MIC Manual Canning Machine Drinks (8CPM)

Introducing the MIC Manual Canning Machine Drinks (8CPM)

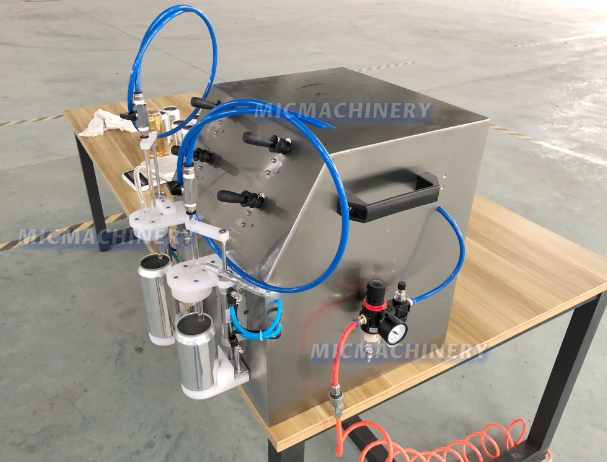

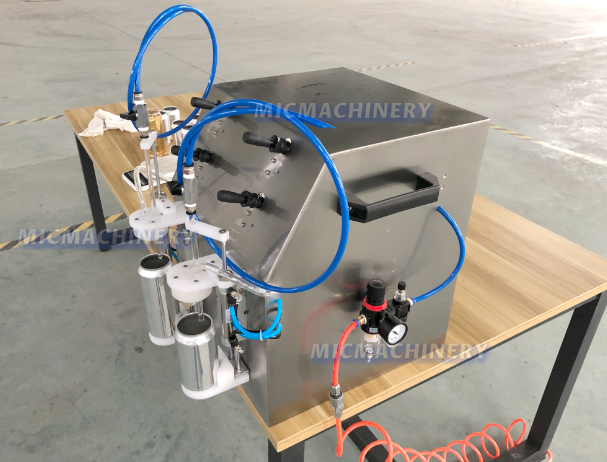

At Jiangsu Mic Machinery, we specialize in providing reliable and high-performance canning solutions for the beverage industry. Our MIC manual canning machine drinks (8CPM) is designed to offer small-scale beverage producers a simple, efficient, and affordable option for canning their products. Whether you’re a startup or a smaller operation, this machine offers versatility and ease of use. Below, we detail the features and advantages of the MIC manual drink canning machine.

|

|

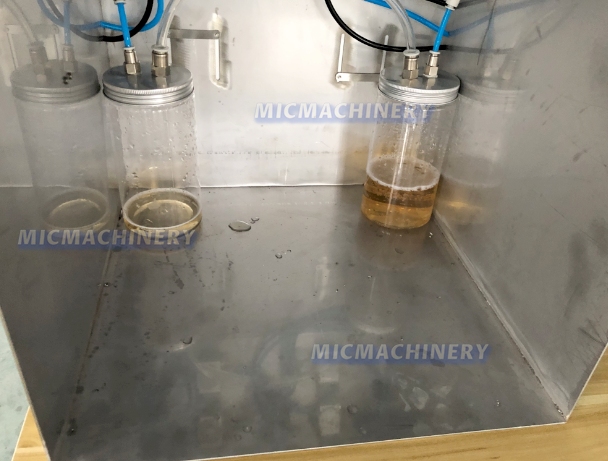

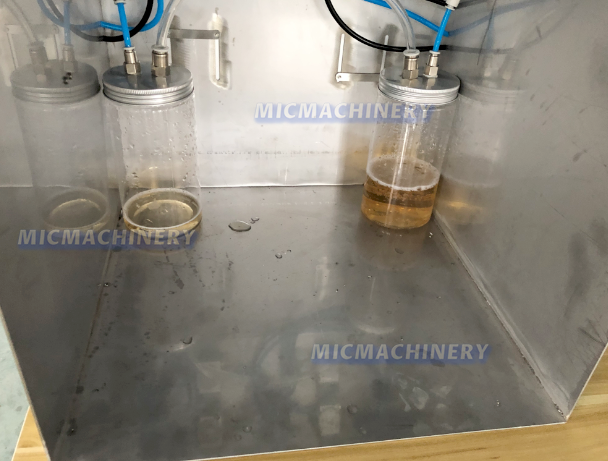

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can. |

|

Control Button |

|

|

|

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Company Introduction

At Jiangsu Mic Machinery, we have earned a strong reputation for delivering top-notch canning equipment for the beverage industry. With years of experience and a commitment to quality, we provide our customers with tailored solutions that meet their specific needs. Our MIC manual canning machine for drinks is no exception, offering a cost-effective solution for those with lower production volumes. Designed with simplicity and reliability in mind, this machine is the ideal choice for small businesses looking to streamline their canning process.

Working Principle of the Drink Canning Machine

The MIC manual canning machine drinks operates through a straightforward process, making it perfect for small-scale operations. The main steps involved include:

1)Manual Can Loading: Operators manually load empty cans onto the machine’s filling station.

2)Filling: The machine fills each can with the beverage using a gravity-fed filling system, ensuring uniformity.

3)Sealing: Once filled, the operator manually places the lid on the can and seals it securely, ensuring no leakage.

4)Manual Operation: The process is entirely manual, offering flexibility and control for each canning cycle.

This manual system makes it perfect for businesses that need a low-cost, simple solution without sacrificing efficiency.

Advantages of the Drink Canning Machine

The MIC manual canning machine for drinks provides several key benefits that make it a preferred choice for small-scale beverage producers:

1、Affordable and Efficient

This machine is an economical solution for small businesses, providing a reliable canning process at a low upfront cost. It’s ideal for producers who need to manage small production runs or offer seasonal drinks.

2、Simple Operation

With its manual design, this drink canning machine is easy to operate and requires minimal training. Operators can quickly learn how to load, fill, and seal cans efficiently.

3、Compact and Space-Saving

The MIC manual canning machine drinks is designed to fit into smaller production areas, making it ideal for facilities with limited space. Its compact size allows you to optimize the available space without sacrificing productivity.

4、Consistent Performance

Despite its manual operation, the machine delivers a high level of consistency in filling and sealing, ensuring that each can meets the desired quality standards.

5、Durability and Ease of Maintenance

Built from durable materials, this machine is designed for long-term use with minimal maintenance. It’s also easy to clean, ensuring it stays in optimal condition.

Conclusion

For small-scale beverage producers looking for an affordable and reliable canning solution, the MIC manual canning machine for drinks (8CPM) offers an excellent option. It combines simplicity with precision, providing an effective way to fill and seal cans at a low cost. At Jiangsu Mic Machinery, we are committed to delivering high-quality machinery that meets the specific needs of our customers.

If you’re looking to enhance your production process with a cost-effective, reliable drink canning machine, contact us today to learn more about the MIC manual machine and how it can benefit your business.

| Filling Heads | 2 Pieces |

| Production Capacity | 8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand | |

| Buttons | Schneider (France) | |

| Touch screen | Siemens (Optional) | |

| AC Contactor | Schneider (France) | |

| PLC | Mitsubishi (Japan) / Siemens (Optional) | |

| Frequency changer | Schneider (France) | |

| Air cylinder | AirTAC (China) / FESTO (Optional) | |

| Solenoid valve | AirTAC (China) / FESTO (Optional) | |

| Relay | Omron (Japan) / Schneider (France) | |

| photoelectric sensor | Autonics (Korea) / Omron (Optional) | |

| Proximity switch | Autonics / Omron (Optional) | |