MIC Small Juice Filling Line (20-40BPM)

MIC Small Juice Filling Line: Product Introduction

Machine is Suitable For

The MIC small juice filling line is designed for small to medium-scale juice production businesses looking for a compact, efficient solution for filling fruit juices. This machine is ideal for companies focusing on producing high-quality juices in smaller quantities, such as artisanal juice brands or local beverage producers. It is perfect for those seeking a fruit juice filling production line that balances affordability with high performance. Whether you're producing orange juice, apple juice, or mixed fruit beverages, the juice filling line is a versatile solution that meets your needs without sacrificing quality or speed.

Machine Features

The MIC small juice filling line offers numerous features that enhance its performance, efficiency, and ease of use. Here are some of the key features:

· Precise Filling Technology: Equipped with advanced filling technology, this juice filling line ensures accurate filling of fruit juices into containers, with minimal waste and a high level of consistency. This is especially important in maintaining product quality and improving production efficiency in small-scale operations.

· Flexible Bottle Handling: The fruit juice filling production line can handle a wide variety of bottle types and sizes, from small bottles to larger containers, making it adaptable for different production needs. Whether you're using PET, glass, or other types of containers, this machine is designed for flexibility and ease of use.

· Compact Design: The MIC small juice filling line is designed with a compact footprint, making it an excellent choice for facilities with limited space. Despite its smaller size, the machine offers high output, ensuring that even small-scale producers can achieve efficient juice production without compromising space.

· User-Friendly Interface: The machine comes equipped with an intuitive control system, allowing operators to easily monitor and adjust settings. The straightforward interface helps ensure smooth operation and reduces training time for new employees.

· Sanitary Construction: The entire juice production line is made from high-quality, food-grade materials that meet strict hygiene standards. This ensures that the juices produced are safe for consumption and comply with international health and safety regulations.

· Energy Efficiency: The MIC small juice filling line is designed to minimize energy consumption while maintaining peak performance, which can help businesses lower operational costs and reduce their environmental footprint.

Machine Introduction

The MIC small juice filling line is a reliable and efficient solution for small to medium-scale juice production. It is designed to simplify the filling process while maintaining the high standards of quality that Jiangsu Mic Machinery is known for. This juice filling line is perfect for businesses that need a reliable, cost-effective, and space-efficient machine to handle their juice production requirements.

The system operates seamlessly, handling everything from bottle cleaning and sterilization to filling and capping. The advanced technology used in the fruit juice filling production line ensures that the juice is accurately dispensed into containers, with a consistent fill level and minimal spillage. Additionally, the machine’s adaptability allows for easy switching between different fruit juices and bottle sizes, making it a versatile option for a variety of juice producers.

In conclusion, the MIC small juice filling line is an excellent choice for companies looking to enhance their juice production capabilities without the need for a large-scale system. With its combination of flexibility, efficiency, and high-quality construction, this machine is the ideal solution for businesses aiming to streamline their juice production line processes.

|

|

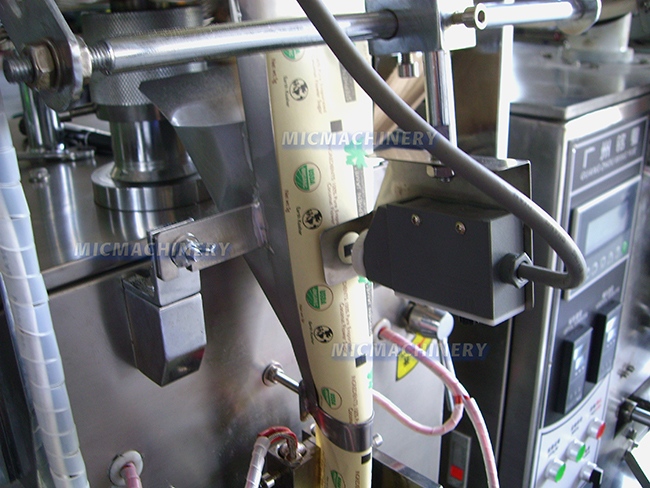

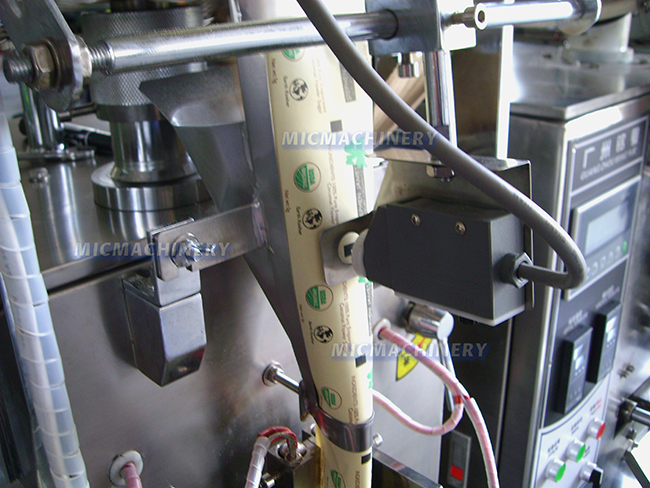

Bag Former A Bag Former is a machine used in packaging to shape and form bags from flat rollstock film. It ensures consistent bag formation, increases production speed, and maintains packaging quality in automated systems. |

|

Sensor A Sensor is a device that detects and responds to changes in the environment, such as temperature, pressure, or motion. It provides real-time data, ensuring automation systems function accurately and efficiently. |

|

|

|

Control Panel A Control Panel is an interface used to monitor and manage the operation of machines or production lines. It provides real-time control, settings adjustments, and ensures smooth, efficient operation. |

| Capcity | 20- 40 bags/min | |

| Range of measurement | 1- 100 G | |

| Bag size | (L) 20-160 (W) 20-100mm | |

| Sealing Type | Back sealing | |

| Power | 1180W | |

| Total power | 380V/50HZ 220V/50-60HZ | |

| Packing material | Paper/the polyethylene,nylon/polyethylene,tea filter paper,etc | |

| Net weight | 2 60kg | |

| Overall dimensions | (L) 800*(W) 800*(H) 1800 | |

| Sensor | Changtong (China) |

| PLC Controller | Mitsubishi/J apan |

| Stepping motor | Jiangsu huanyu |

| Main Motor | Zhaoqing Zhongbao |

| Temperature control meter module | Yuyao families meter |

| Color code photoelectric | Zhejiang both |

| Intermediate relay | Zhejiang both |

| Solid state relay | Zhaoqing Zhongbao |

| Luck film motor | Jiangsu huanyu |

| Proximity switch | Jiangsu huanyu |

| Push button switch | Japan (OMRON) |

| Power switch | Japan (OMRON) |

| Color Printer for Date | China Nanyun |

| Machine Body | SS202 , Material Control Parts SS304 |