Semi Automatic Juice Pouch Packing Machine

Introduction to the Semi Automatic Juice Pouch Packing Machine

Jiangsu Mic Machinery’s Semi Automatic Juice Pouch Packing Machine is a high-performance, reliable solution tailored for efficient and precise juice packaging. Designed for businesses looking to enhance their production processes, this juice pouch packing machine provides an ideal way to package fruit juices and other liquid beverages in a variety of pouch sizes. Its advanced technology ensures high packaging standards, making it suitable for both small and medium-scale production lines.

This fruit juice packing machine stands out for its flexibility, enabling manufacturers to package a wide range of juice products, including natural fruit juices, nectar, and smoothies. The machine features a simple yet effective design, offering ease of operation, minimal maintenance, and a reliable sealing system to ensure that each pouch is securely sealed, preserving the freshness and integrity of the juice inside.

The juice packaging machine integrates a precise filling mechanism, ensuring the correct volume of juice is dispensed into each pouch, reducing wastage and improving operational efficiency. Its durable construction guarantees long-lasting performance, making it a valuable asset for any beverage producer.

|

|

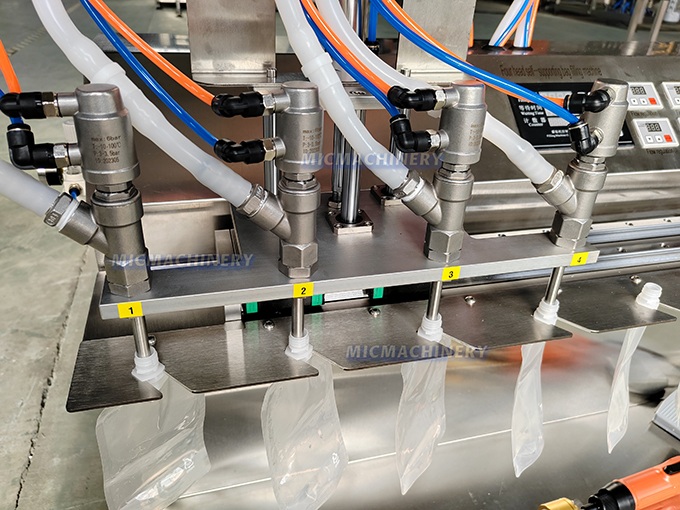

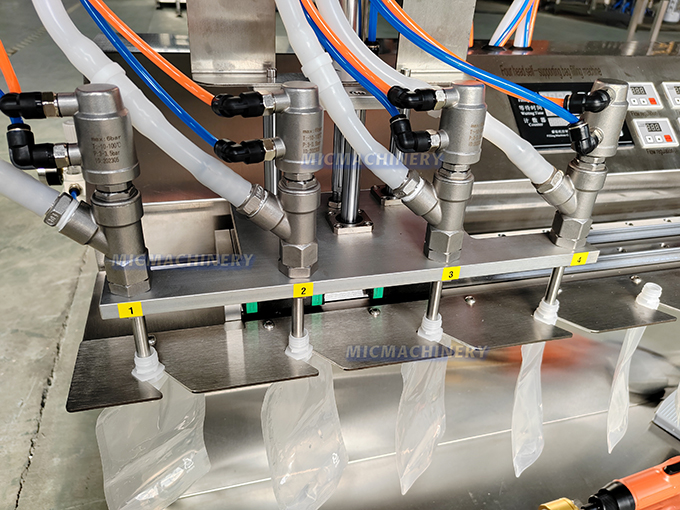

Filling tube A Filling Tube is a critical component in liquid filling machines, directing the flow of liquids into containers. It ensures smooth, accurate filling, preventing spills and optimizing production efficiency. |

|

Touch screen panel A Touch Screen Panel is an intuitive interface used to control and monitor machinery. It allows users to easily adjust settings, access real-time data, and streamline operations with a simple touch interface. |

|

|

|

Filling heads Filling Heads are essential components in automated filling systems, designed to precisely dispense liquids or powders into containers. They ensure accurate volume control, enhance efficiency, and reduce product waste.

|

Workflow and Advantages of the Juice Packaging Machine

The workflow of the Semi Automatic Juice Pouch Packing Machine is designed for both simplicity and efficiency. The process starts when an empty pouch is placed into position. The machine automatically fills the pouch with a precise amount of juice, eliminating the risk of overfilling or underfilling. After filling, the machine uses its advanced sealing system to securely close the pouch, ensuring an airtight seal that prevents leakage and preserves the quality of the juice for an extended shelf life. Finally, the packed pouch is ready for handling or distribution.

Several advantages make this juice pouch packing machine a must-have for businesses in the juice industry:

1、Flexibility in Packaging

The fruit juice packing machine is designed to handle different pouch sizes and liquid types, making it suitable for a wide range of juice products. This flexibility allows manufacturers to adapt to changing market demands or expand their product line without needing to invest in new equipment.

2、Efficiency and Cost-Effectiveness

The semi-automatic operation allows for reduced labor costs while maintaining high efficiency. The juice packaging machine operates quickly with minimal operator intervention, which increases overall productivity without compromising quality.

3、Precision and Accuracy

The machine’s filling system ensures that every pouch is filled with the correct volume of juice, reducing waste and maintaining product consistency. This precision helps manufacturers keep production costs low while ensuring high-quality packaging.

4、Durability and Reliability

Built with high-quality materials and engineered for long-lasting performance, the juice pouch packing machine is designed to withstand the demands of continuous operation. Its robust construction ensures minimal downtime and maintenance, improving overall operational efficiency.

5、User-Friendly Design

The machine is easy to operate, with a simple interface that allows operators to adjust settings quickly and efficiently. This user-friendly design reduces training time and helps maintain smooth operations.

By investing in this semi-automatic solution, businesses can enhance their juice packaging capabilities, improve operational efficiency, and deliver high-quality products to their customers. The fruit juice packing machine from Jiangsu Mic Machinery is a cost-effective, flexible, and reliable choice for manufacturers seeking to streamline their production process while maintaining top-quality standards.

|

Filling heads |

6 filling heads |

|

Production speed |

90-100 pouches/min |

|

Suitable pouch |

Spout pouch, doypack |

|

Filling range |

50ml-250ml or 250ml-500ml |

|

Filling precision |

±1-2% |

|

Capping speed |

Match the speed of filling station |

|

Capping heads |

6 capping heads |

|

Voltage |

380V-50hz-3 Phase |

|

Power |

5kw |

|

Air pressure |

0.6Mpa-0.7Mpa |

|

Dimension |

3.5mx2.2m×2m |

|

Weight |

2000kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |