MIC 12-1 Beverage Production Line (1000-2000CPH)

MIC 12-1 Beverage Production Line

Machine is Suitable For

The MIC 12-1 Beverage Production Line is ideal for medium to large-scale beverage manufacturers looking to streamline their production processes. This versatile line is suitable for a wide variety of beverage types, including carbonated drinks, juices, iced tea, and flavored waters. Its flexibility makes it a perfect fit for businesses aiming to increase production capacity while maintaining high-quality standards. Whether you need a beverage canning line or a beverage filling line, this production line can be tailored to meet your specific needs, ensuring smooth operation and reliable output.

|

|

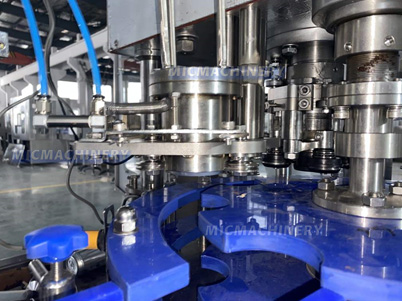

Can filling seaming machine foaming device |

|

Can filling seaming machine liquid tank A Can Filling Seaming Machine Liquid Tank is a storage component that holds the beverage (such as beer or soda) before it is filled into cans. Positioned above the filling station, the tank ensures a steady and consistent supply of liquid to the filling machine. It is designed to maintain the correct pressure and temperature to ensure accurate fills and prevent spillage. The liquid tank typically features precise control systems to regulate liquid levels and flow rates, ensuring smooth and efficient operation of the canning process. |

|

Working Principle

The MIC 12-1 Beverage Production Line operates with a fully automated system designed for high efficiency. The process begins with the arrival of empty bottles or cans, which are first cleaned and sanitized to ensure product hygiene. Once cleaned, the bottles are conveyed to the filling station where precise amounts of beverage are dispensed using advanced filling technology. This filling process is followed by the capping and labeling stages, all carried out automatically, reducing manual labor and improving production speed. The system integrates seamlessly, with each stage working in perfect synchronization to provide an efficient and reliable beverage production line.

Advantages

1.High Efficiency

The MIC 12-1 Beverage Production Line delivers exceptional performance with its high-speed filling, capping, and labeling processes. Designed for continuous operation, it supports large-scale production while ensuring minimal downtime.

2.Precise Filling

With advanced volumetric filling technology, this system ensures accurate and consistent beverage dispensing. This minimizes wastage and guarantees that each product meets the specified volume, which is crucial for maintaining product consistency.

3.Automation for Reduced Labor

The automated nature of the beverage production line reduces the need for manual intervention, increasing operational efficiency and reducing the risk of human error. This makes it ideal for businesses looking to optimize their labor costs.

4.Versatility and Flexibility

The line is compatible with various bottle sizes and beverage types, including carbonated and non-carbonated drinks. Whether you are using bottles or cans, the system is adaptable to a wide range of packaging options, making it a flexible solution for diverse production needs.

5.Durable and Reliable

The MIC 12-1 Beverage Production Line is built with high-quality materials, ensuring long-lasting durability and reliable performance even under continuous use. This is essential for businesses that rely on constant production.

6.User-Friendly Operation

Equipped with an intuitive control system, the production line is easy to operate and maintain. This ensures minimal downtime and allows operators to manage the entire process efficiently with minimal training.

7.Cost-Effective

By integrating filling, capping, and labeling into one streamlined system, the beverage canning line reduces the need for multiple standalone machines, cutting down on both capital investment and operational costs.

At Jiangsu Mic Machinery, we are committed to providing innovative and efficient solutions for the beverage industry. The MIC 12-1 Beverage Production Line exemplifies our dedication to offering reliable, high-quality equipment that helps businesses enhance production capacity, improve efficiency, and maintain product quality.

MIC 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |