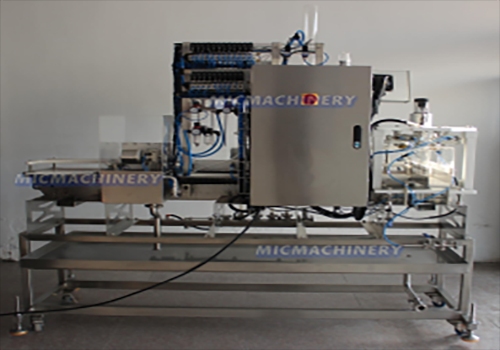

MIC Beer Can Filling Machine (1000-1500CPH)

MIC Beer Can Filling Machine: Precision and Efficiency for Brewerie

The MIC Beer Can Filling Machine from Jiangsu Mic Machinery is a high-performance solution designed to streamline the beer packaging process for breweries of all sizes. Whether you're looking to improve your existing production line or expand your operations, this beer canning machine provides the precision, speed, and reliability you need. With advanced technology and user-friendly features, the MIC Beer Can Filling Machine is an essential tool for breweries aiming to maintain quality while maximizing efficiency.

|

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality.

|

|

|

Conveyor |

Key Features of the MIC Beer Can Filling Machine

1、High Precision and Consistency

As a leading beer can filling machine, the MIC model ensures high precision with each fill. It is engineered to handle beer with varying viscosities, providing consistent fill levels across all cans. This guarantees minimal waste and maintains product consistency, which is essential for breweries committed to delivering quality beer.

2、Efficient and Fast Operation

Designed for high-speed production, the MIC Beer Can Filling Machine boosts your brewery's output without compromising on quality. This beer canning machine operates at impressive speeds, allowing your brewery to keep up with high-demand production schedules. Whether you are bottling for seasonal releases or regular runs, this machine offers the efficiency needed to meet your production goals.

3、Versatile and Adaptable

The MIC Beer Can Filling Machine is versatile enough to handle different can sizes, from smaller craft beer cans to larger formats. This flexibility allows breweries to adapt the system to different beer styles and packaging requirements. The beer canning machine for sale is perfect for small craft breweries as well as larger producers who require scalability and adaptability in their production lines.

4、Integrated Sealing System

Equipped with an integrated can sealing system, the MIC Beer Can Filling Machine ensures that every can is tightly sealed, preserving the freshness and carbonation of the beer. This feature minimizes contamination risks and prevents leakage, ensuring that your product stays in top condition from production to distribution.

5、User-Friendly Interface

The machine is designed with a simple and intuitive control panel that allows brewery operators to easily manage the entire filling and sealing process. The easy-to-use interface minimizes training time, making it accessible even for operators with minimal experience. Real-time monitoring and adjustments can be made quickly to optimize production efficiency.

6、Durability and Low Maintenance

Built from high-quality materials, the MIC Beer Can Filling Machine is designed to last. The machine requires minimal maintenance, reducing downtime and operational costs. Its robust construction is ideal for long-term use in the demanding environment of a brewery, ensuring reliability even in high-volume production.

7、Energy Efficient

The MIC Beer Can Filling Machine is designed with energy efficiency in mind. It operates with minimal power consumption, helping breweries lower their operational costs while maintaining peak performance.

Why Choose Jiangsu Mic Machinery?

At Jiangsu Mic Machinery, we specialize in delivering innovative, high-quality packaging solutions for the brewing industry. The MIC Beer Can Filling Machine is just one example of our commitment to providing efficient and reliable machinery that enhances the beer production process. With years of expertise and a focus on customer satisfaction, we offer tailored solutions to help breweries succeed in an increasingly competitive market.

Our team is dedicated to ensuring that every piece of equipment is perfectly suited to your brewery's needs, whether you are a small craft brewery or a large-scale producer. We pride ourselves on our professionalism, support, and ability to deliver equipment that meets the highest standards of performance and reliability.

If you are looking for a beer canning machine for sale that offers efficiency, reliability, and precision, look no further than Jiangsu Mic Machinery. Contact us today to learn more about how our MIC Beer Can Filling Machine can improve your beer packaging process and boost your brewery's productivity.

|

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |