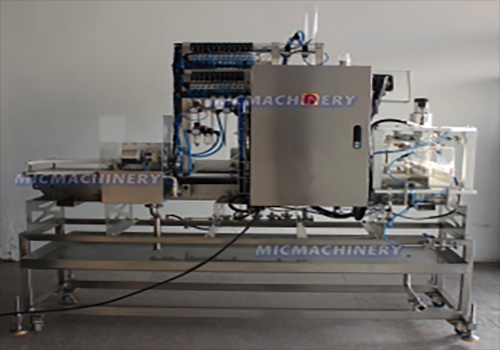

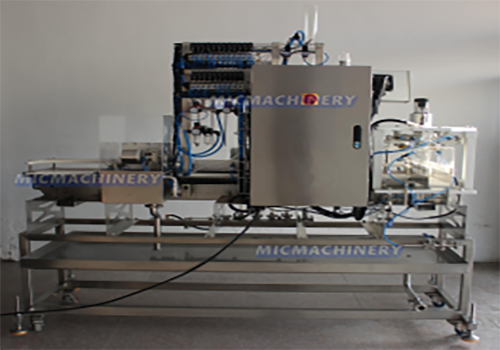

MIC Beer Production Line (1000-1500CPH)

MIC Beer Production Line

At Jiangsu Mic Machinery, we take pride in delivering state-of-the-art solutions for breweries seeking efficient and reliable production equipment. Our MIC Beer Production Line is designed to enhance the brewing process, from brewing and filling to packaging, offering seamless integration with existing systems. With our commitment to precision engineering, this line ensures the highest quality standards for your beer while optimizing production efficiency.

This beer production line is engineered to handle the entire beer production process, offering versatility for both large and small breweries. Whether you’re looking to improve efficiency or expand your brewing capacity, this system provides the performance, flexibility, and reliability you need. It is equipped with advanced technologies to deliver consistent results and minimize downtime, ensuring smooth operations at every stage of the production process.

|

|

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Equipment Features

The MIC Beer Production Line includes essential components such as a brewery canning line and a bottling line, each designed to meet the growing demands of the beverage industry. Our brewery canning line is specifically designed to handle large volumes of beer, efficiently filling cans while maintaining carbonation and quality. The system is engineered with precise filling heads that guarantee accurate fills for each can, ensuring consistency in volume and pressure.

For breweries focused on expanding their packaging capabilities, our canning line brewery equipment is fully customizable to meet specific requirements. It can be adapted to fill different sizes and types of cans, providing flexibility in production. The system is also equipped with advanced capping and sealing technology to ensure a perfect seal on every can, preserving freshness and carbonation for a longer shelf life.

Advantages of MIC Beer Production Line

1.Complete Production Solution

The MIC Beer Production Line integrates all stages of production, including brewing, filling, and packaging, providing breweries with an efficient, all-in-one system.

2.High Efficiency

With advanced automation features, this line offers high-speed operation, reducing downtime and maximizing output. The brewery canning line ensures quick and accurate canning, improving overall production capacity.

3.Quality Control

Our system is designed to maintain the highest quality standards, ensuring your beer is filled, sealed, and packaged consistently. The canning line brewery equipment minimizes the risk of contamination and ensures that the final product retains its freshness and carbonation.

4.Customization Options

The beer production line can be tailored to meet the specific needs of your brewery, whether you’re bottling or canning. The flexibility in production allows breweries to efficiently switch between different packaging formats without significant downtime.

5.User-Friendly Interface

Our equipment is designed with the operator in mind, offering easy-to-use interfaces and controls for seamless operation. Operators can quickly adjust settings to ensure the system performs at its best throughout the production process.

6.Durable and Reliable: Built with high-quality materials, the MIC Beer Production Line is engineered to withstand the demands of a busy brewery environment, ensuring long-lasting durability and minimal maintenance.

The MIC Beer Production Line is an ideal solution for breweries looking to streamline their production processes while maintaining the highest standards of quality. Whether you're a small craft brewery or a larger production facility, this line offers the flexibility, efficiency, and reliability needed to keep up with market demands. With its advanced features and customizable options, the beer production line provides breweries with a competitive edge, delivering high-quality beer to consumers efficiently and consistently.

|

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |