MIC Aseptic Liquid Nitrogen Dosing Equipment

Aseptic Liquid Nitrogen Dosing Equipment: Precision and Sterility for High-Quality Packaging

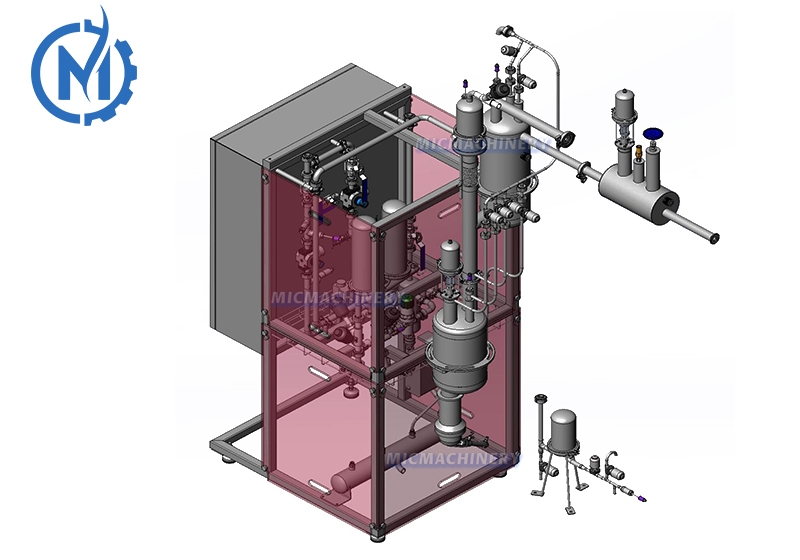

Jiangsu Mic Machinery introduces its state-of-the-art Aseptic nitrogen dosing equipment, designed to enhance product preservation and maintain sterility in high-demand industries such as food, beverage, and pharmaceuticals. This system ensures precise nitrogen infusion, helping to improve shelf life, maintain product integrity, and optimize packaging processes.

|

|

Liquid Nitrogen Storage And Dosing Chamber The liquid nitrogen storage and dosing chamber is a critical component of the Liquid Nitrogen Dosing Machine, ensuring precise nitrogen delivery for packaging applications. It maintains stable cryogenic conditions, preventing nitrogen loss while allowing controlled dosing. Designed for efficiency, it optimizes nitrogen dosing equipment performance and reliability. |

|

Piping Systems The piping system in a Liquid Nitrogen Dosing Machine ensures efficient and controlled nitrogen flow from storage to dosing nozzles. Designed for cryogenic conditions, it prevents leakage and maintains pressure stability. This system enhances the performance of nitrogen dosing equipment, ensuring precise and consistent automated nitrogen dosing. |

|

|

|

Valves Valves in a Liquid Nitrogen Dosing Machine regulate the precise flow of nitrogen, ensuring accurate dosing for packaging. Designed for cryogenic use, they maintain pressure stability and prevent leakage. These high-quality valves enhance the efficiency of nitrogen dosing equipment, supporting reliable and consistent automated nitrogen dosing.

|

Machine Information

Our Aseptic nitrogen dosing machine is built to deliver controlled and accurate dosing of liquid nitrogen into packaging. This process helps reduce oxygen levels, preventing oxidation and microbial growth while maintaining the sterility of the product. The machine is specifically designed for aseptic production environments, making it ideal for industries requiring stringent hygiene standards.

With advanced automated nitrogen dosing, the system ensures real-time monitoring and adjustment, minimizing nitrogen waste while maintaining dosing accuracy. The aseptic design prevents contamination, providing a clean and controlled nitrogen infusion process that meets industry regulations.

Main Components and Functions

The Aseptic nitrogen dosing equipment is equipped with high-precision dosing nozzles that regulate the flow of liquid nitrogen, ensuring even distribution across different packaging formats. Intelligent sensors track nitrogen levels, adjusting dosage based on real-time data to optimize efficiency.

The system features a user-friendly control panel that allows operators to easily configure parameters, such as nitrogen flow rate and dosing volume. With automated nitrogen dosing, the machine continuously adapts to production speed, ensuring seamless integration into high-speed filling lines.

Additionally, the nitrogen dosing machine is constructed with food-grade stainless steel and aseptic components, ensuring long-term durability and compliance with strict hygiene regulations. The machine’s self-cleaning function reduces maintenance efforts, minimizing downtime and improving overall productivity.

Conclusion

Jiangsu Mic Machinery’s Aseptic nitrogen dosing equipment is an essential solution for companies requiring sterile and precise nitrogen infusion. With automated nitrogen dosing technology and a high-performance nitrogen dosing machine, this system guarantees efficiency, consistency, and superior product preservation. Its advanced design meets the highest industry standards, making it an ideal choice for modern production lines focused on quality and safety.

| Liquid Nitrogen Usage Pressure | 2.5 – 3.0 bar |

| Working Pressure | min. 2 bar, max. 6 bar |

| Gaseous Nitrogen Usage Pressure | 4 bar, max. 8 bar |

| Working Pressure | min. 8.0 bar, max. 14.0 bar, 100 Nm³/h |

| Heating/Sterilization Steam | 20 kg/h, min. 2.5 bar, max. 10 bar, steam temperature 132-138°C (actual usage 2.0-2.4 bar) |

| Drying Nitrogen Gas | 50-100 cubic meters/hour, 6.0 bar |

| Production Liquid Nitrogen |

min. 25 kg/h (2/3 as liquid, 1/3 calculated as gas)

During continuous production, LIN supply pressure P = 1.5-2.0 bar, no bubbles, nitrogen supply pressure P = 6.0 bar.

|

| Electrical Control Cabinet Installation Power | 230V 50Hz, 16A/2KW |

| Liquid Nitrogen Consumption | min. 25 kg/hour |

| Heating and Sterilization Steam Consumption | 20 kg/hour |

| Drying Nitrogen Gas Consumption | 6 bar, 100 cbm/hour |

| Name | Origin |

| Liquid nitrogen vacuum tube | China |

| Secondary liquefaction tank main unit | China |

| Liquid nitrogen dosing head main unit | China |

| GEMÜ valve | Germany |

| Steam angle seat valve | Germany |

| Controller | Germany Siemens |

| Sensor | Japan Omron |

| Heat exchanger | China |

| High-speed dosing solenoid valve | USA MAC |

| Proportional control dosing head | Germany |

| Sterilizer | Germany |

| Cryogenic liquid nitrogen solenoid valve | Germany |

| Pressure sensor | Germany |

| Temperature sensor | Germany |

| Liquid level sensor | Germany |

| Electrical cabinet air conditioner | China |

| Titanium filter rod | Germany |