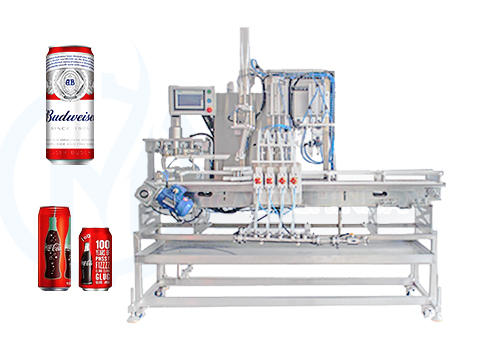

MIC Linear Drinks Canning Machine (1000-1500CPH)

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer of advanced packaging solutions in the beverage industry. With years of experience and a commitment to innovation, we design and produce high-performance machines that meet the diverse needs of our clients. Our focus on quality, reliability, and customer satisfaction has earned us a trusted reputation among beverage manufacturers worldwide.

As a forward-thinking company, Jiangsu Mic Machinery is dedicated to optimizing production lines with cutting-edge technology. The MIC Linear cocktail canning machine is one of our flagship products, engineered to support medium-scale production needs while maintaining high-speed performance and precision. We take pride in offering machines that provide excellent value, helping our clients enhance productivity, reduce costs, and ensure superior product quality.

|

|

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Introducing the MIC Linear Drinks Canning Machine (1000-1500CPH)

At Jiangsu Mic Machinery, we specialize in providing state-of-the-art beverage packaging solutions that cater to a wide range of production needs. Our MIC Linear drinks canning machine (1000-1500CPH) is designed to deliver high-quality canning capabilities for medium-scale production lines. This machine is ideal for manufacturers seeking reliable, efficient, and precise canning of beverages, from soft drinks to cocktails. Below, we outline the key features and advantages of this exceptional product.

Features of the Drink Canning Machine

The MIC Linear drinks canning machine is built for efficiency and versatility, ensuring that your production line runs smoothly and reliably. Here are the key features that set this machine apart:

Linear Design for High Efficiency: The machine’s linear design optimizes space utilization and allows for smooth canning operations. The design minimizes the need for complex mechanisms, leading to lower maintenance requirements and a more straightforward operation. This simplicity also helps improve overall operational efficiency.

Precision Filling System: The MIC Linear canning machine drinks is equipped with a precision filling system that ensures consistent filling across all cans, avoiding overfill or underfill. This system is ideal for various beverage types, from carbonated drinks to non-carbonated beverages and even cocktails, offering versatility across different product lines.

Flexible Production Capacity: This machine operates at speeds of 1000-1500 cans per hour, making it the perfect solution for medium-scale beverage manufacturers. Whether you’re producing soft drinks, energy drinks, or cocktail canning machine beverages, the MIC Linear machine can accommodate your specific production needs, offering the flexibility to switch between different beverage types with ease.

Integrated Control System: The MIC Linear drinks canning machine features an advanced control system that provides real-time monitoring and data tracking. The system ensures that all processes, from can feeding and filling to sealing and packaging, operate seamlessly, with automatic adjustments made when needed for optimal performance.

Compact and Space-Saving Design: Designed to fit in limited spaces, this machine offers a compact solution for beverage producers looking to maximize floor space. Despite its small footprint, it maintains high efficiency, making it an excellent choice for factories with space constraints.

Enhanced Hygiene and Safety: Hygiene is a key concern in beverage production, and the MIC Linear cocktail canning machine is designed with hygiene in mind. It features smooth surfaces, quick-release parts, and a self-cleaning system that minimizes contamination risk and ensures compliance with food safety standards.

Advantages of the Drink Canning Machine

The MIC Linear canning machine drinks offers numerous benefits that help enhance the productivity, efficiency, and cost-effectiveness of your production line:

1、Versatile Application for Various Beverages

This cocktail canning machine is adaptable to a wide range of beverages, from fizzy sodas and sparkling waters to fruit juices and cocktails. Whether you’re looking to package carbonated drinks or non-carbonated beverages, the MIC Linear can handle the job without compromising on quality or speed.

2、Improved Product Quality

The precision filling system ensures that every can is filled to the perfect level, maintaining consistency and eliminating the risk of spillage or underfilling. This leads to less product waste and ensures that the final product meets the highest standards, enhancing customer satisfaction and brand reputation.

3、Cost-Effective Solution for Medium-Scale Producers

With its efficient design and moderate speed range, the MIC Linear drink canning machine is a highly cost-effective option for medium-scale producers. It offers a great balance between affordability and performance, providing maximum value for businesses that need reliable canning capabilities at an affordable cost.

4、Reduced Operational Costs

The streamlined design reduces energy consumption, while the automated control system minimizes the need for manual labor. These efficiencies lower operational costs, helping businesses improve their bottom line while maintaining high-quality production standards.

5、Ease of Integration

The MIC Linear machine is designed for easy integration into existing production lines. Its simple layout and operation ensure minimal disruption when adding it to your facility. Furthermore, its compatibility with a wide range of beverage types makes it an excellent choice for companies looking to diversify their product offerings.

6、Low Maintenance Requirements

With fewer moving parts and a design focused on durability and reliability, the MIC Linear canning machine drinks requires less maintenance than other, more complex machines. This reduces downtime and minimizes the costs associated with repairs, ensuring that your production runs smoothly.

Conclusion

The MIC Linear drinks canning machine (1000-1500CPH) is an ideal solution for medium-sized beverage manufacturers who need a cost-effective, reliable, and versatile canning system. With its efficient design, precision filling, and high-quality standards, it is an excellent choice for companies looking to scale their production without compromising on product quality.

At Jiangsu Mic Machinery, we are committed to providing top-quality packaging solutions to the beverage industry. Our MIC Linear cocktail canning machine is just one example of the many advanced, innovative products we offer to help our clients improve their production efficiency, reduce costs, and boost their business growth.

Contact us today to learn more about how the MIC Linear canning machine drinks can benefit your production line and help meet your operational goals.

|

Equipment Parameter |

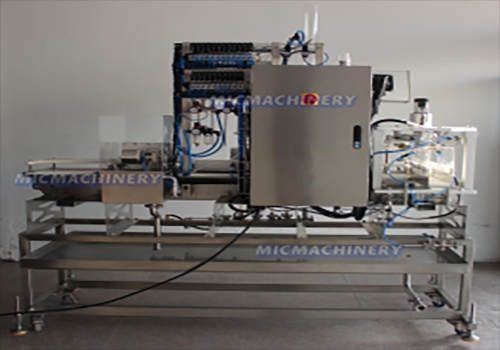

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |