Nitrogen Dosing Machine

Nitrogen Dosing Machine: Precision and Efficiency for Packaging

At Jiangsu Mic Machinery, we offer cutting-edge nitrogen dosing machines that are designed to meet the growing demands of industries requiring high-efficiency packaging solutions. Our high-precision nitrogen dosing technology is engineered to enhance product quality, extend shelf life, and ensure consistency in the packaging process.

|

|

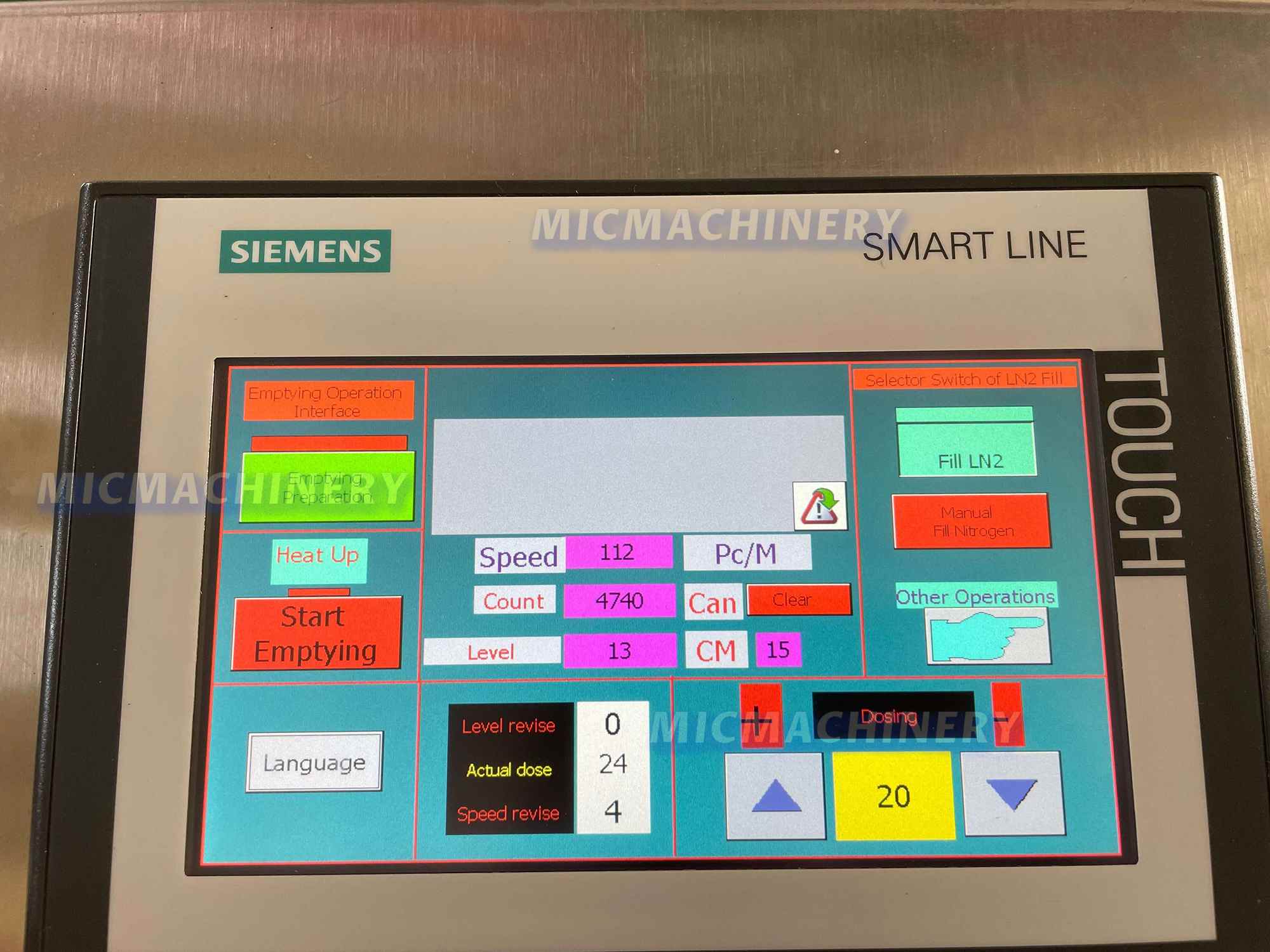

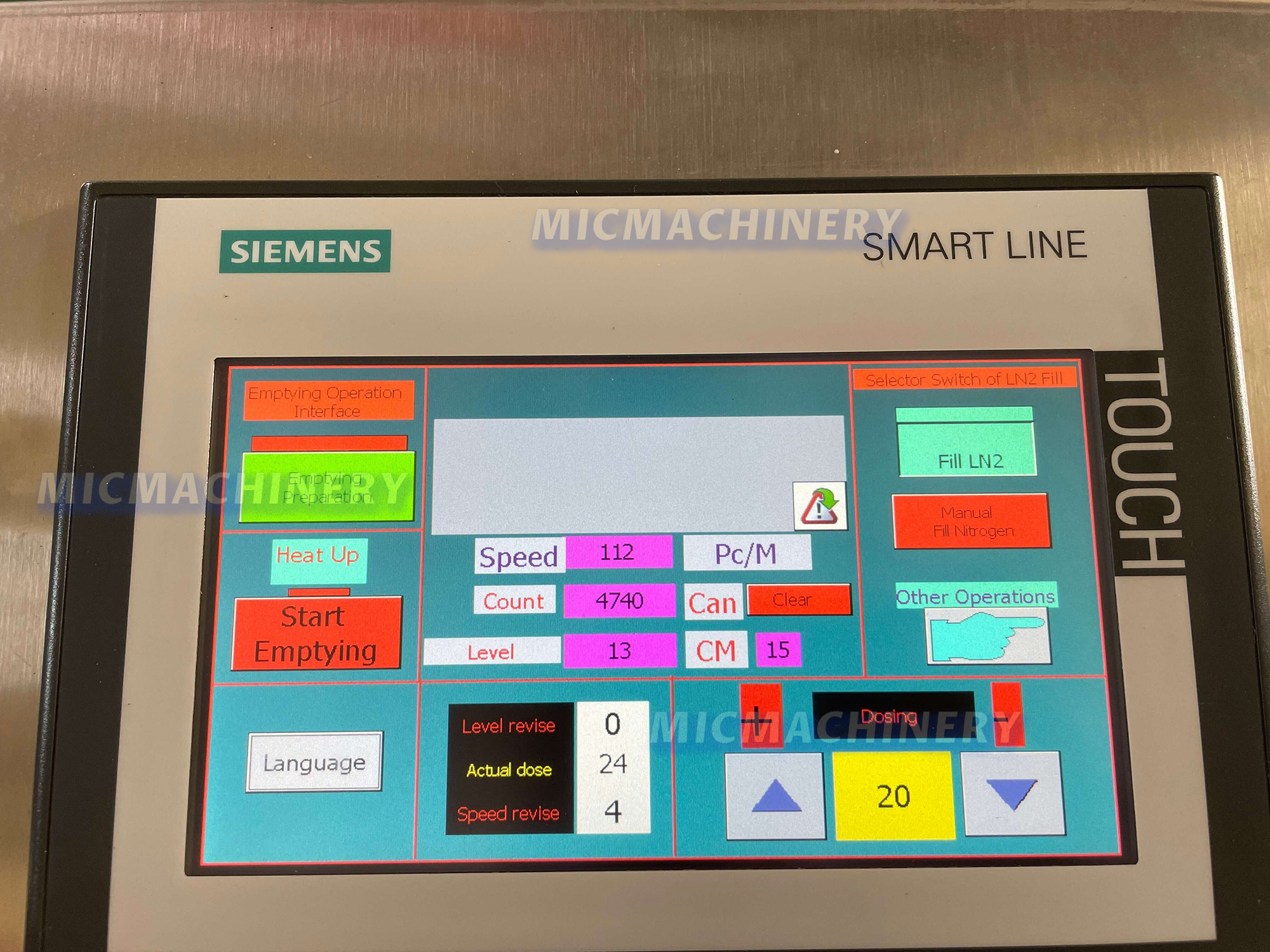

Control Panel The control panel is an essential component in modern industrial systems, providing users with intuitive, centralized control over machinery and processes. It allows for precise adjustments, real-time monitoring, and seamless integration with automated systems, ensuring optimal performance and efficient operation. |

|

Liquid Nitrogen Dosing Nozzle The Liquid Nitrogen Dosing Nozzle, integrated with the nitrogen dosing machine, ensures precise and controlled nitrogen infusion. Designed for accuracy, it helps optimize product preservation by preventing oxidation and maintaining freshness. Ideal for food, beverage, and pharmaceutical packaging processes. |

|

|

|

Pressure Regulator The Pressure Regulator, when paired with the nitrogen dosing machine, ensures stable and precise nitrogen infusion by controlling gas pressure. It helps maintain consistent flow and optimal dosing, preventing over-infusion or under-infusion, making it ideal for industries like food, beverage, and pharmaceuticals. |

Machine Information

The nitrogen dosing machine is an essential piece of equipment for industries like food, beverage, and pharmaceuticals, where precise nitrogen infusion is necessary. This machine ensures accurate nitrogen gas dosing into containers, preventing oxidation and preserving the freshness of the product. With advanced automation and easy-to-use controls, it provides consistent performance, reducing waste and increasing efficiency in production lines.

Main Components and Functions

The nitrogen dosing equipment consists of several key components: a high-precision nitrogen injector, a control panel, sensors, and a robust system for nitrogen supply. The high-precision injector ensures that nitrogen is dosed accurately, avoiding over or under-infusion. The system is equipped with intelligent sensors that monitor nitrogen levels in real-time, making automatic adjustments to maintain optimal conditions. Additionally, the control panel allows for seamless operation, enabling operators to adjust settings as needed for different production requirements.

This nitrogen dosing machine is designed for reliability and ease of maintenance. It is made with durable materials to withstand continuous use in industrial environments. Whether used for nitrogen flushing or preserving the quality of carbonated beverages, it offers a flexible and effective solution for a variety of packaging needs.

Conclusion

Jiangsu Mic Machinery's high-precision nitrogen dosing technology ensures that your packaging process runs smoothly, efficiently, and with optimal product quality. Our nitrogen dosing equipment helps industries meet the increasing demand for reliable, high-quality products while reducing operational costs. With advanced features, consistent performance, and professional support, our nitrogen dosing machine is the ideal choice for businesses looking to improve packaging processes and product preservation.

|

Technology Parameter

|

||||

|

Application

|

Beer, cold coffee, herbal tea, fruit juice, non-carbonated drinks and so on

|

|||

|

Package

|

Aluminum can, tin can, pet can, plastic bottle

|

|||

|

Production speed

|

30-300 cans/min, Set up continuous dosing speed

|

|||

|

Suitable size

|

180ml, 250ml, 330ml, 355ml, 500ml, 12oz, 16oz and so on

|

|||

|

Voltage

|

380V/50HZ/3Phase or 220V/50HZ/1Phase

|

|||

|

Weight

|

32kg

|

|||

|

Dimension

|

1300mm×750mm×450mm

|

|||

|

Main Configuration List

|

||||

|

PLC HMI

|

Siemens (Germany)

|

|||

|

Touch screen

|

Siemens (Germany)

|

|||

|

Solenoid valve

|

AirTAC (Taiwan, China)

|

|||

|

Proximity Switch

|

Omron (Japan)

|

|||

|

Temperature control

|

Omron (Japan)

|

|||

|

High speed dosing valve

|

MAC (USA)

|

|||

|

Dosing valve core

|

Germany

|

|||

|

Titanium filter stick

|

Germany

|

|||