MIC 12-1 Fully Automatic Drink Canning Machine (1000-2000CPH)

Introducing the MIC 12-1 Fully Automatic Drink Canning Machine (1000-2000CPH)

At Jiangsu Mic Machinery, we specialize in providing top-tier solutions for the beverage industry. Our MIC 12-1 Fully Automatic drink canning machine is designed to enhance production efficiency while maintaining high-quality standards. Capable of filling 1000 to 2000 cans per hour (CPH), this machine is ideal for medium to high-volume production lines. It is built to handle a wide range of beverages, offering optimal performance for carbonated drinks, juices, and more. Below, we outline the working principle and key advantages of this innovative drinks canning machine.

|

|

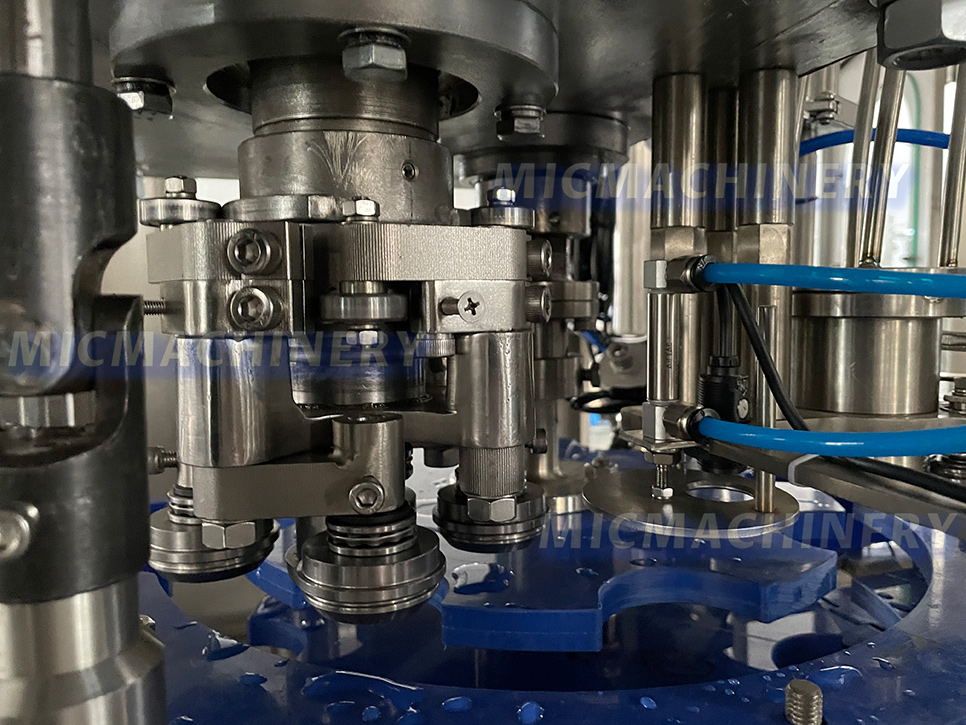

Aluminum can seaming system The aluminum can seaming system ensures airtight, secure seals for beverage and food cans. Designed for precision and reliability, it enhances product freshness and prevents leaks during storage and transport. |

|

Gravity liquid filling system The gravity liquid filling system offers a reliable, efficient solution for accurately filling beverages and liquids. Ideal for various industries, it ensures smooth operation, precision, and minimal product wastage.

|

|

|

|

Liquid nitrogen dispenser The liquid nitrogen dispenser provides precise nitrogen dosing for food and beverage packaging. It enhances product shelf life, prevents oxidation, and ensures reliable, efficient packaging operations. |

Working Principle of the Drink Canning Machine

The MIC 12-1 canning machine drinks utilizes advanced filling technology to ensure high-speed and precise canning operations. The machine operates with an automatic filling system that is both efficient and reliable.

Can Feeding and Orientation: The process begins with the automatic feeding of empty cans into the machine. These cans are carefully oriented to ensure proper alignment for the filling and sealing stages.

Filling Process: The drink canning machine employs a pressure filling system that accurately fills each can. The system adjusts to the viscosity and carbonation level of the beverage, ensuring that both carbonated and non-carbonated drinks are filled at optimal levels. This technology ensures that every can is filled to the precise volume, preventing overfills or underfills, which can negatively impact the quality of the product.

Sealing Mechanism: Once the cans are filled, the machine automatically seals them with aluminum or steel lids. The sealing process is essential to maintaining the integrity of the drink while preserving freshness and carbonation. The machine’s sealing mechanism is highly effective, ensuring that the cans are securely sealed without any leakage.

Inspection and Quality Control: After the filling and sealing processes, the drinks canning machine conducts automated quality checks to ensure the cans meet production standards. This includes checking for correct fill levels, proper sealing, and any potential defects in the cans. If any issues are detected, the machine automatically ejects defective cans, ensuring only the highest-quality products make it to the next stage of packaging.

Cans Discharge: Finally, the fully filled and sealed cans are discharged and moved to the next phase of packaging or labeling. The entire process is automated, requiring minimal human intervention and reducing the potential for errors.

Advantages of the Drink Canning Machine

1、High-Speed and High-Capacity Operation

The MIC 12-1 Fully Automatic drinks canning machine is designed to handle between 1000 to 2000 cans per hour, making it ideal for mid-range production capacities. The high-speed operation ensures that production lines can keep up with increasing demand while maintaining optimal efficiency. Whether you’re producing carbonated beverages, juices, or other drinks, this machine guarantees high throughput without compromising quality.

2、Precise Filling and Minimal Waste

Thanks to its advanced filling technology, the canning machine drinks ensures that each can is filled to the exact required level. This precision minimizes product waste, ensuring that no beverage is lost during the production process. For manufacturers, this means better yield and lower operational costs.

3、Versatility for Different Beverage Types

The MIC 12-1 is a versatile drink canning machine that can handle various types of beverages, both carbonated and non-carbonated. Whether you're producing soft drinks, energy drinks, or juices, the machine can be easily adjusted to accommodate different drink types and packaging sizes, making it a highly adaptable solution for your production line.

4、Hygienic Design and Easy Maintenance

Built with hygiene and ease of maintenance in mind, the MIC 12-1 is constructed from high-quality, corrosion-resistant materials. Its design minimizes the buildup of residues, making it easy to clean between production runs. The machine’s components are accessible and designed for quick maintenance, ensuring minimal downtime and efficient ongoing operation.

5、Automatic and Low-Manual Intervention

This fully automatic drinks canning machine reduces the need for manual labor, lowering labor costs and reducing the potential for human error. The machine is equipped with automatic controls that manage the entire canning process, from filling to sealing. The automatic nature of the machine allows operators to focus on other tasks, improving overall productivity.

6、Energy Efficiency

The MIC 12-1 is designed with energy efficiency in mind, optimizing power consumption without sacrificing performance. This helps beverage manufacturers reduce operational costs while maintaining high production levels. The machine’s efficient operation is part of Jiangsu Mic Machinery’s commitment to sustainable manufacturing practices.

7、Customizable for Specific Production Needs

One of the standout features of the MIC 12-1 canning machine drinks is its ability to be customized according to your production needs. Whether you need a specific can size or special filling parameters for a particular beverage, our engineering team can tailor the machine to suit your exact requirements. This flexibility ensures that the MIC 12-1 is a long-term solution that adapts to your business as it grows.

8、Enhanced Product Quality Control

Quality control is a key priority with the MIC 12-1. The machine is equipped with built-in monitoring systems that ensure each can is filled and sealed correctly. This reduces the likelihood of defects reaching the consumer and ensures that your product meets the highest standards of quality.

Conclusion

Jiangsu Mic Machinery’s MIC 12-1 Fully Automatic drink canning machine is an advanced solution for beverage manufacturers looking to streamline their canning process. With its high speed, precision filling, versatility, and ease of maintenance, this machine is an excellent investment for businesses seeking to enhance their production efficiency and product quality.

Whether you're dealing with soft drinks, juices, or carbonated beverages, the MIC 12-1 can help you meet your production goals while maintaining the highest standards of performance and hygiene.

For more information or to request a quote for the MIC 12-1, contact Jiangsu Mic Machinery today. Our team of experts is ready to support you with customized solutions to fit your unique production needs.

MIC 18-6 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | Cold filling, hot filling |

|

Can diameter range |

Ф40-90MM |

|

Can height |

92-168MM |

|

Dimension |

1800*1300*1950mm |

|

Weight |

1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |