debris, and residues. It ensures hygienic conditions for bottling operations, improving product quality and operational efficiency in high-speed production lines. |

|

Cap Screwing Machine The Cap Screwing Machine efficiently places and tightens caps onto bottles during the bottling process. It ensures secure sealing, preventing leaks and contamination, and enhances productivity in high-speed packaging operations. |

|

|

|

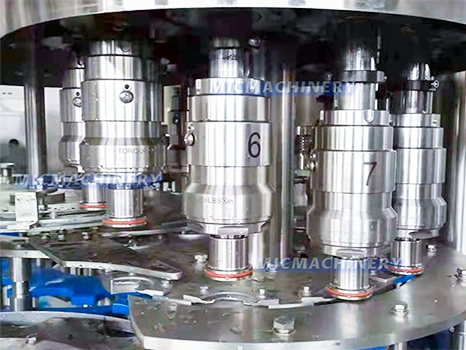

Filling System The Filling System is designed to accurately fill bottles with liquids, ensuring precise volume control and minimizing waste. It supports high-speed operations, improving efficiency and consistency in bottling lines. |

Working Principle of Beverage Filling Machine

The MIC 18-18-6 beverage packaging machine is designed to provide a fully automated filling process for a variety of beverages, including carbonated drinks, juices, and still beverages. Operating with 18 filling nozzles, the machine utilizes a rotary filling system, which allows for high-speed operation and precise filling.

The filling process begins with the bottles being fed onto a rotating platform, where they are automatically positioned under the filling nozzles. The system uses advanced sensors to control the filling volume and ensure that each bottle receives the exact amount of liquid. The automatic beverage filling machine is equipped with a pressure and vacuum system that ensures optimal filling for both carbonated and non-carbonated beverages, preventing the loss of carbonation in fizzy drinks.

As part of the beverage packaging equipment, the system incorporates an automatic cleaning function, ensuring that all parts of the machine are sanitized to meet the highest hygiene standards. The entire process is automated, minimizing human intervention and ensuring consistent filling and packaging of high-quality beverages.

Advantages of Beverage Filling Machine

The MIC 18-18-6 beverage packaging machine offers several key advantages that make it a valuable asset for beverage manufacturers:

1、High-Speed Performance

With 18 filling nozzles, this beverage packaging machine can fill up to 18,000 bottles per hour, making it ideal for large-scale production environments. Its high-speed operation significantly increases throughput and reduces production time.

2、Precise Filling Control

The advanced sensor-based control system ensures accurate filling, eliminating overfilling or underfilling, which reduces waste and ensures consistent product quality. This precision is especially important for maintaining the integrity of carbonated beverages.

3、Automated Operation

The automatic beverage filling machine features a fully automated system, reducing the need for manual labor and enhancing operational efficiency. The machine automatically adjusts for different bottle sizes and beverage types, ensuring smooth transitions between production runs.

4、Versatile and Adaptable

The beverage packaging equipment is compatible with various types of containers, including glass and PET bottles, and is highly adaptable to different beverage production requirements. This versatility ensures that manufacturers can easily adjust the system to meet changing production needs.

5、Cost-Efficiency

By reducing labor costs and minimizing product waste, the MIC 18-18-6 helps beverage manufacturers achieve significant cost savings. Its high-speed operation and low maintenance requirements further contribute to overall cost-effectiveness.

6、Enhanced Hygiene

The machine is equipped with an automatic cleaning system that ensures all parts are thoroughly sanitized, meeting the highest hygiene standards. This feature is critical for maintaining the quality and safety of food-grade beverages.

In conclusion, the MIC 18-18-6 beverage packaging machine offers a reliable, high-performance solution for beverage manufacturers looking to optimize their filling and packaging processes. Its combination of speed, precision, automation, and versatility makes it an indispensable tool for enhancing productivity and product quality.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |