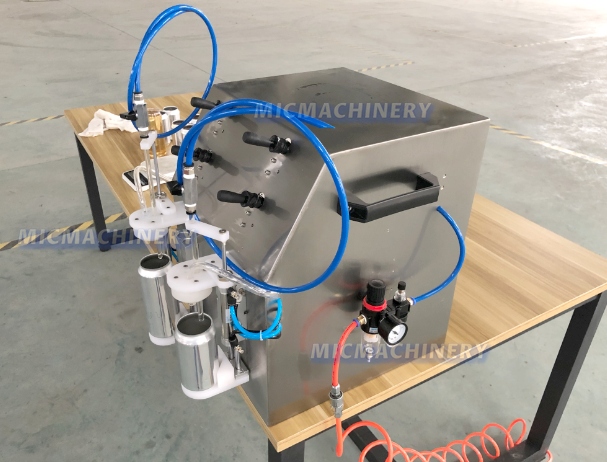

MIC Manual Cold Drink Packaging Machine (8CPM)

Machine is Suitable For

The MIC manual cold drink packaging machine is ideal for small to medium-scale beverage production operations. It is specifically designed for businesses looking to package cold drinks such as juices, flavored water, and soft drinks in a manual yet efficient way. This cold drink packaging machine is well-suited for startups, local manufacturers, and enterprises that require reliable, easy-to-use equipment without the need for complex automation. It provides an excellent solution for companies that wish to ensure high-quality filling while managing production volumes with greater flexibility.

|

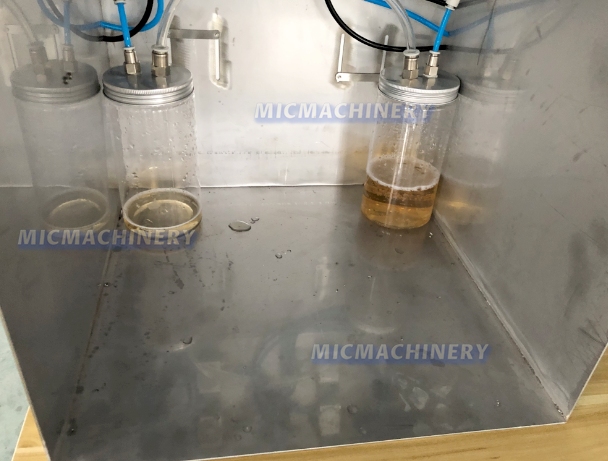

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can.

|

|

Control Button |

|

|

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Machine Features

Our drink packaging machine comes with several key features that make it a standout choice in the market. First, its precision filling technology ensures the exact quantity of liquid is dispensed into each bottle, minimizing spillage and waste. This is particularly important for businesses looking to optimize their resources while maintaining product consistency.

The machine also boasts a simple yet effective manual operation system. While it’s a manual machine, it offers high efficiency thanks to its ergonomic design, making it easy for operators to handle the filling process without fatigue. The drink filling machine also incorporates a strong sealing system that prevents leakage and ensures secure bottle closures.

The easy-to-adjust components allow the cold drink packaging machine to accommodate various bottle sizes, offering versatility for businesses with different product lines. This feature reduces the need for multiple machines or complicated configurations, allowing operators to seamlessly switch between different packaging formats.

Machine Introduction

The MIC manual cold drink packaging machine is a cost-effective solution for companies looking to streamline their beverage packaging process without the overhead costs of fully automated systems. Built with reliability in mind, this drink packaging machine ensures smooth and efficient operation with minimal maintenance required. The simple design allows for quick setup and teardown, making it perfect for businesses with fluctuating production schedules or smaller production lines.

The drink filling machine is constructed using high-quality materials that are durable and resistant to wear and tear, ensuring a long service life. Its compact size is another advantage, allowing businesses to optimize their workspace while maintaining high performance in production. Whether you're filling cold drinks in glass bottles, PET bottles, or other common packaging formats, the MIC manual cold drink packaging machine is designed to meet the diverse needs of the modern beverage industry.

| Filling Heads | 2 Pieces |

| Production Capacity |

8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand |

| Buttons | Schneider (France) |

| Touch screen | Siemens (Optional) |

| AC Contactor | Schneider (France) |

| PLC | Mitsubishi (Japan) / Siemens (Optional) |

| Frequency changer | Schneider (France) |

| Air cylinder | AirTAC (China) / FESTO (Optional) |

| Solenoid valve | AirTAC (China) / FESTO (Optional) |

| Relay | Autonics (Korea) / Omron (Optional) |

| Proximity switch | Autonics / Omron (Optional) |