MIC 12-1 Beer Canning Machine (1000-2000CPH)

MIC 12-1 Automatic Beer Canning Machine: Precision and Efficiency for Craft Breweries

The MIC 12-1 Automatic Beer Canning Machine is an advanced solution for breweries seeking to streamline their packaging process. Designed for high efficiency and reliability, this beer canning machine is the ideal choice for craft breweries and commercial operations alike. Whether you're looking to increase production speed or maintain product consistency, the MIC 12-1 offers a robust, user-friendly design that ensures superior results with every can.

|

|

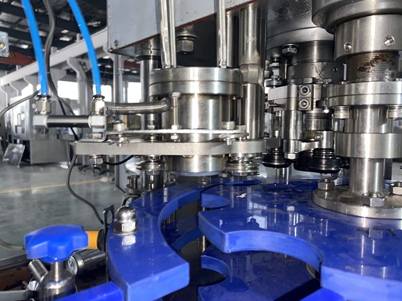

Can filling seaming machine foaming device

|

|

Can filling seaming machine liquid tank A Can Filling Seaming Machine Liquid Tank is a storage component that holds the beverage (such as beer or soda) before it is filled into cans. Positioned above the filling station, the tank ensures a steady and consistent supply of liquid to the filling machine. It is designed to maintain the correct pressure and temperature to ensure accurate fills and prevent spillage. The liquid tank typically features precise control systems to regulate liquid levels and flow rates, ensuring smooth and efficient operation of the canning process. |

|

|

|

can filling seaming machine lid feed system The can filling seaming machine lid feed system is designed to automate the process of feeding lids onto cans. It ensures precise placement, minimizing errors and increasing efficiency during the filling and sealing process, crucial for high-speed production lines. |

Key Features of the MIC 12-1 Automatic Beer Canning Machine

1、High-Speed Operation

The MIC 12-1 is equipped with state-of-the-art technology that allows it to fill up to 12 cans simultaneously, making it an essential tool for breweries aiming to scale up their production. This speed, combined with precision, ensures that your brewery can meet high demand without sacrificing quality or consistency.

2、Craft Beer Canning Capabilities

Specially designed to meet the unique requirements of craft breweries, the MIC 12-1 excels in handling a wide range of beer styles. Whether you're packaging light lagers, robust stouts, or hoppy IPAs, this craft beer canning machine ensures that the delicate flavors and carbonation of your brews are preserved during the filling process.

3、Versatile Can Sizes

The MIC 12-1 offers flexibility in packaging various can sizes, accommodating both small-scale craft beer packaging and large-scale commercial runs. This flexibility ensures that your brewery can easily adapt to customer demands and trends in the beverage market, making it an ideal choice for a wide range of products.

4、Efficient Beer Can Filler Machine Design

The MIC 12-1 is engineered to maximize efficiency with minimal waste. Its high-precision filling system ensures that each can is filled accurately, preventing overfilling or underfilling, and reducing product waste. The integrated filling valve system adapts to the viscosity and carbonation level of your beer, providing a gentle yet effective fill every time.

5、Durability and Reliability

Constructed with high-quality materials, this beer can filler machine is built to withstand the demands of continuous operation in busy environments. Whether you’re running a small craft brewery or a large-scale production line, the MIC 12-1 provides reliable performance day in and day out, ensuring that your canning process runs smoothly.

6、Automated Control System

The MIC 12-1 comes with an intuitive, automated control system that simplifies operation and reduces the need for manual intervention. This feature not only improves efficiency but also helps reduce the risk of human error. The system offers full control over filling parameters, can sizes, and production speed, allowing for seamless adjustments to meet specific production needs.

7、Easy Maintenance and Cleaning

Maintenance is made simple with the MIC 12-1’s user-friendly design. Its modular structure allows for easy disassembly and cleaning, ensuring that the machine can be kept in optimal condition with minimal downtime. Regular maintenance routines are streamlined, allowing your brewery to focus more on production and less on upkeep.

8、Compact Design

Despite its powerful capabilities, the MIC 12-1 is designed to be space-efficient. Its compact footprint allows for easy integration into existing production lines without the need for significant space modifications. This makes it an ideal solution for breweries looking to maximize their available floor space while boosting their canning capacity.

Why Choose the MIC 12-1 Automatic Beer Canning Machine?

When it comes to packaging beer, consistency, speed, and quality are crucial. The MIC 12-1 beer canning machine is engineered to meet these demands with cutting-edge technology and a reliable design. Whether you're running a small craft brewery or a large commercial operation, the MIC 12-1 ensures that your beer is packaged with precision, preserving the flavor and carbonation of your product from the brewery to the consumer’s hand.

With its versatility, efficiency, and ease of use, the MIC 12-1 is the ultimate beer can filler machine for modern breweries. Choose MIC Machinery for all your beer canning needs and take your brewery’s production to the next level.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

More Model And Speed Click

| Model | MIC 12-1 | MIC 18-1 | MIC 18-6 | MIC 24-6 | MIC 32-8 |

| Application | Beer, Carbonated Beverage, Gas Drinks, Cold Coffee, Sparking Water, Cider, Soda Water, Herbal Tea, Non-Carbonated Drinks And So On | ||||

| Packing Type | Aluminum Cans, Metal Cans, Tin Cans, Pet Cans Etc | ||||

| Speed | 1000-2000CPH | 1000-2500CPH | 3000-6000CPH | 4000-8000CPH | 6000-10000CPH |

| Filling Arrange | 180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) | ||||

| Power | 1.1kw | 1.5kw | 2.5kw | 3.5kw | 4.2kw |

| Size | 1.8*1.3*1.95 (M) | 1.9*1.3*1.95(M) | 2.3*1.4*1.9(M) | 2.58*1.7*1.8(M) | 2.8*1.7*1.95(M) |

| Weight | 1800KG | 2100KG | 2500KG | 3000KG | 3800(KG) |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |