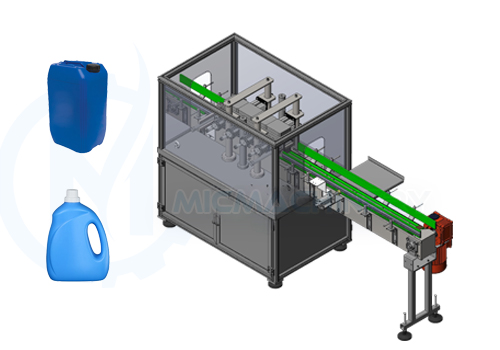

Vacuum Detection Machine

Design Basis

In the metal lid beverage packaging process, due to the impact of production equipment stability and operator skill levels, various packaging quality defects exist in the production line, leading to the creation of non-conforming products and impacting product quality. The specific issues include:

| No. | Quality Defect | Associated Risk | Description |

| 1 | Improper sealing | Material leakage | Sealing machine issue |

| 2 | Damaged lid | Material leakage | Lid issue |

Currently, most manufacturing companies rely on manual visual inspection to control these risks. However, manual inspection has significant limitations, such as the following drawbacks:

| No. | Drawback | Description |

| 1 | Fatigue, leading to unstable detection accuracy | Affected by line speed |

| 2 | Low precision, high uncertainty in manual checks | |

| 3 | Increasing labor costs |

As seen above, traditional manual inspection methods struggle to detect various quality defects in the production line effectively, making it difficult to control production risks.

Solution

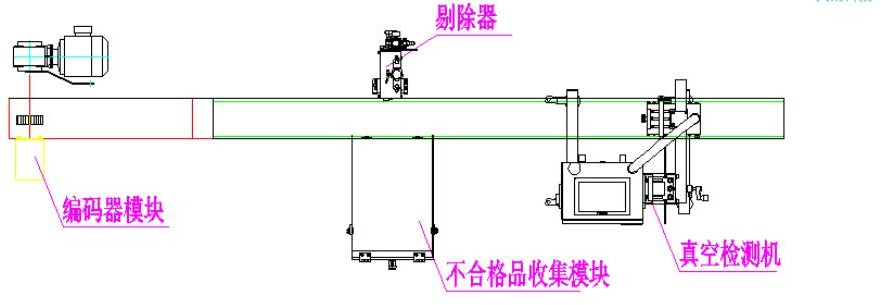

According to the beverage production process with metal lid packaging, automated inspection equipment can be installed at appropriate positions in the production line. This enables automatic online inspection for each can and automatically removes defective products. The key equipment list is as follows:

| No. | Installation Position | Installed Equipment |

| 1 | After secondary sterilization | Vacuum detection machine |

By installing automated inspection equipment, quality monitoring of each packaging step is achieved, and defective products are removed in real-time. In case of abnormal production faults, a comprehensive alarm system will notify on-site operators, ensuring timely troubleshooting and maintaining production efficiency.

Advantages of Installing Online Inspection Machines

| No. | Advantage | Description |

| 1 | High-speed, efficient | Effectively replaces large amounts of manual labor in high-speed production lines |

| 2 | High precision | Effectively solves the issue of low accuracy in manual checks |

| 3 | Reliability guarantee | Overall equipment operation is more reliable than manual work |

| 4 | Production data management | Collects and compiles production data, calculates product defect rates |

| 5 | Information management for packaging lines | Information-based management for later-stage product packaging |

These advantages go beyond just detection itself; advanced automation equipment should be a key part of future smart factories. For example, industrial Ethernet interfaces can be provided to upper layers, and multiple communication supports for other equipment, enabling future automation and networking upgrades.

Product Features

This machine can precisely detect and automatically reject defective cans. When the vacuum level inside the can differs, causing a deformation of the can lid, the machine detects the small deformation to determine if the vacuum level meets the required standard. Features include touch screen operation, simple to adjust, online data analysis, customizable data storage for different can types, automatic calibration, and synchronous rejection. It is widely used in beverage plants, canning factories, and other applications requiring precise online detection for two-piece aluminum cans, three-piece tin cans, glass bottles, and composite containers.

• Non-contact online detection

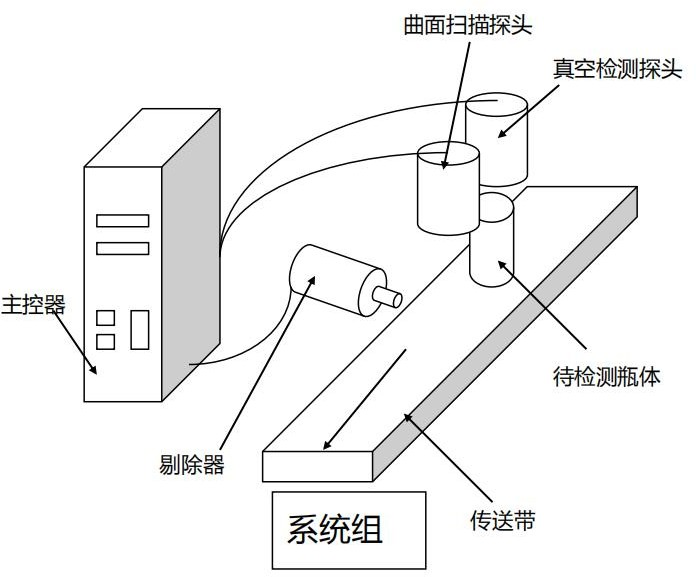

• Dual-head detection technology: electromagnetic pulse acoustic scanning and curved surface scanning

• Acoustic technology: Vacuum differences cause slight tension variations in the can surface, which can be accurately identified through audio signals generated by electromagnetic pulses.

• Curved surface detection: Complements acoustic detection to identify bulging cans and reverse cans.

• Applicable for vacuum level detection, bulging can detection, reverse can detection, etc.

• Suitable for conveyor speeds: 50 meters/minute

• Maximum speed: 300 cans/minute

• Weight: 50kg

• Automatic rejection of defective products

• Power: AC 220V/50HZ

• Air pressure: Compressor air source required at 0.3-0.8MPa

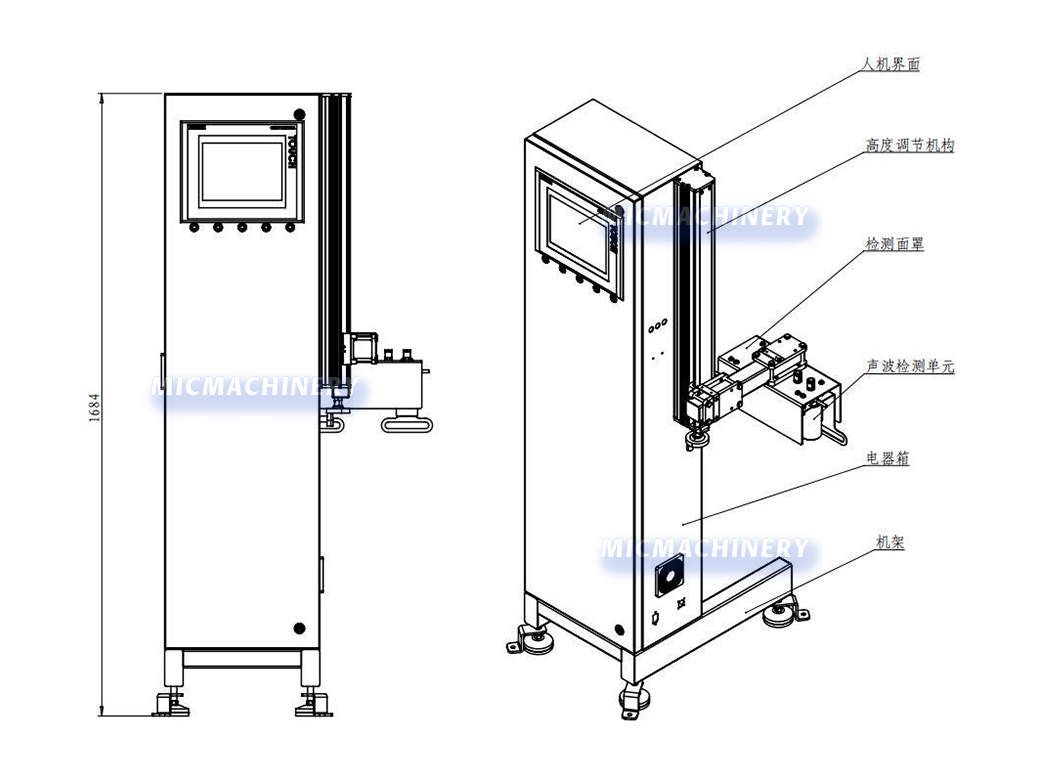

System Components

The detection system mainly consists of the human-machine interface, vacuum detection unit, and rejector. The vacuum detection unit includes the curved surface scanning probe and vacuum detection probe, which are the core components of the device. The human-machine interface consists of a touch screen, tower light, and operation interface. The rejector is the execution mechanism used to divert or reject defective cans.

Configuration Diagram:

| Feature | Specification |

| Applicable For | Vacuum detection, bulging can detection, reverse can detection, etc. |

| Conveyor Speed | 50 meters/min |

| Max Speed | 300 cans/min |

| Weight | 50 KG |

| Automatic Reject Function | Yes |

| Power Supply | AC 220V/50HZ |

| Air Pressure | Compressed air source requirement: 0.3-0.8 MPa |

| Name | Brand | Origin |

| PLC Controller | Siemens | Germany |

| Touch Screen | Xinje | China |

| Switch Power Supply | Mingwei | Taiwan |

| Solenoid Valve | AIRTAC | Taiwan |

| Cylinder | AIRTAC | Taiwan |

| Proximity Switch | Omron | Japan |

| Encoder | Omron | Japan |

| Analysis Software | Self-developed | China |