MIC 12-1 Cold Drink Packing Machine (1000-2000CPH)

MIC 12-1 Cold Drink Packing Machine

Machine is Suitable For

The cold drink packing machine is specifically designed for the efficient packaging of cold beverages such as juices, flavored waters, carbonated drinks, and teas. This machine is ideal for medium to large-scale beverage production lines, offering versatility and high-performance capabilities for various types of beverage packaging. Its ability to accommodate different bottle sizes and materials, including PET and glass bottles, makes it suitable for a wide range of beverage manufacturers. Whether you're looking to pack juices for the retail market or carbonate beverages for larger production needs, the drink packaging machine is the perfect solution for businesses seeking reliable, high-speed performance in their packaging operations.

|

|

Can filling seaming machine foaming device |

|

Can filling seaming machine liquid tank A Can Filling Seaming Machine Liquid Tank is a storage component that holds the beverage (such as beer or soda) before it is filled into cans. Positioned above the filling station, the tank ensures a steady and consistent supply of liquid to the filling machine. It is designed to maintain the correct pressure and temperature to ensure accurate fills and prevent spillage. The liquid tank typically features precise control systems to regulate liquid levels and flow rates, ensuring smooth and efficient operation of the canning process. |

|

|

|

|

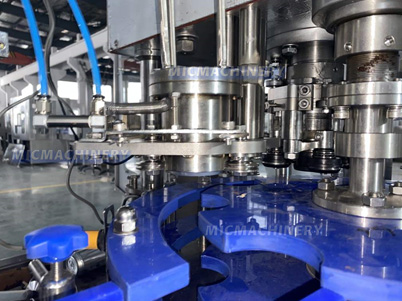

Working Principle of Drink Filling Machine

The MIC 12-1 cold drink packaging machine operates through an efficient filling process that ensures accurate filling while maintaining the quality and integrity of the drink. The process begins when bottles are placed onto a conveyor system. The cold drink packing machine uses advanced filling mechanisms, including pressure-filling and gravity-based technology, to fill each bottle with the precise amount of liquid. The drink packaging machine ensures that each bottle is filled to the desired level, minimizing spillage or overfill.

Once the filling is complete, the machine uses an automated capping system to seal each bottle securely, preserving the freshness and carbonation of the product. This process ensures a smooth, continuous operation that is ideal for high-volume production lines, reducing manual labor and enhancing overall efficiency.

Advantages of Drink Filling Machine

The MIC 12-1 cold drink packing machine offers several significant advantages, making it a highly recommended choice for beverage manufacturers:

1、High-Speed Production

With its efficient filling and capping systems, the cold drink packaging machine allows for fast, high-volume packaging, significantly increasing production output without compromising product quality.

2、Versatility in Packaging

The machine is capable of packaging various types of cold beverages and supports multiple bottle sizes and shapes. This makes it an adaptable solution for a range of beverage manufacturers looking to produce different products on the same line.

3、Precision and Accuracy

The drink packaging machine ensures precise filling, eliminating overfilling or underfilling, which reduces waste and enhances the consistency of each product batch.

4、Durable and Robust Construction

Built with high-quality materials, the machine ensures long-term reliability and is able to withstand the demands of high-volume, continuous production environments.

5、Energy Efficiency

Designed with energy-saving features, the cold drink packing machine helps reduce operational costs while delivering efficient performance.

6、Easy Operation and Maintenance

The machine’s user-friendly control panel makes it easy to operate, while the design ensures quick and easy maintenance, minimizing downtime and ensuring optimal performance over time.

In summary, the MIC 12-1 cold drink packing machine is a high-performance, reliable solution for beverage producers seeking to optimize their production process. With its advanced features, versatile packaging capabilities, and precision, it is an essential addition to any beverage packaging line.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |