MIC 12-1 Carbonated Drink Production Line (1000-2000CPH)

MIC 12-1 Carbonated Drink Production Line: High-Efficiency Beverage Bottling Solution

Machine is Suitable For

The MIC 12-1 carbonated drink production line is specifically designed for the bottling of carbonated beverages such as sodas, sparkling waters, and energy drinks. This versatile production line is an ideal choice for companies looking to scale up their bottling operations while ensuring consistent quality and efficiency. Whether you're running a soft drink bottling line or an energy drink production line, this system offers the perfect solution for businesses involved in the production of fizzy drinks, with flexible configurations to accommodate various bottle sizes and product types.

|

|

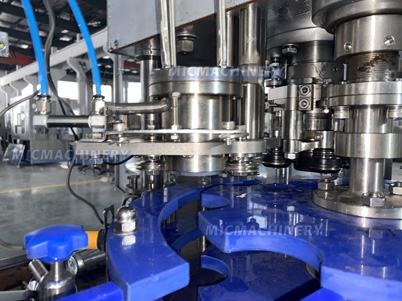

Can filling seaming machine foaming device |

|

Can filling seaming machine liquid tank A Can Filling Seaming Machine Liquid Tank is a storage component that holds the beverage (such as beer or soda) before it is filled into cans. Positioned above the filling station, the tank ensures a steady and consistent supply of liquid to the filling machine. It is designed to maintain the correct pressure and temperature to ensure accurate fills and prevent spillage. The liquid tank typically features precise control systems to regulate liquid levels and flow rates, ensuring smooth and efficient operation of the canning process. |

|

Working Principle

The MIC 12-1 carbonated drink production line operates with a seamless integration of multiple stages, ensuring the efficient production and bottling of carbonated drinks. The process begins with bottle washing, where bottles are cleaned and sterilized before being filled. Once cleaned, the bottles are transported to the filling station, where the carbonated beverage is dispensed. The system is equipped with an advanced filling technology that ensures each bottle is filled with the correct volume of liquid while maintaining carbonation levels. After filling, the bottles are immediately capped to prevent gas loss and ensure freshness. The final step involves labeling, where high-quality labels are applied to each bottle. The entire process is fully automated, with a user-friendly control panel for real-time monitoring and adjustments, optimizing the production process at every stage.

Advantages

The MIC 12-1 carbonated drink production line offers several key advantages, making it an excellent choice for companies in the beverage industry:

1.High Production Capacity

This production line is designed for high-speed bottling, increasing your output without compromising on product quality, making it perfect for large-scale production runs of carbonated drinks, energy drinks, or sodas.

2.Versatility

Whether you are running a soft drink bottling line, an energy drink production line, or a carbonated drink production line, this system is adaptable to meet the needs of a wide range of beverages, from soft drinks to sparkling waters and energy drinks.

3.Advanced Filling Technology

The state-of-the-art filling system ensures precise and uniform filling of each bottle, preserving the carbonation and reducing waste, which is essential for high-quality carbonated beverages.

4.User-Friendly Control System

The easy-to-use control panel allows for seamless operation, giving operators the ability to adjust settings, monitor production, and troubleshoot issues in real-time.

5.Energy Efficiency

The MIC 12-1 production line is designed to minimize energy consumption, helping companies reduce operational costs while maintaining high production speeds.

6.Durability and Reliability

Built with robust materials and high-quality components, this line is designed for long-lasting performance, even in demanding high-speed environments.

7.Low Maintenance

With its durable construction and automated features, the MIC 12-1 carbonated drink production line requires minimal maintenance, leading to reduced downtime and lower operational costs.

8.Cost-Effective

The combination of high efficiency, low maintenance, and energy-saving features makes this production line a cost-effective solution for businesses looking to enhance their bottling capabilities.

The MIC 12-1 carbonated drink production line is an advanced, reliable, and efficient system that offers a seamless bottling solution for businesses in the beverage industry. With cutting-edge technology and a focus on performance, it ensures that your production process is optimized for high-quality output. Whether you're working with carbonated soft drinks, energy drinks, or other sparkling beverages, this line is the perfect choice for modern bottling operations.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |