MIC Fruit Juice Production Line (3000BPH)

MIC Fruit Juice Production Line: Product Introduction

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer of high-quality machinery for the beverage and food processing industries. With a focus on innovation, efficiency, and customer satisfaction, we offer a comprehensive range of equipment that meets the ever-evolving needs of our clients. Our fruit juice production line is one of our flagship products, designed to deliver precision and high efficiency for all stages of the juice production process.

As an industry leader, we understand the importance of maintaining both speed and quality in beverage production. Our juice filling line and orange juice production line are engineered to optimize production output while ensuring that each bottle meets the highest safety and quality standards. Our machines are used globally by companies looking to expand their production capabilities and deliver high-quality beverages to their consumers.

|

|

Capper Station A Capper Station is a key component in packaging lines, automatically applying caps to bottles or containers. It ensures precise capping, increases production efficiency, and minimizes human error. |

|

Cap arranging unit A Cap Arranging Unit efficiently organizes and arranges caps for automatic capping machines, ensuring smooth production flow, reducing downtime, and enhancing overall packaging efficiency. |

|

|

|

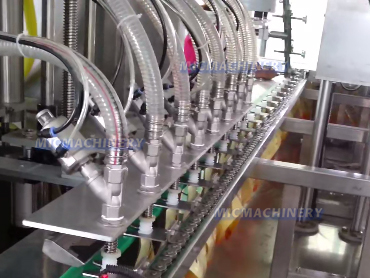

Filling Head A Filling Head is a crucial part of liquid filling machines, designed to accurately dispense liquids into bottles or containers. It ensures consistent filling volume, reduces spills, and enhances production efficiency. |

Features

The MIC fruit juice production line incorporates cutting-edge technology to ensure high performance and versatility, making it an ideal solution for manufacturers looking to streamline their juice production processes. Some key features of the machine include:

· Comprehensive Juice Processing: The fruit juice production line is designed to handle a variety of fruit juices, including orange, apple, and mixed juices, making it perfect for companies looking to offer diverse products. The machine can handle the entire process, from washing and sterilizing fruit to filling and capping.

· Precision Filling: The juice filling line uses advanced filling technology that ensures precise measurement and filling of juices into containers, minimizing waste and improving production efficiency. The system is designed to handle various container sizes and types, including bottles and cartons.

· High-Speed Production: The MIC fruit juice production line is optimized for high-speed production, ensuring that large volumes of juice can be produced in a short amount of time. This high-speed capability is particularly beneficial for businesses with large-scale production needs, helping them meet market demands with ease.

· Energy Efficiency: The machine is built to operate with minimal energy consumption while maintaining peak performance, which helps reduce operational costs for businesses in the long term.

· Hygiene and Safety: The entire system is built with food-grade materials, and all contact parts are designed to meet stringent hygiene and safety standards. The design minimizes contamination risks and ensures that the juice produced is safe for consumers.

· Flexible Configuration: The orange juice production line is highly adaptable and can be customized according to the specific needs of the production facility. Whether you need to scale production or switch between juice types, the system offers flexibility to accommodate changing requirements.

Advantages

The MIC fruit juice production line offers several advantages that set it apart in the market, making it the preferred choice for many beverage manufacturers:

1.Increased Production Efficiency

With its automated systems and high-speed capabilities, the juice filling line significantly reduces manual labor, increases output, and minimizes production time. This leads to greater productivity and better ROI for manufacturers.

2.Cost-Effective Operation

The energy-efficient design and low maintenance requirements of the fruit juice production line contribute to a lower overall operating cost. Businesses can achieve high production volumes with minimal resource consumption, leading to increased profitability.

3.Scalability

The system is highly scalable, allowing businesses to expand their operations as demand for their products grows. Whether you are producing small batches or large volumes, the MIC fruit juice production line can easily be adjusted to meet your needs.

4.Consistent Quality

The machine ensures that every bottle of juice meets the same high-quality standards, with uniform filling levels and consistent taste. The orange juice production line is specifically designed to maintain the quality and flavor of the juice, preserving its freshness throughout the production process.

5.Ease of Maintenance

The MIC fruit juice production line is designed for easy maintenance with user-friendly controls and quick access to critical components. This reduces downtime and ensures continuous production.

6.Environmental Sustainability

With its energy-efficient design and minimal waste production, the juice filling line helps companies reduce their carbon footprint while maintaining high levels of output.

In conclusion, the MIC fruit juice production line offers an ideal solution for companies looking to enhance their juice production capabilities. Whether you're manufacturing orange juice, apple juice, or mixed fruit juices, this machine combines speed, efficiency, and flexibility to meet the needs of modern beverage production. At Jiangsu Mic Machinery, we provide high-quality, durable equipment designed to help you scale your operations and improve profitability.

| Filling Range | 250-2000ml |

| Voltage | 220v/380v |

| Power | 4KW |

| Filling Precision | 99% |

| Filling Nozzles | 8 nozzles |

| Filling Speed | 3000 BPH |

| Dimension | 3800*1500*2200mm |

| Weight | 1000kg |

| Material | SS304 |

| Touch screen | Xinjie |

| PLC | Schneider |

| Solenoid valve | AirTAC |

| Optoelectronic system | AUTONICS |

| Differential switch | Netherlands |

| Air source treatment | AirTAC |

| Switching power | MingWei |

| Button and other low-voltage electrical appliances | Schneider |

| Alarm system | Real-time fault alarm, important fault can automatically stop |

| Servo motor | TECO |

| Ball screw | Taiwan |

| Function | Filling the count |

| Material | 316 stainless steel is used in contact with material, 304 stainless steel is used in other main parts. |

| Sealing ring | It is made of carbon tetrafluoro fibers with good anticorrosion, wear resistance and sealing. |

| AC contactor | Schneider |

| Thermorelay | Schneider |

| Transducer | Schneider |

| Double clutch | Custom |

| Precision relief valve | Lark |

| Screw cap form | Automatic cap sorting and capping |

| One camera dual use | Fillable Water Agent or Thickener Formula |