MIC 12-1 Fruit Juice Production Line (1000-2000CPH)

MIC 12-1 Fruit Juice Production Line: Product Introduction

Machine is Suitable For

The MIC 12-1 fruit juice production line is ideal for high-volume production of a wide range of beverages, including fruit juices such as orange juice production line, apple juice, and other liquid products. This advanced juice filling line is designed for companies that need efficient and consistent filling, capping, and packaging systems to meet the demands of large-scale production.

|

|

Aluminum can sealing system The aluminum can sealing system ensures airtight, secure seals for beverage and food cans. Designed for precision and reliability, it enhances product freshness and prevents leaks during storage and transport. |

|

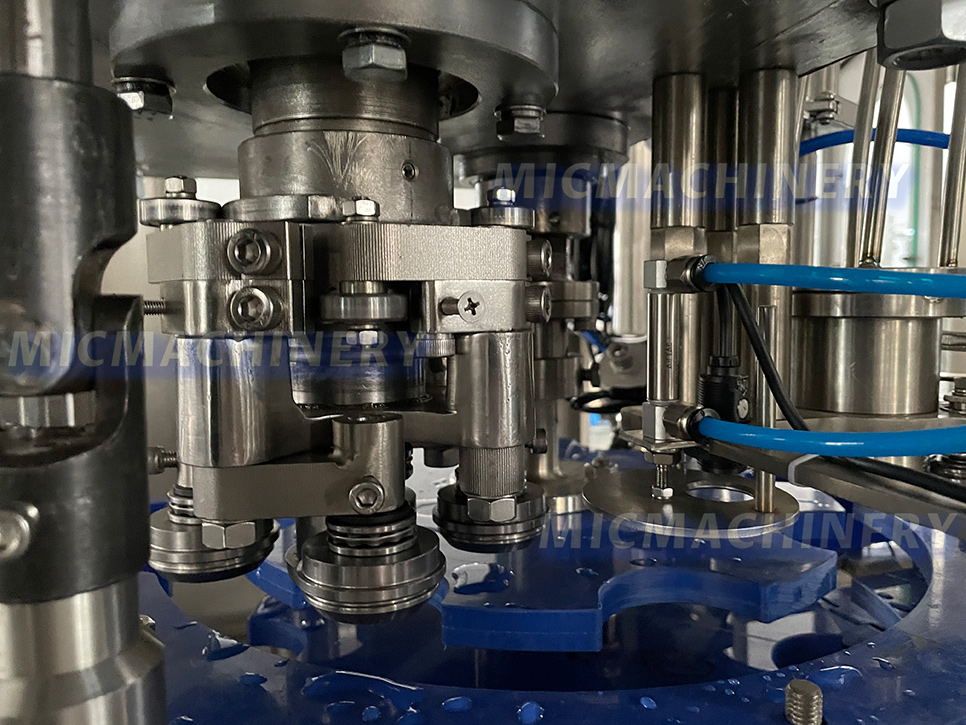

Gravity liquid filling system The gravity liquid filling system offers a reliable, efficient solution for accurately filling beverages and liquids. Ideal for various industries, it ensures smooth operation, precision, and minimal product wastage.

|

|

|

|

Liquid nitrogen dispenser The liquid nitrogen dispenser provides precise nitrogen dosing for food and beverage packaging. It enhances product shelf life, prevents oxidation, and ensures reliable, efficient packaging operations. |

Machine Features

· Fully Automated Operation: The MIC 12-1 fruit juice production line is designed to provide automated filling, capping, and packaging, reducing manual labor and ensuring higher efficiency and faster production speeds.

· High-Speed Performance: Capable of handling up to 12,000 bottles per hour, this line is perfect for high-demand production environments.

· Precision Filling: The system offers precise filling, ensuring minimal product waste and uniformity in each bottle. This feature is crucial for maintaining product consistency, especially in products like orange juice production line.

· Versatile Compatibility: While optimized for fruit juices, the line is highly adaptable, making it suitable for a wide range of beverages. Whether you're producing fruit juice production line or other drinks, it can handle various bottle sizes and materials, including PET, glass, and more.

· Energy Efficient: The machine's design focuses on energy conservation, reducing power consumption without compromising on performance or output quality.

· Hygienic Design: With a focus on food safety, the MIC 12-1 juice production line is built with high-quality materials and smooth surfaces, reducing the risk of contamination and ensuring that your beverages remain safe and clean.

Machine Introduction

The MIC 12-1 fruit juice production line is an all-in-one solution for fruit juice manufacturers who prioritize high efficiency and exceptional product quality. From the initial filling stage to the final packaging, this machine integrates cutting-edge technology to deliver a seamless production process.

The juice filling line features automatic control systems, ensuring that all aspects of the production process run smoothly. With the ability to handle multiple types of juice, including orange juice production line, this machine is designed to meet the diverse needs of the beverage industry. It provides a high level of flexibility while maintaining top-tier performance and minimal downtime.

Jiangsu Mic Machinery has designed this production line to deliver high-speed, automated solutions with minimal maintenance requirements, making it an invaluable addition to any juice production facility. Whether you're producing juice for large-scale commercial distribution or looking to expand your production capacity, the MIC 12-1 fruit juice production line ensures that your operations will run efficiently, reliably, and with consistent results.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | Cold filling, hot filling |

|

Can diameter range |

Ф40-90MM |

|

Can height |

92-168MM |

|

Dimension |

1800*1300*1950mm |

|

Weight |

1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |