MIC Drink Packaging Machine ( 200-800BPH)

Company Introduction

At Jiangsu Mic Machinery, we specialize in high-quality, advanced machinery for the beverage industry. With years of expertise in designing and manufacturing innovative equipment, our company has become a trusted name in drink packaging solutions. Our dedication to precision engineering, superior customer service, and continuous technological improvements enables us to offer state-of-the-art products like the drink packaging machine. We are committed to meeting the evolving demands of our global customers, delivering reliable, efficient, and sustainable machinery to ensure smooth operations for beverage producers worldwide.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

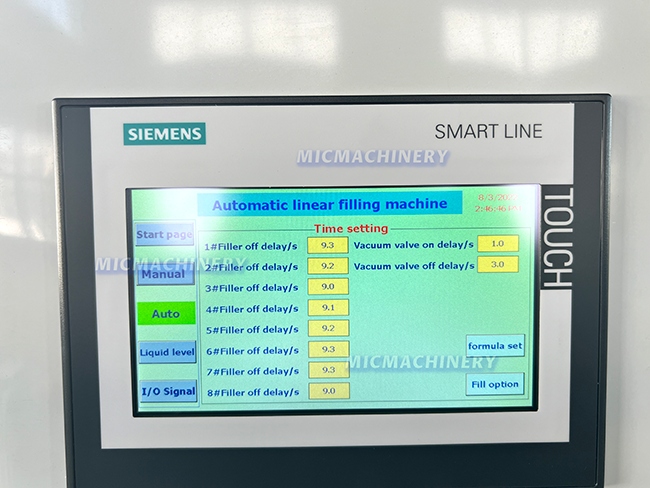

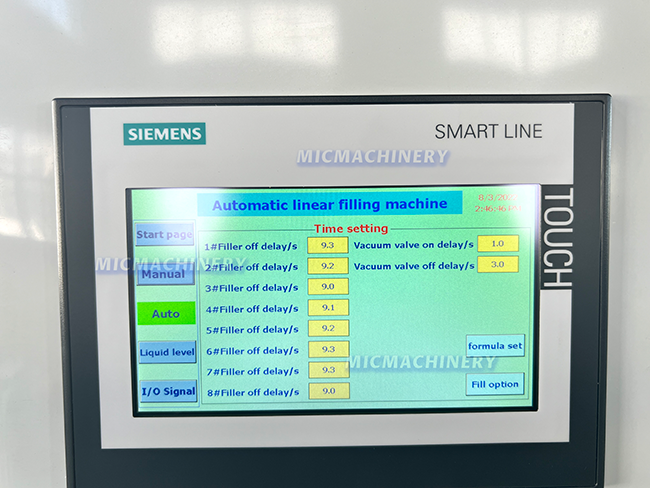

Control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Features of the Drink Filling Machine

The drink filling machine from Jiangsu Mic Machinery is a cutting-edge solution for various beverage packaging needs. This versatile machine is designed to accommodate a wide range of liquid products, including both carbonated and non-carbonated drinks. One of its key features is its precision filling system, which ensures consistent filling volumes with minimal spillage, increasing production efficiency and reducing waste.

Our cold drink packaging machine is equipped with advanced temperature control technology to maintain the ideal filling temperature for cold beverages, preserving their freshness and flavor. The machine also integrates high-quality sealing mechanisms that guarantee secure and leak-proof packaging, even under high-speed operations. With its user-friendly interface, operators can easily adjust settings to suit different bottle sizes and packaging specifications, streamlining the production process.

Advantages of the Drink Filling Machine

The drink packaging machine offers a host of advantages that set it apart from other machines in the market. First and foremost, its high-speed operation minimizes downtime, boosting overall productivity and throughput. Whether it's a small-scale production run or a high-volume bottling line, this machine can handle diverse production demands with ease.

Moreover, the machine is designed for easy maintenance and longevity, reducing the need for frequent repairs and parts replacements. The robust construction ensures that it withstands long-term wear and tear, making it a cost-effective investment for beverage producers. Additionally, the drink filling machine is highly energy-efficient, helping businesses reduce operational costs while maintaining optimal performance.

With advanced automation and safety features, the cold drink packaging machine ensures that every step of the filling and packaging process is performed with the utmost care, safeguarding both the product quality and the operator’s safety. It’s an ideal choice for companies looking to optimize their packaging operations without compromising on quality.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |