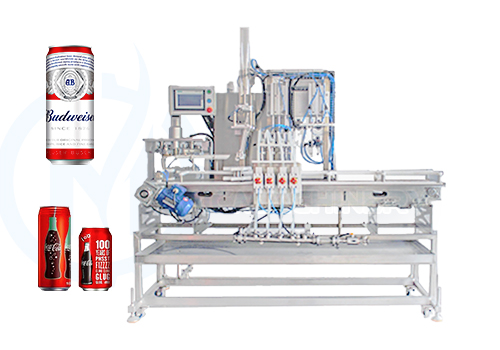

MIC Linear Soda Can Poduction Line (1000-1500CPH)

MIC Linear Soda Can Production Line: Precision and Efficiency in Beverage Packaging

Machine is Suitable For

The MIC Linear Soda Can Production Line is designed to meet the needs of beverage manufacturers seeking high-efficiency production for carbonated drinks. This machine is ideal for filling and packaging a wide range of beverages, including sodas, energy drinks, and soft drinks. The soda can production line is suitable for businesses that require high-speed and consistent production for large-scale operations. It is capable of handling various can sizes and is adaptable to different beverage types, making it an essential asset for any soda production line. The system is perfect for beverage plants focused on producing carbonated drinks in cans, offering flexibility and scalability to meet market demands.

|

|

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Working Principle

The MIC Linear Soda Can Production Line operates on a fully automated system that streamlines every stage of the filling and packaging process. The production line is designed to ensure precision and high throughput while maintaining the quality of each product.

1)Cleaning and Sterilizing

The first stage of the process involves cleaning and sterilizing the cans to ensure that the final product is free from contaminants. The cans are passed through a cleaning station, where they are thoroughly washed and disinfected before the filling process begins.

2)Filling Process

The soda production line uses an advanced filling mechanism to ensure precise and uniform filling of each can. The system is highly efficient, minimizing waste and reducing filling time. With precise filling control, it guarantees that each can is filled to the exact required level.

3)Sealing and Capping: After the cans are filled, they proceed to the capping station, where they are sealed tightly to preserve the contents and ensure freshness. This step is vital for ensuring that the beverages remain sealed and secure throughout the supply chain.

4)Labeling and Packaging: The final stage of the process involves labeling and packaging the filled cans. The labeling system applies product information and branding to each can. The soft drink production line is designed for high-speed packaging, ensuring that each can is packed into cartons or cases efficiently and securely, ready for distribution.

5)Quality Control: Throughout the entire process, integrated quality control mechanisms are in place to monitor every aspect of production. This includes checking for fill levels, seal integrity, and proper labeling to ensure that each can meets the highest quality standards.

Advantages

The MIC Linear Soda Can Production Line offers numerous benefits for beverage manufacturers, making it an indispensable part of any production plant. Its features include:

1.High-Speed Production

The soda can production line is engineered for high-speed operations, allowing manufacturers to increase their production volume without compromising on quality. It is capable of handling a large number of cans per hour, making it ideal for mass production.

2.Precision and Accuracy

With advanced filling and sealing technologies, the line ensures that each can is filled accurately, minimizing waste and maximizing efficiency. This precision helps reduce operational costs and ensures consistency in the final product.

3.Versatility

The MIC Linear Soda Can Production Line is versatile, capable of handling various beverage types, including sodas, energy drinks, and other carbonated beverages. It can be adapted to different can sizes and beverage formulations, making it suitable for a wide range of production needs in the soft drink production line.

4.Reduced Labor Costs

The automation of the filling, capping, and packaging processes reduces the need for manual labor, lowering labor costs and minimizing the potential for human error. This makes the production line both cost-effective and reliable.

5.Durability and Reliability

Built with high-quality components and materials, the MIC Linear Soda Can Production Line is designed for long-lasting performance in demanding production environments. It is durable and can handle continuous operations, ensuring high uptime and minimal maintenance needs.

6.Energy Efficiency

The production line is designed with energy-saving features, which help reduce power consumption during production. This not only lowers operating costs but also supports sustainable practices within the manufacturing process.

7.Integrated Quality Control

With advanced quality control systems built into every stage of the process, the production line ensures that each can is up to standard. This results in a high-quality, consistent product that meets customer expectations.

In summary, the MIC Linear Soda Can Production Line offers an advanced solution for beverage manufacturers looking to optimize their soda production line operations. With its high-speed capabilities, versatility, and integrated quality control, this line ensures maximum efficiency and consistent product quality. Whether you are producing sodas, energy drinks, or other carbonated beverages, this production line is designed to meet the needs of modern beverage manufacturers while maintaining high standards of performance and reliability.

|

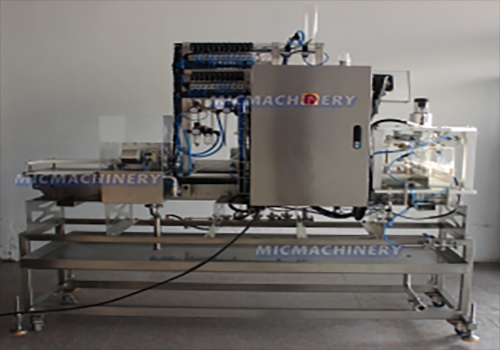

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

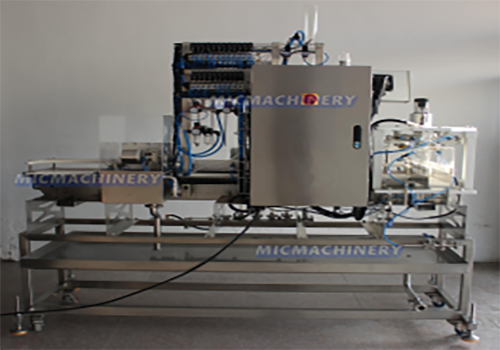

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |