Carbonated Drink Mixer

Carbonated Drink Mixer – Efficient Blending Solutions by Jiangsu Mic Machinery

Process Features

The carbonated drink mixer is designed to deliver superior carbonation and flavor uniformity for beverages. This soda mixer machine ensures rapid and efficient blending, making it ideal for high-demand production lines. The machine incorporates advanced technology to achieve consistent gas infusion, resulting in high-quality carbonated drinks every time. With its precision mixing capabilities, this equipment allows manufacturers to easily meet the rigorous demands of the beverage industry.

The mixing machine offers customizable settings, enabling manufacturers to control the level of carbonation and flavor integration. It is engineered to handle a variety of drink types, from soft drinks to sparkling water, providing versatility and efficiency for different production needs.

|

|

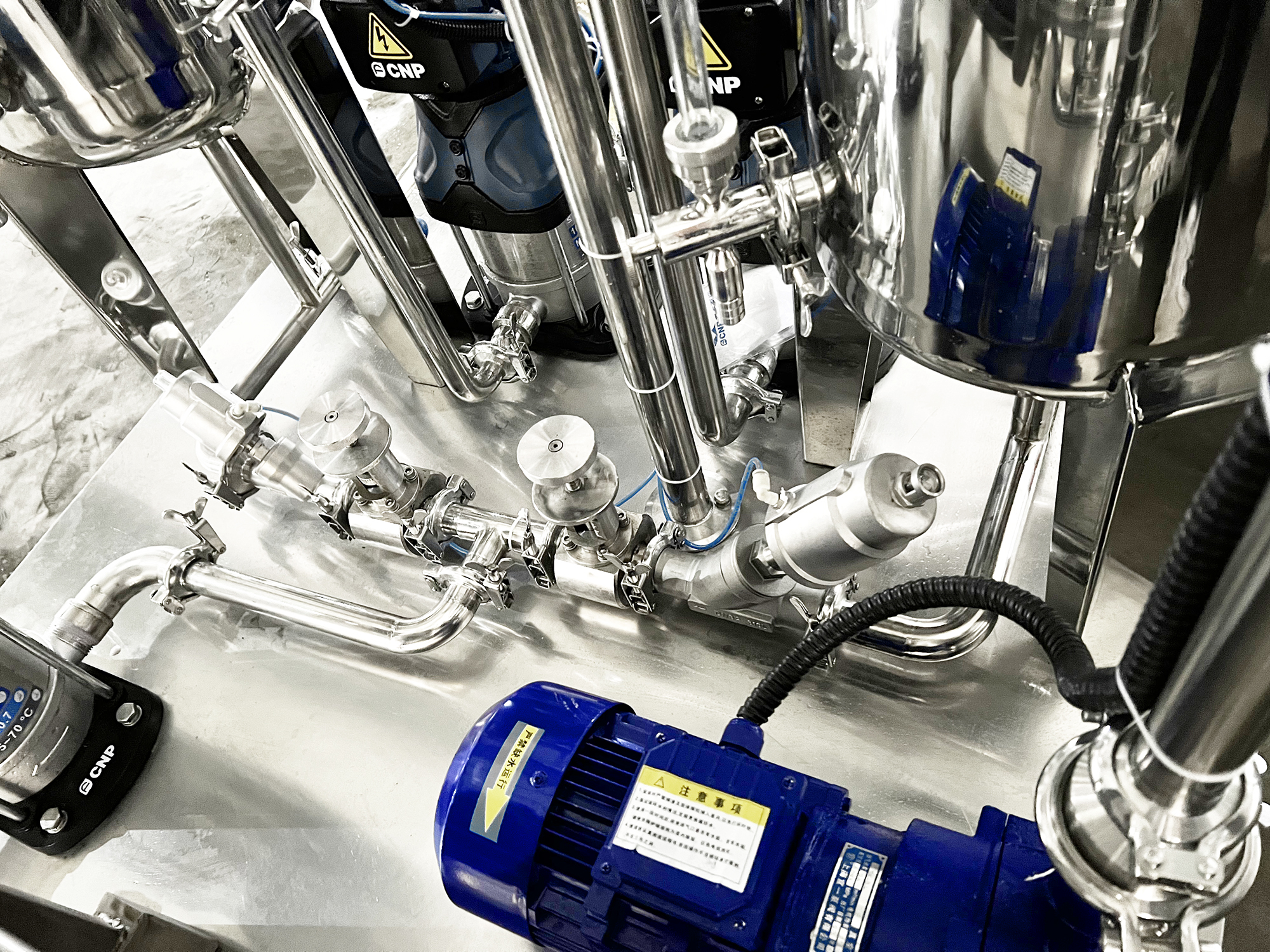

Piping and Pump System The Piping and Pump System with Mixing Machine is designed for seamless integration in industrial processes. It efficiently transfers materials while providing consistent mixing, ensuring high-quality production. Ideal for applications in food, beverage, and pharmaceutical industries, it ensures reliability and performance. |

|

Pressure Valve The Pressure Valve with Mixing Machine is an essential component for controlling fluid pressure during the mixing process. It ensures safe and efficient operation by maintaining optimal pressure levels, preventing overflows or pressure build-up. Perfect for industries like food, pharmaceuticals, and chemicals. |

|

|

|

Control Panel The Control Panel with Mixing Machine combines advanced automation with efficient mixing capabilities. It allows precise control over mixing processes, ensuring consistency and quality.

|

Main Components and Functions

1、High-Speed Mixing Chamber

The carbonated drink mixer utilizes a high-speed mixing chamber that facilitates quick and uniform carbonation. This ensures that gas is evenly distributed throughout the liquid, providing the desired fizziness for every batch.

2、Gas Injection System

Equipped with a precise gas injection system, the soda mixer machine controls the infusion of carbon dioxide into the liquid. The system ensures that the carbonation level is consistent, improving both the taste and mouthfeel of the final product.

3、Pump and Pressure Regulation

The mixing machine is fitted with high-performance pumps and pressure regulation systems, allowing smooth transportation of liquids and maintaining optimal pressure for effective carbonation.

4、Stainless Steel Construction

Constructed from high-quality stainless steel, the carbonated drink mixer is durable, easy to clean, and resistant to corrosion, ensuring longevity and hygiene in production environments.

5、Automation and Control Panel

The soda mixer machine features an automated control panel that simplifies operation and ensures accurate control over mixing parameters. This allows operators to adjust settings for various production requirements with ease.

Conclusion

Jiangsu Mic Machinery’s carbonated drink mixer offers efficient and consistent mixing for beverage manufacturers. The soda mixer machine is engineered with high-quality components to provide superior carbonation and blending, ensuring the highest product quality. Whether you're producing soft drinks, sparkling beverages, or carbonated water, our mixing machine provides the reliability and performance you need to keep your production lines running smoothly. Contact us today to learn more about our advanced mixing solutions.

|

Capability

|

carbonated drink 2T/H

|

|

Mixing ratio range of water to sugar

|

3:1--6:1

|

|

Product CO2 content

|

2.0-3.5

|

|

Product temperature

|

less than 4°C

|

|

Power consumption

|

about 5KW

|

|

Plate heating exchanger area

|

10㎡

|

|

Overall size

|

(L*W *H) 1500*1200*2200 (mm)

|

|

Net weight

|

1500kg

|

|

Drink water (clear water after purification)

|

0.25--0.35MPa

|

|

Syrup

|

0.10--0.15MPa

|

|

Carbonic acid gas(CO2)

|

0.8--1.0MPa, purity 99.99%

|

|

Compressed air

|

0.6--0.8MPa

|

|

PLC

|

Mitsubishi

|

|

Low-voltage apparatus

|

Schneider

|

|

Touchscreen

|

WEINVIEW

|

|

Pneumatic equipment

|

Airtac

|