MIC Semi-Automatic Beverage Sealing Production Line (30CPM)

MIC Semi-Automatic Beverage Sealing Production Line

Company Introduction

Mic Machinery is a renowned manufacturer specializing in innovative packaging solutions for the beverage industry. With years of experience, MIC Machinery offers reliable equipment designed to optimize production efficiency. Our products support various beverage types and are trusted globally for their durability and performance. The beverage sealing production line we provide is tailored to meet the needs of small to medium-sized enterprises aiming for quality and consistency.

|

|

Machine This compact and modern beer canning machine features a sleek white design with a transparent viewing area and an intuitive control panel. Its clean and professional appearance suits breweries and beverage businesses, ensuring functionality with aesthetic appeal. |

|

Control Panel The control panel of our beer canning machine is designed for ease of use, offering intuitive controls. |

|

|

|

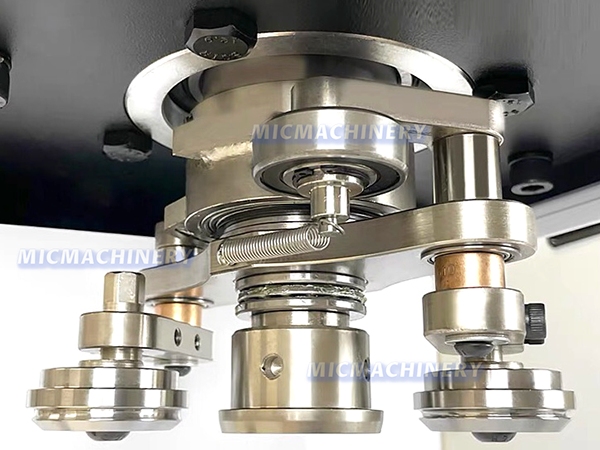

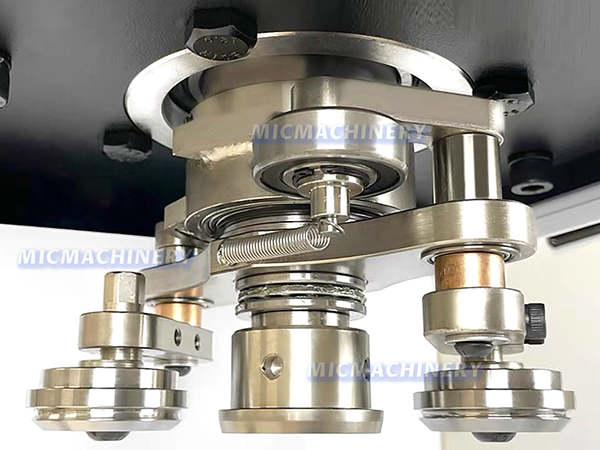

Capping Station A Capping Station is an essential part of the filling and packaging process, designed to securely apply caps to bottles, jars, or cans, ensuring product safety and preventing leaks or contamination. |

Working Principle

The MIC Semi-Automatic Carbonated Drink Sealing Line (30CPM) operates through a semi-automated process combining manual loading with automatic sealing. The key steps include:

1)Manual placement of pre-filled cans or bottles onto the sealing platform.

2)Precise positioning and clamping of the container to ensure stability.

3)Activation of the sealing head that applies controlled pressure and rotation to securely seal the lid, preserving carbonation.

4)Automatic release of the sealed container, ready for removal and the next cycle.

This process ensures consistent sealing quality within the beverage canning line, maintaining product freshness and safety.

Functions and Advantages

This sealing line is designed to enhance production within a beverage production line by providing:

▪ Efficient sealing at a speed of up to 30 cans per minute, suitable for small batches.

▪ Compatibility with various container types including aluminum cans and glass bottles.

▪ A compact and hygienic stainless steel frame for easy cleaning and durability.

▪ User-friendly controls that reduce operator fatigue and simplify training.

▪ Adjustable sealing parameters to handle different container specifications.

These features make the equipment ideal for producers seeking reliable performance without the complexity of full automation.

Application

The MIC Semi-Automatic Carbonated Drink Sealing Line is widely used in craft soda bottling, microbreweries, and pilot beverage lines. It fits perfectly into small-scale beverage sealing production line setups and serves as an effective component in modular beverage production line systems. Whether sealing cans or bottles, this machine ensures airtight closure essential for carbonation retention, making it valuable for startups and specialty beverage producers.

Conclusion

The MIC Semi-Automatic Carbonated Drink Sealing Line (30CPM) is a versatile, efficient solution for beverage manufacturers focusing on small to medium production scales. It integrates seamlessly into any beverage canning line or beverage sealing production line, delivering dependable sealing quality and supporting product freshness. Trust MIC Machinery to provide innovative equipment that boosts your production capabilities.

| Weight | 52kg |

| Voltage | 220V 50Hz |

| Packaging Type | CANS, Bottles |

| Dimension | 255*455*608mm |

| Motor power | 0.55KW |

| Filling speed | 30 cans each minute |