MIC-TG syringe labeller (400 units per minute)

Introduction to Our Syringe Labeller

At Jiangsu Mic Machinery, we provide high-performance labeling solutions for industries that require precise and efficient labeling of small and delicate products. Our syringe labeller is specifically designed for the accurate and fast application of labels to syringes, ensuring that each syringe is labeled with precision and consistency. This machine is ideal for use in the pharmaceutical, medical, and healthcare industries, where labeling accuracy and reliability are critical for safety, compliance, and quality control.

The syringe labeling machine is engineered with advanced technology to streamline the labeling process, offering high-speed operation without compromising on accuracy. Whether you're working with standard syringes or specialized medical products, our syringe label applicator ensures that your labeling process is efficient and reliable, helping you meet regulatory standards while increasing productivity.

|

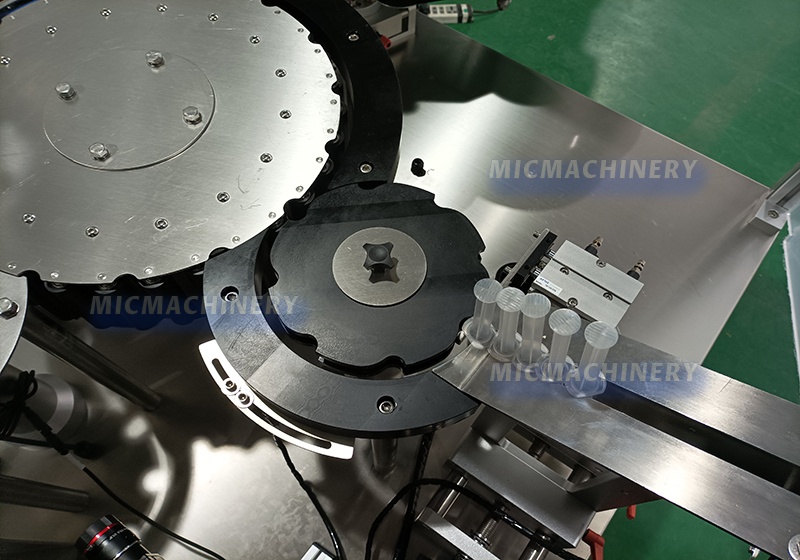

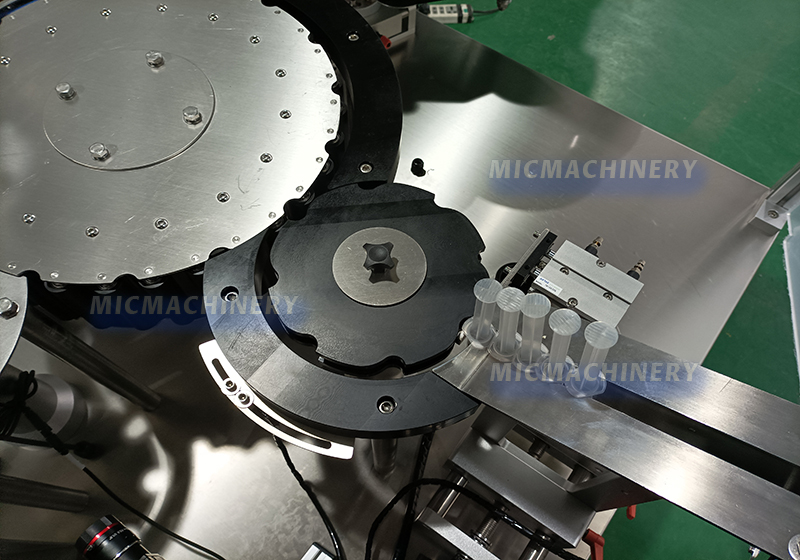

Feeding chute mechanism ① Needle tube buffering feeding increases resistance, effectively reduces the impact of needle tube transportation process, and prevents bottle breakage. ② Cutting mechanism, servo controlled lifting when changing specifications |

|

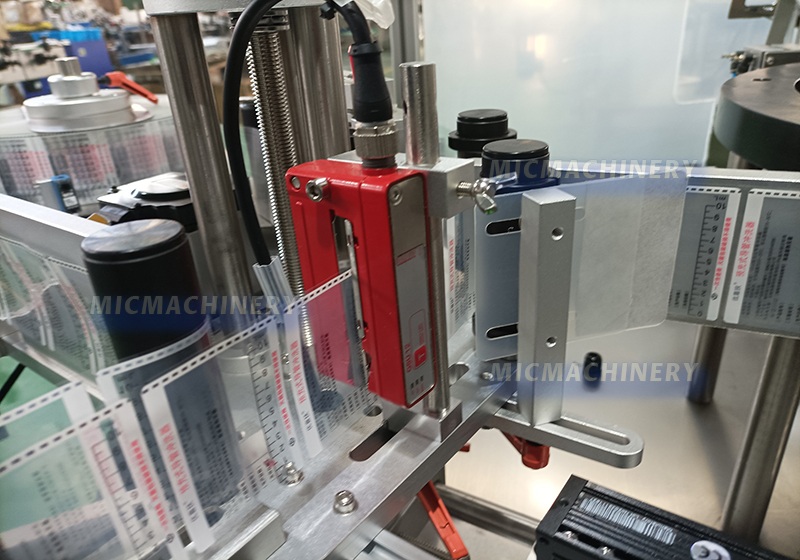

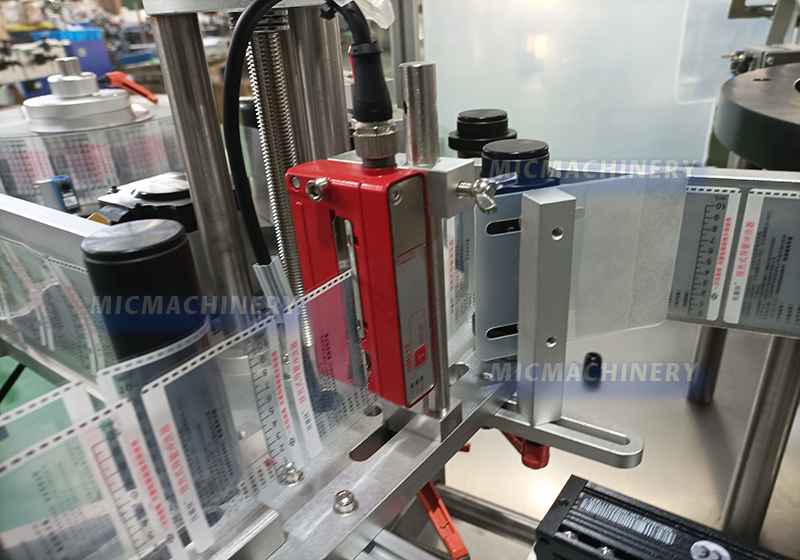

High precision groove shaped photoelectric high-precision low material electric eye detection, low material shutdown alarm |

|

|

Roll bottle labeling device Adopting a flexible bottle rolling device can effectively prevent excessive collision force between the bottle rolling mechanism and the syringe, which may damage the syringe |

|

Leakage labeling detection Labeling quality detection can also be flexibly selected through various methods such as fiber optics and cameras. |

|

|

Industrial control system 1: Using Taiwan Linghua or Yuhua industrial control computers, the equipment is operated and controlled, replacing traditional touch screen operations. It displays a large amount of information and can store an unlimited number of parameter groups. 2: It can conveniently monitor the operation status of equipment and facilitate data collection of machines by enterprises; 3: Due to the use of industrial control computers, it is possible to dynamically simulate the operation of equipment and intuitively reflect the operating status of the equipment |

Description of the Syringe Labeller

The syringe labeller is designed to apply labels to syringes with high precision, ensuring that each label is placed correctly and securely. The machine is equipped with advanced sensors and automated control systems to detect the syringe position and apply labels accurately. This makes it ideal for industries that require the labeling of small, cylindrical containers, such as syringes, vials, and other medical products.

Our syringe labeling machine is capable of handling various syringe sizes and label types, offering flexibility for businesses with different product lines. Whether you’re labeling standard syringes, insulin pens, or specialized medical devices, the machine ensures a perfect fit every time. The syringe label applicator offers consistent labeling results, reducing the risk of human error and improving efficiency in the production process.

The syringe labeling machine is easy to operate, with an intuitive interface that allows operators to set up and adjust settings for different syringe sizes and labeling formats. It also requires minimal maintenance, ensuring that the production line runs smoothly with minimal downtime.

Jiangsu Mic Machinery’s syringe labeller is built for durability and long-term performance. Whether you're labeling a small batch or running high-volume production, this machine provides the precision, reliability, and efficiency you need to streamline your labeling process.

Choose Jiangsu Mic Machinery for your syringe labeling machine needs and benefit from our advanced labeling solutions that improve productivity, enhance safety, and meet the strict labeling requirements of the pharmaceutical and medical industries. Let us help you optimize your production line with high-quality labeling technology.

Lift (up pole) section

① Using a hopper to place push rods, with a large storage capacity;

② Use a conveyor belt with a baffle to lift the push rod onto the discharge conveyor device, and then feed it into the feed channel of the screw labeling machine through the conveyor belt.

This method has a fast feeding speed, reaching up to 400 pieces per minute.

Needle bar feeding conveyor belt

① Anti loss O-belt type torsion bar conveyor clamping belt, clamping and feeding torsion bar material;

② For the torsion bar on the conveyor belt that has not been slotted, an electric dial is used to move the horizontal bar into the inflow channel.

Escaping part

Needle loading mechanism: The needle can be loaded manually onto the feeding conveyor belt or flexibly matched with front-end equipment.

(This structure has applied for patent protection)

Material retrieval institution:

① Using vacuum suction method to separate the nest plate from the nest box, vacuum detection sensor is used to prevent insufficient suction force from causing nest detachment and damage, and to protect the product.

② Using SMC rodless cylinder for precise positioning, place the extracted nest plate into the positioning conveyor

Servo feeding mechanism:

① The servo feeding mechanism pushes the product out of the honeycomb board;

② The gripper is made of flexible polymer material and the ejected needle tube is clamped by an SMC cylinder;

③ Adopting a servo electric cylinder rapid feeding device, the feeding speed can reach 500 pieces/minute.

| edition | Basic modules | Expansion module 1/needle sleeve | Expansion Module 2/Booster |

| Disposable syringe |

0.5-10 ml |

0.5-3 ml |

0.5-10 ml |

| Syringe diameter |

6-20 mm |

6-10,85 mm |

6-20 mm |

| Hourly output speed |

9000/14400/24000 |

24000 |

144000/24000 |

| Power Supply |

230/400V 50Hz 4,5KW |

230/400V 50Hz 4KW |

230/400V 50Hz 4KW |

| compressed air |

6 bar -12000l/h |

6 bar -26400/h |

6 bar -12000l/h |

| Machine weight |

800kg |

||

|

NO. |

Name |

Quantity |

Brand |

|

1 |

servo motor |

3 |

Yaskawa Electric (Japan) |

|

2 |

Servo drive |

3 |

Yaskawa Electric (Japan) |

|

3 |

transformer |

1 |

SMC Corporation (Japan) |

|

4 |

Cylinder with guide rod |

2 |

SMC Corporation (Japan) |

|

5 |

Magnetic switch |

2 |

SMC Corporation (Japan) |

|

6 |

Finger cylinder |

1 |

SMC Corporation (Japan) |

|

7 |

Rodless cylinder |

1 |

SMC Corporation (Japan) |

|

8 |

Magnetic switch |

2 |

SMC Corporation (Japan) |

|

9 |

Guide rod cylinder |

3 |

SMC Corporation (Japan) |

|

10 |

Magnetic switch |

2 |

SMC Corporation (Japan) |

|

11 |

Solenoid valve |

6 |

SMC Corporation (Japan) |

|

12 |

Editable program controller |

1 |

Siemens (Germany) |

|

13 |

Rotating isolation switch |

1 |

Siemens (Germany) |

|

14 |

Frequency converter |

1 |

Siemens (Germany) |

|

15 |

Circuit breaker |

1 |

Schneider Electric (France) |

|

16 |

Intermediate relay |

1 |

Omron Corporation (Japan) |

|

17 |

Photoelectric switch |

16 |

Keyence Corporation (Japan)/Optex/Omron/Sick AG (Germany) |

|

18 |

Three color police light |

1 |

法国Schneider |

|

19 |

Wiring terminals |

20 |

Utile |

|

20 |

touch screen |

1 |

Taiwan |

|

21 |

Contactor |

1 |

Schneider Electric (France) |

|

22 |

Conveyor belt motor 120w |

1 |

Jingyan |

|

23 |

Cam follower |

1 |

MISUMI |

|

24 |

Door handle |

8 |

|

|

25 |

Filter pressure reducing valve |

1 |

SMC Corporation (Japan) |

|

26 |

Pneumatic fittings |

1 |

SMC Corporation (Japan) |