MIC 12-1 Beer Line (1000-2000CPH)

MIC 12-1 Beer Line: Efficient, High-Quality Beer Production

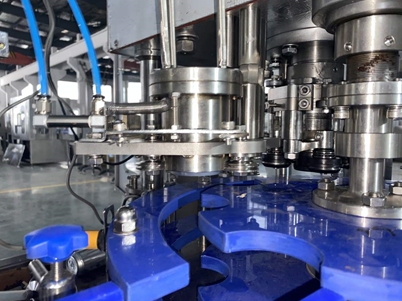

Jiangsu Mic Machinery is proud to introduce the MIC 12-1 beer line, a state-of-the-art solution for breweries seeking high efficiency and precision. Our beer canning line is designed with advanced technology to ensure that every aspect of the beer filling process meets the highest industry standards.

This beer production line is specifically tailored to provide fast, reliable, and accurate filling, capping, and packaging of beer bottles or cans. With its robust construction and easy-to-operate features, the MIC 12-1 beer line supports a wide range of production scales, from small craft breweries to larger, industrial-scale operations.

|

|

Foaming Device |

|

Liquid Tank A Can Filling Seaming Machine Liquid Tank is a storage component that holds the beverage (such as beer or soda) before it is filled into cans. Positioned above the filling station, the tank ensures a steady and consistent supply of liquid to the filling machine. It is designed to maintain the correct pressure and temperature to ensure accurate fills and prevent spillage. The liquid tank typically features precise control systems to regulate liquid levels and flow rates, ensuring smooth and efficient operation of the canning process. |

|

Key features of the MIC 12-1 beer canning line include

· High-Speed Operation: Designed to handle up to 2000 bottles per hour, the MIC 12-1 ensures your brewery’s production remains efficient and fast without sacrificing quality.

· Precision Filling: This beer production line offers accurate filling, minimizing product loss and ensuring consistent levels in every bottle or can.

· Durability and Reliability: Built with premium materials and engineered for continuous, high-demand use, the MIC 12-1 beer line guarantees longevity and minimal downtime.

· Advanced Automation: The line features automated control systems that streamline production, making it easy to monitor and adjust settings for optimal performance.

· Easy Maintenance: With simple design and accessible components, the MIC 12-1 beer canning line is user-friendly and requires minimal maintenance, ensuring smooth operations.

Jiangsu Mic Machinery continues to lead in the beer production line sector by delivering cutting-edge equipment designed to elevate brewery productivity while maintaining the highest quality standards. Trust the MIC 12-1 for your next brewing project and experience unmatched performance in every batch.

Let us help you enhance your beer production process with our reliable and efficient equipment.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

More Model And Speed Click

| Model | MIC 12-1 | MIC 18-1 | MIC 18-6 | MIC 24-6 | MIC 32-8 |

| Application | Beer, Carbonated Beverage, Gas Drinks, Cold Coffee, Sparking Water, Cider, Soda Water, Herbal Tea, Non-Carbonated Drinks And So On | ||||

| Packing Type | Aluminum Cans, Metal Cans, Tin Cans, Pet Cans Etc | ||||

| Speed | 1000-2000CPH | 1000-2500CPH | 3000-6000CPH | 4000-8000CPH | 6000-10000CPH |

| Filling Arrange | 180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) | ||||

| Power | 1.1kw | 1.5kw | 2.5kw | 3.5kw | 4.2kw |

| Size | 1.8*1.3*1.95 (M) | 1.9*1.3*1.95(M) | 2.3*1.4*1.9(M) | 2.58*1.7*1.8(M) | 2.8*1.7*1.95(M) |

| Weight | 1800KG | 2100KG | 2500KG | 3000KG | 3800(KG) |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |