MIC 40-40-10 Water Filling Machine for Sale

MIC 40-40-10 Water Filling Machine for Sale – High-Efficiency Bottling Solution

About Jiangsu Mic Machinery

Jiangsu Mic Machinery is a leading manufacturer of advanced beverage and packaging solutions, specializing in high-performance filling equipment. Our commitment to innovation and quality has made us a trusted supplier for businesses worldwide. The MIC 40-40-10 Water Filling Machine is designed to meet the demands of modern water bottling operations, providing efficiency, precision, and reliability. For companies seeking a water filling machine for sale, we offer cutting-edge solutions tailored to production needs.

|

|

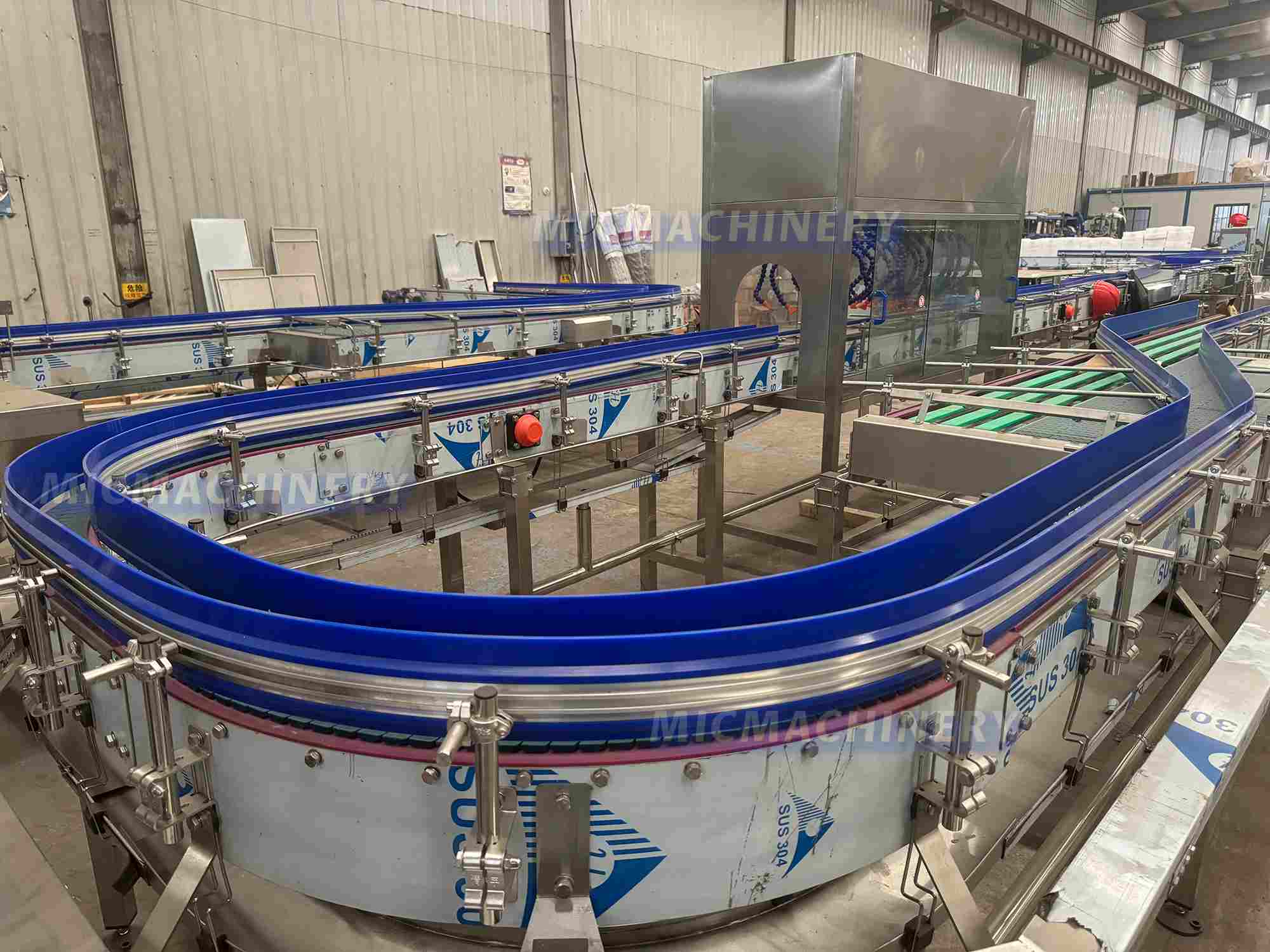

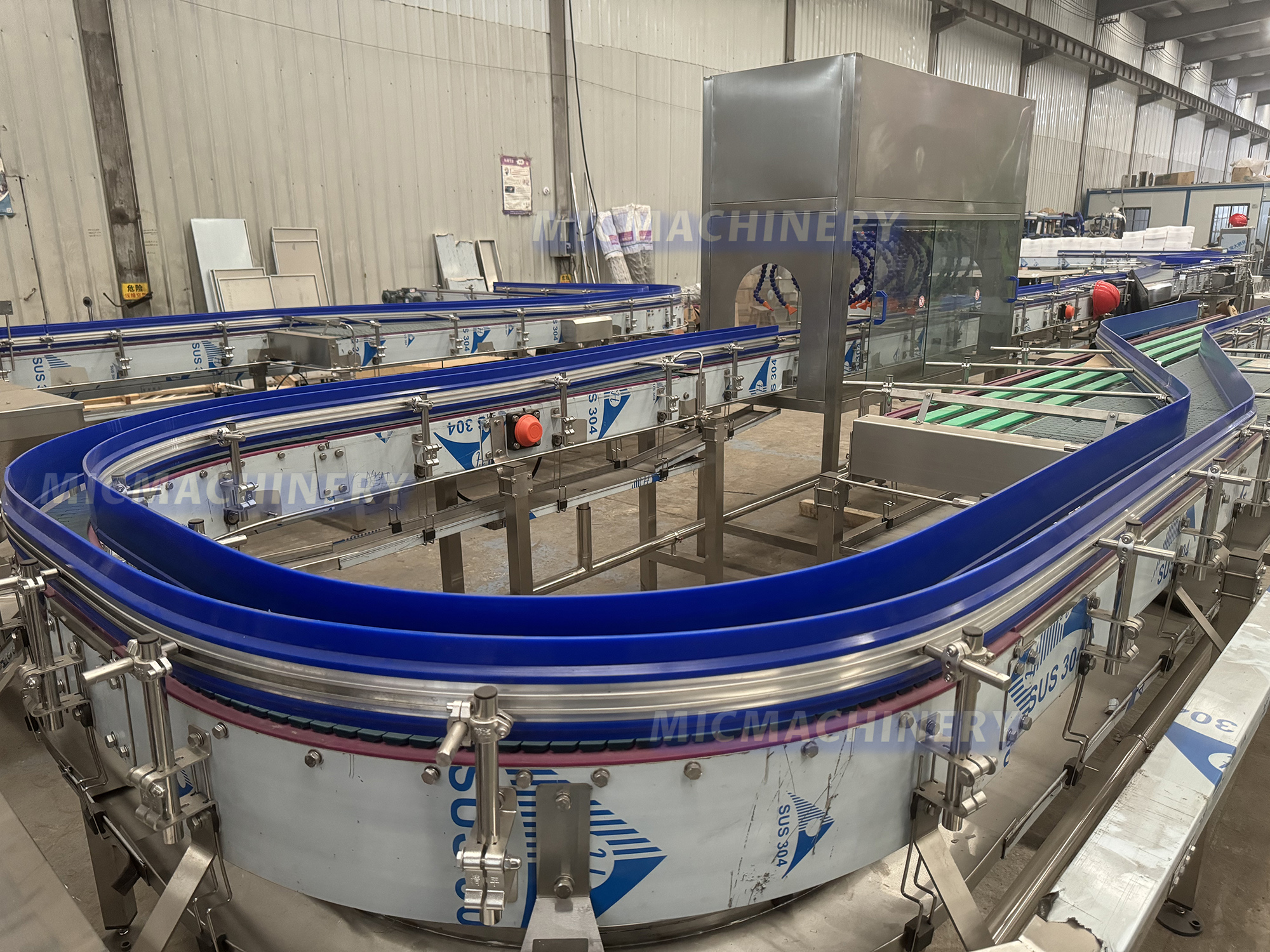

Conveyor System Optimize your water filling machine with a high-speed conveyor system for smooth and efficient bottle transportation. Designed for stability and durability, it ensures seamless movement through rinsing, filling, and capping stages. Ideal for packaged drinking water machine setups, it enhances automation and boosts production efficiency. |

|

Electrical Control Panel Optimize your water filling machine with a high-performance electrical control panel for precise automation and efficiency. Our advanced control systems ensure seamless operation, accurate filling, and energy savings. Designed for reliability, they enhance production stability in packaged drinking water machine setups. |

|

|

|

Filling Nozzles Enhance your water filling machine with high-precision filling nozzles for accurate, spill-free bottling. Designed for efficiency, our nozzles ensure smooth liquid flow, minimizing wastage and maximizing productivity. Ideal for packaged drinking water machine applications, they provide consistent and hygienic filling for various bottle sizes. |

Working Principle of MIC 40-40-10 Water Filling Machine

The MIC 40-40-10 Water Filling Machine operates through a fully automated process, integrating rinsing, filling, and capping functions into a single unit. Bottles are first cleaned using a high-speed rotary rinsing system, ensuring they are free from contaminants. The filling water machine utilizes advanced gravity filling technology, allowing precise liquid control to maintain consistency in every bottle. Finally, the capping system ensures secure and leak-proof sealing, preventing contamination and maintaining product integrity. This streamlined process enhances production efficiency, making it an ideal choice for packaged drinking water machine applications.

Advantages of the MIC 40-40-10 Water Filling Machine

1.High-Speed Production: Capable of filling up to 18,000 bottles per hour, maximizing efficiency for large-scale water bottling plants.

2.Advanced Automation: Fully automated operation reduces manual labor, ensuring consistent and hygienic filling processes.

3.Precise Filling System: Gravity-based technology provides accurate liquid levels, minimizing wastage and maintaining product uniformity.

4.Robust Construction: Made from high-grade stainless steel for durability, corrosion resistance, and compliance with food safety standards.

5.Versatile Bottle Compatibility: Supports various bottle sizes and shapes, offering flexibility for different production requirements.

6.Efficient Water and Energy Usage: Designed for sustainability, reducing water and power consumption without compromising performance.

For businesses looking for a reliable water filling machine for sale, the MIC 40-40-10 Water Filling Machine delivers exceptional performance and efficiency. Contact us today to learn more about our filling water machine solutions and how we can support your bottling production needs.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |