MIC-BF Vial Labeling Machine (40-200 Bottles/min)

Introduction to Ampoule Labeling Machine Manufacturers

At Jiangsu Mic Machinery, we specialize in providing high-quality labeling solutions for a wide range of industries. As leading ampoule labeling machine manufacturers, we are committed to delivering precise, reliable, and efficient labeling solutions for businesses that require fast and accurate labeling of cylindrical containers. Whether you're labeling bottles, cans, or jars, our ampoule labeling machine is designed to meet the needs of industries such as food and beverage, pharmaceuticals, cosmetics, and more.

Our automatic vial labeling machine is built with advanced technology to ensure consistent and uniform label placement on bottles of all sizes. We understand the importance of branding and packaging quality, and our machines are engineered to help businesses enhance their production lines with minimal downtime and maximum efficiency.

|

Bottle straightening screw motor control, automatic adjustment of bottle distance and direction to ensure consistency. |

|

Label roller device beautiful and elegant, dust-proof, easy and convenient to change labels |

|

|

Stripping mechanism It can adjust the position of label removal, quickly adjust the position of label removal and delivery, and facilitate label replacement. |

|

Control the bottle to correspond one-to-one with the label, no label will be printed without a bottle, and no duplicate labels will be printed. |

|

|

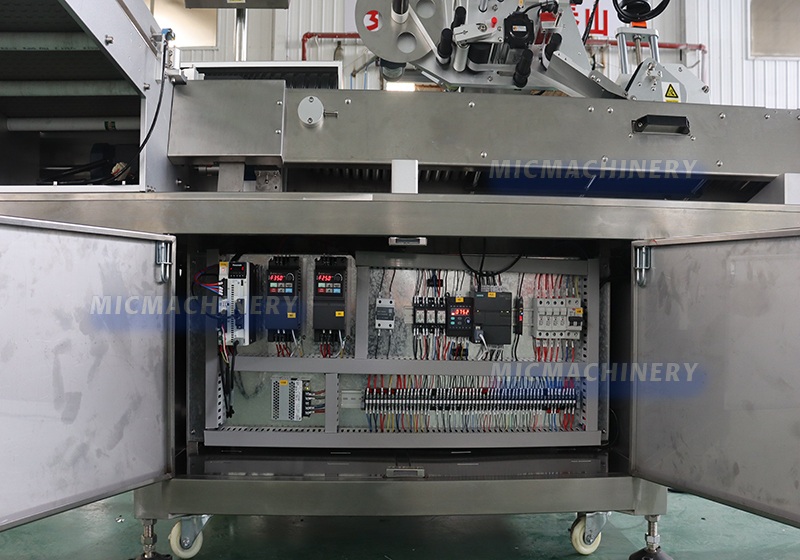

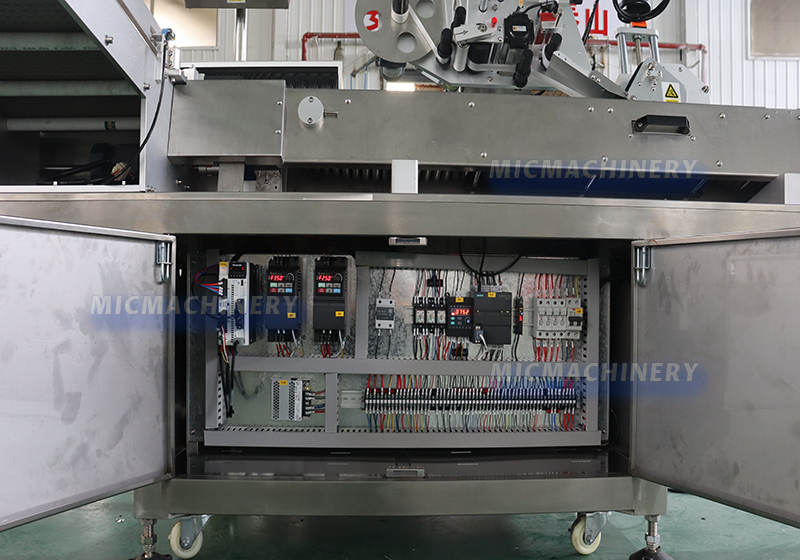

Electric control cabinet simple, convenient, and easy to learn. |

|

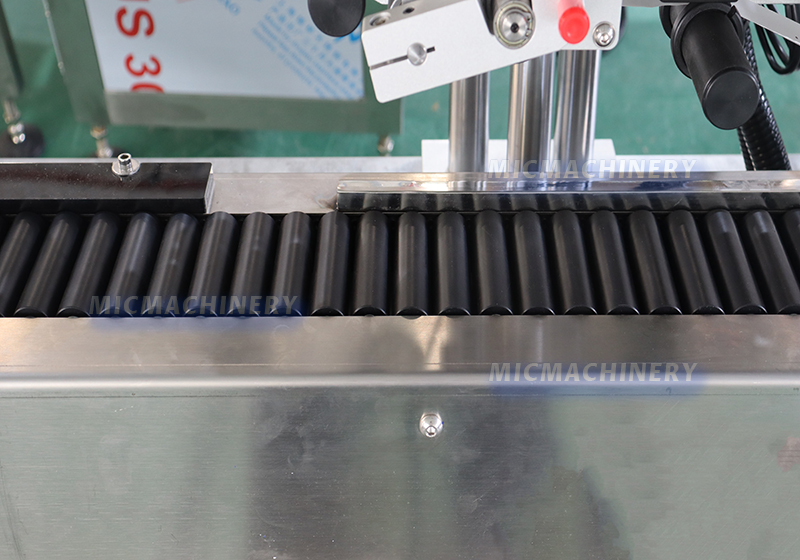

Transportation Imported brand, easy to clean, durable. |

|

|

|

Display screen sound and light alarm device, more convenient production supervision, emergency stop button, maximum protection of personnel safety. |

Description of the ampoule labeling machine

The ampoule labeling machine is designed to apply labels with precision on cylindrical containers, ensuring a professional and polished finish for every product. As vial labeling machine manufacturers, we take pride in offering machines that can accommodate a variety of bottle sizes and materials, including plastic, glass, and metal.

Our automatic vial labeling machine is equipped with advanced sensors and control systems, which help ensure that the labels are applied accurately and consistently, even at high speeds. Whether you're working with small cosmetic bottles or large beverage containers, our machines provide flexible labeling solutions to meet your specific production requirements.

Built for high-performance, the ampoule labeling machine minimizes manual labor and increases operational efficiency. With adjustable settings, it allows for easy modifications to accommodate various bottle sizes and different label formats. This versatility makes it an ideal solution for businesses with varying product lines or packaging styles.

As one of the leading vial labeling machine manufacturers, Jiangsu Mic Machinery focuses on providing durable, easy-to-operate, and cost-effective machines that integrate seamlessly into your production lines. Our machines are designed for long-term reliability, offering maximum uptime and low maintenance.

Choose Jiangsu Mic Machinery for your ampoule labeling machine needs, and benefit from our expertise in providing innovative and high-quality labeling solutions. With our advanced technology and user-friendly machines, you can enhance your labeling process, improve production speed, and maintain the highest standards of product presentation.

Workflow:

Manual placement of labeled products (connected or bottle sorting turntable) ->Automatic separation, correction, and transportation of products ->Product testing ->Product labeling ->Collection of labeled products (entering the next process) ->Removal of products.

Working principle:

After the bottle enters the labeling machine conveyor belt, it is fed to the labeling machine at a constant speed. The mechanical fixing device separates the labeled objects by a fixed distance and pushes them forward along the direction of the conveyor belt. Through the mechanical system (drive wheel, labeling wheel, scroll), the drive wheel intermittently drags the label tape to move, and the label is pulled out of the scroll and attached to the object being labeled through the labeling device.

Equipment advantages:

- Easy to adjust, with adjustable seats for front, back, left, right, up and down directions, plane inclination angle, and vertical plane inclination angle. Switching between different bottle shapes without dead corners meets GMP production requirements;

2. Automatic bottle sorting effectively eliminates the problem of unsmooth bottle sorting caused by bottle errors and improves stability;

3. It has automatic shutdown function, production counting function, power saving function (when there is no production within the set time, the equipment automatically switches to power-saving standby mode), production number setting prompt function, parameter setting protection function (parameter setting is managed by permission), which facilitates production management;

4. Powerful function, color touch screen control, optional Chinese and English operation interface, convenient and intuitive, powerful data memory function, can store 50 sets of labeling parameters, with production counting function, power saving function, production number setting prompt function, parameter setting protection function, convenient production management, one click switching between different product labels, no need for repeated debugging, simple and fast; And it has complete fault prompts and assistance functions;

5. High stability, using imported first-line brands for measuring targets and object sensors, with high detection sensitivity, stable performance, and durability; The stable and durable machine base and various components are designed with standardized modular design, ensuring complete interchangeability and 24-hour operation to ensure safety and stability.

6. Safety and hygiene, the chassis is made of stainless steel SUS304 material and T6 aluminum alloy, which will never rust and comply with GMP excellent manufacturing standards

Optional functions and components:

1、 Coding machine: Hot coding machine prints production date, expiration date, production batch number, etc. Synchronize coding and labeling to improve production efficiency.

2、 Spray coding machine: It can be matched with mainstream spray coding machines in the market to spray codes at designated positions on labels, perfectly combining with labeling machines.

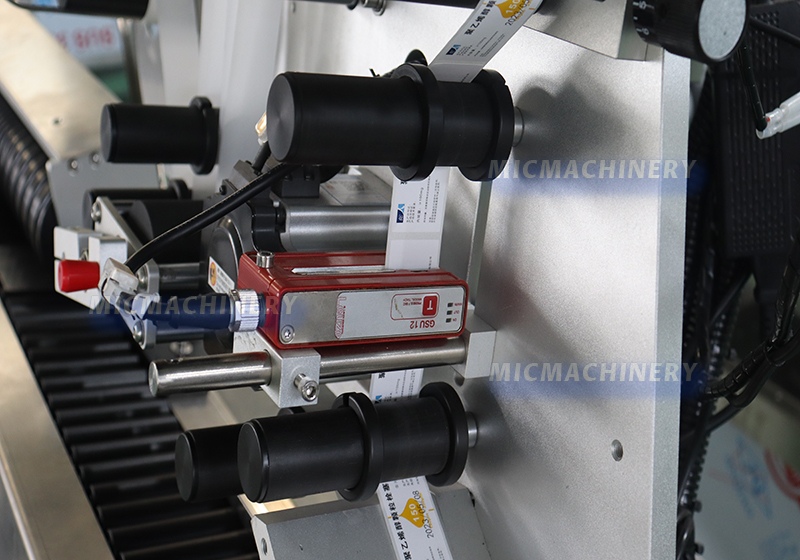

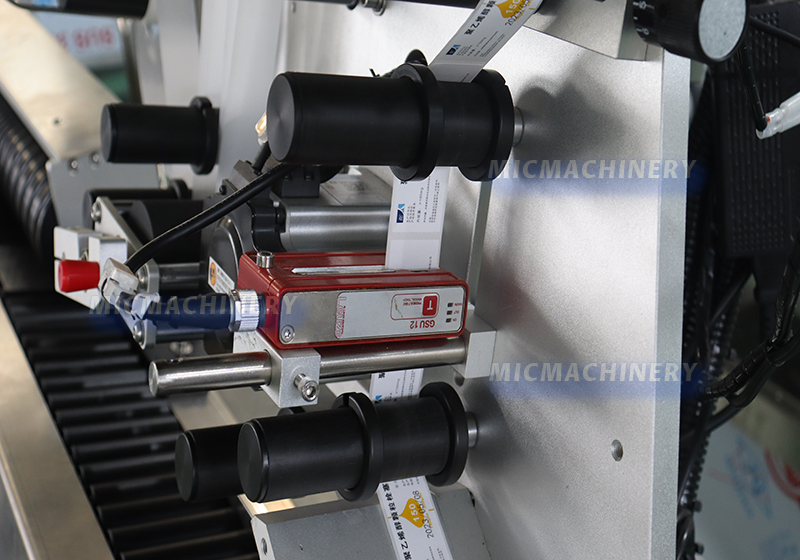

3、 Universal sensor: Ordinary sensors cannot detect transparent labels, and special electric eyes imported from Germany must be used in conjunction with them.

4、 Reader: Read QR codes, barcodes, and other information to facilitate the establishment of a product database for product traceability

|

Voltage specifications |

AC220V 50/60HZ |

|

Power consumption |

980W |

|

Labeling speed |

40-200 bottles/minute (speed adjustable, depending on object size and label length) |

|

Labeling accuracy |

+1mm (depending on product characteristics, softness, hardness, and roundness) |

|

Bottle diameter |

25-120mm |

|

Object Range |

Height 20mm~~300mm (can be customized according to customer requirements) |

|

Label specifications |

Height 10mm~~150mm, length 15~~300mm (special specifications can be customized) |

|

Inner diameter of paper roll |

Φ 76mm paper roll outer diameter: Φ 300 (maximum) |

|

Weight |

200KG |

|

Packaging size |

1950X1100X1300mm |

|

Belt width |

Customized according to the diameter of the sample bottle provided by the customer |

|

NO. |

Name |

Quantity |

Unit |

Brand |

|

1 |

Human Computer Interface (HIM) |

1 |

platform |

Kunlun Tongtai |

|

2 |

Programmable Logic Controller (PLC) |

1 |

platform |

Kunlun Tongtai |

|

3 |

Labeling motor |

1 |

platform |

Yankong |

|

4 |

Labeling motor driver |

1 |

platform |

Yankong |

|

5 |

Conveyor motor |

1 |

platform |

Shanghai Jianming |

|

6 |

Conveyor motor frequency converter |

1 |

platform |

Delta |

|

7 |

Bottle splitting motor |

1 |

platform |

JSCC |

|

8 |

Bottle separation motor controller |

1 |

platform |

JSCC |

|

9 |

Label motor |

1 |

platform |

JSCC |

|

10 |

Label motor controller |

1 |

platform |

JSCC |

|

11 |

Low voltage electrical apparatus |

1 |

set |

Schneider |

|

12 |

Label sensor |

1 |

set |

Laoyice Transparent Label Optoelectronics |

|

13 |

Labeling sensor |

1 |

set |

Omron |

|

14 |

Synchronous toothed belt |

1 |

set |

Bandong |

|

15 |

Pneumatic components |

1 |

set |

Airdac |

|

16 |

Conveyor belt |

1 |

set |

Shanghai Lilai |

|

17 |

frame |

1 |

set |

304 Stainless Steel |

|

18 |

system integration |

1 |

set |

Ruixiao |