MIC Small Fruit Juice Packaging Machine (20-40SPM)

Introduction to Jiangsu Mic Machinery

Jiangsu Mic Machinery is a leader in the design and manufacturing of high-performance packaging solutions for the food and beverage industries. With a proven track record of innovation and excellence, we provide state-of-the-art machines that optimize production efficiency and enhance product quality. Our product portfolio spans a wide range of packaging equipment, including advanced filling machines, labeling systems, and specialized solutions designed to meet the diverse needs of our global clientele. As a customer-focused company, we are committed to delivering machinery that combines cutting-edge technology with practical functionality, enabling businesses to boost productivity while reducing operational costs.

At Jiangsu Mic Machinery, we believe in helping our clients stay ahead of industry trends by providing them with automated, reliable, and sustainable solutions. Among our comprehensive range of products, the MIC Small fruit juice packaging machine (20-40BPM) stands out as an ideal solution for small to medium-scale juice producers. This machine is specifically designed to provide high-quality packaging while ensuring efficiency and cost-effectiveness for businesses looking to streamline their operations.

|

|

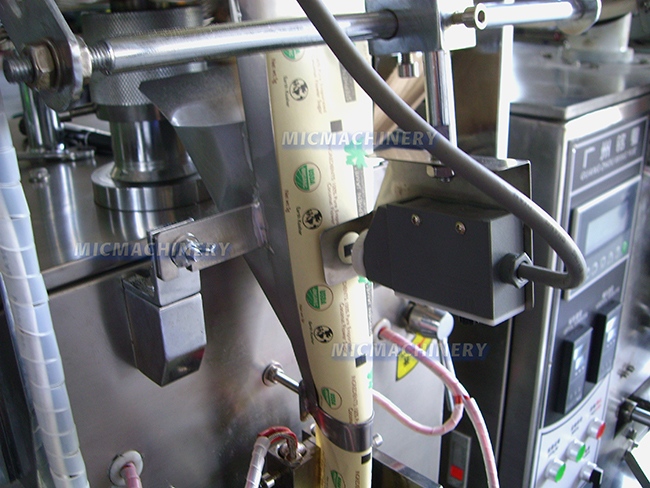

Bag Former A Bag Former is a machine used in packaging to shape and form bags from flat rollstock film. It ensures consistent bag formation, increases production speed, and maintains packaging quality in automated systems. |

|

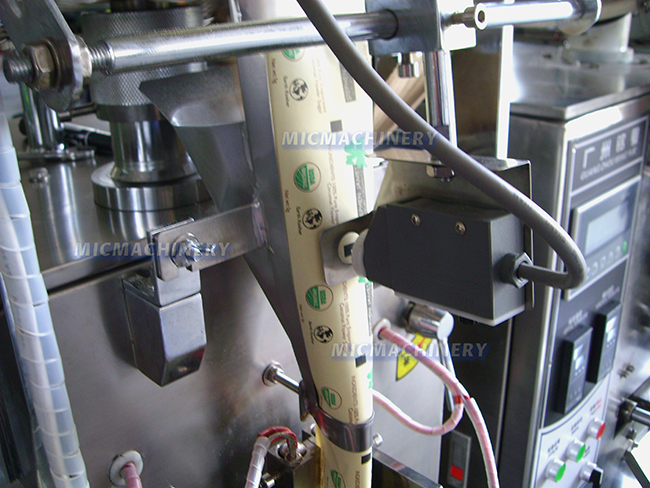

Sensor A Sensor is a device that detects and responds to changes in the environment, such as temperature, pressure, or motion. It provides real-time data, ensuring automation systems function accurately and efficiently. |

|

|

|

Control Panel A Control Panel is an interface used to monitor and manage the operation of machines or production lines. It provides real-time control, settings adjustments, and ensures smooth, efficient operation. |

Equipment Introduction: MIC Small Fruit Juice Packaging Machine (20-40BPM)

The MIC Small fruit juice packaging machine (20-40BPM) is a highly efficient, versatile solution designed for small-scale juice packaging operations. This juice pouch packing machine is ideal for businesses that need to package fruit juices at moderate speeds of 20 to 40 bottles per minute, making it perfect for producers with smaller production volumes or those just starting to scale their operations. Its compact and streamlined design makes it an excellent fit for production lines where space is limited, and the requirement for flexibility in packaging is essential.

Built with precision and reliability in mind, the small juice packing machine ensures consistent filling and sealing for a variety of juice products, including freshly squeezed juices, blends, concentrates, and other fruit-based beverages. The machine is capable of filling juice pouches with high accuracy, ensuring that each package contains the correct amount of liquid with minimal waste. This is achieved through the use of advanced filling technology that carefully controls the liquid flow, guaranteeing a precise volume is dispensed into each pouch.

The fruit juice packaging machine is equipped with an automatic pouch feeding and sealing system, which minimizes manual intervention and reduces the chances of human error. The system efficiently handles the entire process from pouch filling to sealing, providing an efficient and fully automated solution for small-scale juice production lines. Furthermore, the machine’s robust sealing mechanism ensures that each juice pouch is securely closed, maintaining freshness and preventing leaks during transportation and storage.

One of the key features of this juice pouch packing machine is its adaptability. It is capable of handling different types of pouches, including stand-up pouches, flat pouches, and spouted pouches, making it suitable for a wide range of packaging needs. Whether you’re packing small juice servings for retail or larger volumes for distribution, this machine offers flexibility in pouch size and material, allowing businesses to cater to various market demands.

In addition to its versatility, the small juice packing machine is designed with user-friendly controls and interfaces. The intuitive touch-screen control panel allows operators to easily adjust settings such as filling volume, speed, and temperature, ensuring optimal performance at all times. Operators can monitor the entire packing process in real-time, making it easier to detect and resolve any issues quickly, thus minimizing downtime and maintaining high production efficiency.

The machine’s hygienic design is another standout feature. Constructed from stainless steel and food-grade materials, the fruit juice packaging machine complies with international safety and hygiene standards, ensuring that the juice is packaged in a clean and safe environment. Additionally, the machine’s easy-to-clean design helps reduce maintenance time, keeping the production line running smoothly and efficiently.

Energy efficiency is also a key consideration in the design of the MIC Small fruit juice packaging machine (20-40BPM). The machine is engineered to operate with minimal power consumption, making it a cost-effective solution for businesses looking to reduce their energy costs while maintaining high levels of productivity.

Advantages of the MIC Small Fruit Juice Packaging Machine

1、High-Speed Performance

Despite being a small-scale machine, the small juice packing machine offers impressive speeds of 20-40 BPM, allowing businesses to meet moderate production demands without sacrificing efficiency.

2、Precision and Accuracy

The fruit juice packaging machine ensures precise filling, reducing waste and ensuring each pouch contains the correct amount of juice. This accuracy is crucial for maintaining product quality and meeting regulatory standards.

3、Versatility

This machine can handle a wide variety of pouch types, sizes, and juice formulations, making it adaptable to different product lines. Whether you’re packaging freshly squeezed juice, juice blends, or concentrates, it provides flexibility for different market needs.

4、Compact Design

With its small footprint, the juice pouch packing machine is perfect for businesses with limited space. Its compact design allows it to fit into smaller production areas while still offering high production efficiency.

5、Automatic Operation

The fully automated system minimizes the need for manual labor, reducing human error and improving production consistency. From pouch feeding to sealing, the entire process is automated for optimal efficiency.

6、Hygienic and Safe

Built with stainless steel and food-grade materials, the machine ensures the juice is packaged in a clean and hygienic environment. Its easy-to-clean design reduces downtime for maintenance and ensures long-term reliability.

7、Cost-Effective

The small juice packing machine is energy-efficient, reducing operational costs and making it an affordable option for small to medium-sized juice producers. Its low maintenance requirements and long service life further enhance its cost-effectiveness.

8、User-Friendly Interface

The intuitive control panel allows operators to easily adjust settings and monitor the packing process, ensuring smooth operation and minimizing production disruptions.

In conclusion, the MIC Small fruit juice packaging machine (20-40BPM) is an ideal solution for small to medium-scale juice producers looking for a reliable, efficient, and flexible packaging machine. With its precise filling system, hygienic design, and energy-efficient operation, it provides an excellent balance of performance and affordability, making it a valuable asset to any juice packaging operation.

| Capcity | 20- 40 bags/min | |

| Range of measurement | 1- 100 G | |

| Bag size | (L) 20-160 (W) 20-100mm | |

| Sealing Type | Back sealing | |

| Power | 1180W | |

| Total power | 380V/50HZ 220V/50-60HZ | |

| Packing material | Paper/the polyethylene,nylon/polyethylene,tea filter paper,etc | |

| Net weight | 2 60kg | |

| Overall dimensions | (L) 800*(W) 800*(H) 1800 | |

| Sensor | Changtong (China) |

| PLC Controller | Mitsubishi/J apan |

| Stepping motor | Jiangsu huanyu |

| Main Motor | Zhaoqing Zhongbao |

| Temperature control meter module | Yuyao families meter |

| Color code photoelectric | Zhejiang both |

| Intermediate relay | Zhejiang both |

| Solid state relay | Zhaoqing Zhongbao |

| Luck film motor | Jiangsu huanyu |

| Proximity switch | Jiangsu huanyu |

| Push button switch | Japan (OMRON) |

| Power switch | Japan (OMRON) |

| Color Printer for Date | China Nanyun |

| Machine Body | SS202 , Material Control Parts SS304 |