MIC Drink Production Line ( 200-800BPH)

MIC Drink Production Line

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer specializing in providing high-quality beverage production and packaging solutions. With extensive expertise in the field, we design and manufacture a range of automated and semi-automated machines for the production of carbonated drinks, soft drinks, and other beverages. Our drink production lines are built to ensure maximum efficiency, precision, and flexibility in your production process. Whether you're producing sparkling water, sodas, or other soft drinks, our machines are engineered to meet the diverse needs of modern beverage production. We are committed to delivering cost-effective, reliable, and high-performance solutions for beverage manufacturers around the globe.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

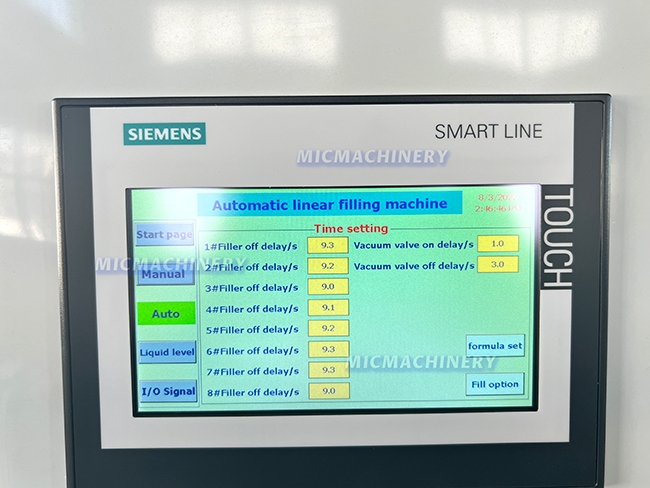

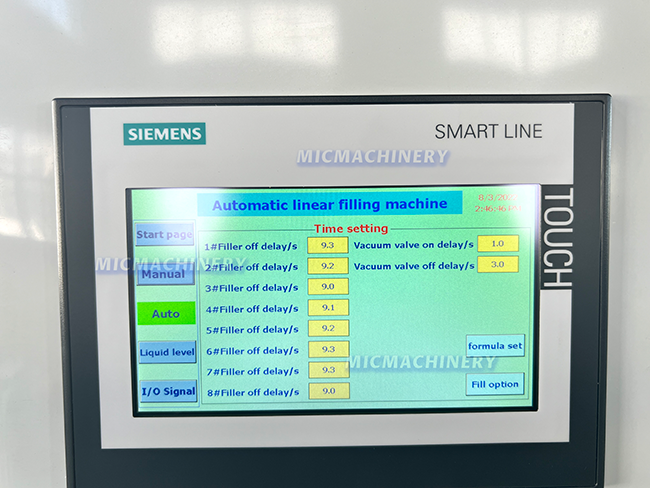

Control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Features

The MIC drink production line is a versatile and fully integrated system designed to streamline every step of beverage production, from bottle washing and filling to sealing and packaging. Below are the key features of the system:

· Efficient Bottle Washing: The production line begins with an automated washing station that effectively cleans bottles, ensuring they are free from contaminants before they are filled. This step is essential for maintaining the quality and safety of the final product.

· Filling Technology: The soft drink production line utilizes advanced filling technology to ensure precise and accurate filling of each bottle. The system minimizes product waste and ensures consistency across batches. This feature is crucial for maintaining high standards in beverage quality and volume.

· Flexible Sealing and Capping: The sealing and capping stages are designed to handle a wide range of bottle types and sizes. Whether it’s plastic, glass, or other packaging materials, our soft drink bottling lines can efficiently seal and cap bottles with various closure types, ensuring a secure and leak-proof product.

· Labeling and Packaging: After filling and sealing, the bottles are moved to the labeling and packaging stations. The line integrates high-precision labeling equipment to apply product labels, barcodes, and other necessary information onto each bottle, readying them for distribution.

· Automation and Control: The production line is equipped with an advanced control system that allows for seamless operation, reduced downtime, and improved overall productivity. Operators can monitor and adjust settings through an intuitive interface, allowing for greater control and ease of use.

· Customizable Production Options: The soft drink production line is designed to handle a variety of beverage types, from still drinks to carbonated soft drinks. Its flexible nature allows manufacturers to switch between different beverage formulations with minimal downtime.

· Energy Efficiency: With energy-saving features integrated into the system, the line is designed to minimize resource usage while maximizing output, ensuring an environmentally friendly and cost-effective solution for beverage production.

Advantages

The MIC drink production line offers a range of advantages that make it an ideal choice for beverage manufacturers looking to optimize their production processes:

High Production Efficiency: With a combination of automated and semi-automated processes, the system ensures high throughput with minimal human intervention. This results in significant time and cost savings, allowing for faster production cycles and more efficient operations.

Cost-Effective: Our soft drink bottling lines are built to provide an excellent return on investment. By reducing labor costs and minimizing waste, these machines offer cost-effective solutions for beverage manufacturers of all sizes.

Product Quality Control: The system includes built-in quality control features to ensure consistent filling, accurate sealing, and precise labeling. Every bottle produced is checked for quality, reducing the risk of defective products and maintaining the reputation of your brand.

Scalability: The MIC drink production line is scalable, meaning it can be adapted to meet the growing needs of your business. As your production requirements expand, the line can be easily upgraded or integrated with additional machines to increase capacity.

User-Friendly Operation: With an easy-to-use interface and intuitive controls, operators can quickly adapt to the system and ensure smooth, uninterrupted production. The system is designed to minimize operator errors and improve overall productivity.

Versatility: From flavored waters and energy drinks to classic sodas, the soft drink production line can handle a variety of drink types. This flexibility makes it suitable for a wide range of beverage manufacturers who wish to diversify their product offerings.

Low Maintenance: With durable components and low wear-and-tear design, the system requires minimal maintenance, reducing operational downtime and ensuring long-term reliability.

In conclusion, the MIC drink production line offers the perfect balance of efficiency, flexibility, and reliability. Whether you are looking to produce soft drinks, sodas, or energy drinks, our line provides everything you need to streamline your production process and meet the demands of today’s competitive beverage market. At Jiangsu Mic Machinery, we are committed to delivering solutions that help you improve your production efficiency while maintaining the highest product quality standards.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |