MIC 18-18-6 Automatic Water Packing Machine (5000-8000BPH)

MIC 18-18-6 Automatic Water Packing Machine (5000-8000BPH) – Product Introduction

Jiangsu Mic Machinery is proud to present the MIC 18-18-6 automatic water packing machine, designed for high-efficiency water bottling operations. With a production capacity of 5000-8000 bottles per hour, this machine is a top choice for large-scale bottling lines, ensuring consistency, speed, and high-quality standards for your products.

|

|

Bottle Washing Machine The Bottle Washing Machine effectively cleans bottles before filling, removing dirt, debris, and residues. It ensures hygienic conditions for bottling operations, improving product quality and operational efficiency in high-speed production lines. |

|

Cap Screwing Machine The Cap Screwing Machine efficiently places and tightens caps onto bottles during the bottling process. It ensures secure sealing, preventing leaks and contamination, and enhances productivity in high-speed packaging operations. |

|

|

|

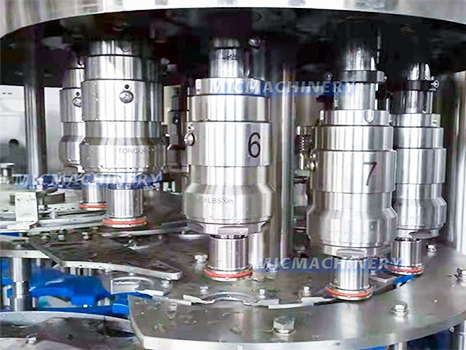

Filling System The Filling System is designed to accurately fill bottles with liquids, ensuring precise volume control and minimizing waste. It supports high-speed operations, improving efficiency and consistency in bottling lines. |

Machine Is Suitable For

The automatic water packing machine is specifically designed for use in the beverage and food industries, making it ideal for filling and packaging pure water, mineral water, and other water-based beverages. It caters to the needs of medium and large-scale production lines, where efficiency and high capacity are essential.

This water filling machine is compatible with various bottle sizes and materials, ensuring flexibility in packaging. Whether your production demands are for bottled water or other liquid-based products, the pure water filling machine delivers a reliable and seamless experience, meeting industry standards for hygiene and quality.

Working Principle

The automatic water packing machine utilizes advanced filling technology to ensure fast and accurate filling with minimal waste. The system operates in an automated sequence where bottles are first conveyed through the washing, filling, and capping stations. At each station, precise controls maintain high operational efficiency:

1)Bottle Washing: The machine uses a rinsing system to clean each bottle before filling, ensuring that all contaminants are removed and hygiene standards are met.

2)Filling Process: The pure water filling machine employs a gravity or volumetric filling mechanism to ensure that each bottle is filled with precision to the desired level. This ensures consistent quality in every bottle.

3)Capping: After filling, the bottles are automatically capped with high-speed capping heads that ensure a secure seal, preventing contamination and leakage.

Advantages

1、High-Speed Production

With a capacity of 5000-8000BPH, this water filling machine is perfect for large-scale production, ensuring your business can meet high-volume demands without compromising quality.

2、Energy-Efficient Operation

The machine is designed to optimize energy consumption, contributing to reduced operational costs and a more sustainable production process.

3、Precise Filling and High Consistency

The automatic water packing machine ensures that each bottle is filled accurately, maintaining product consistency across large batches.

4、Durable and Long-Lasting

Built from high-quality stainless steel and other durable materials, this machine is designed to withstand continuous operation in high-demand environments, making it a reliable investment for your production line.

5、Automated Process for Minimal Human Error

The automated control system significantly reduces the risk of human error, increasing the overall efficiency and reliability of the production process.

6、Easy Operation and Maintenance

With a user-friendly interface, operators can easily monitor and control the system, while the design allows for quick and easy maintenance, ensuring minimal downtime.

Conclusion

The MIC 18-18-6 automatic water packing machine offers a comprehensive solution for high-speed, high-efficiency water filling and packaging. As a trusted water filling machine manufacturer, Jiangsu Mic Machinery provides equipment that is both reliable and efficient, tailored to meet the needs of large-scale water bottling operations. This machine is an ideal choice for businesses looking to streamline their production lines, maintain high-quality standards, and increase overall production capacity.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |