MIC 8 Head Semi Automatic Beer Bottling Line (200-800BPH)

MIC 8 Head Semi-Automatic Beer Bottling Line

At Jiangsu Mic Machinery, we specialize in creating high-quality, efficient machines designed to streamline production in the beverage industry. The MIC 8 Head Semi-Automatic Beer Bottling Line is an advanced system that caters to small to medium-sized breweries, offering precision and speed in the bottling process. This semi-automatic beer bottling line is ideal for breweries that require flexibility and efficiency while maintaining high standards of quality and consistency in every bottle.

Our company has built a solid reputation for designing robust and reliable machinery that optimizes production workflows, and the MIC 8 Head system is no exception. This beer line features a versatile, easy-to-use design, making it an excellent choice for breweries seeking to increase their bottling capabilities without the complexity of a fully automated system.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

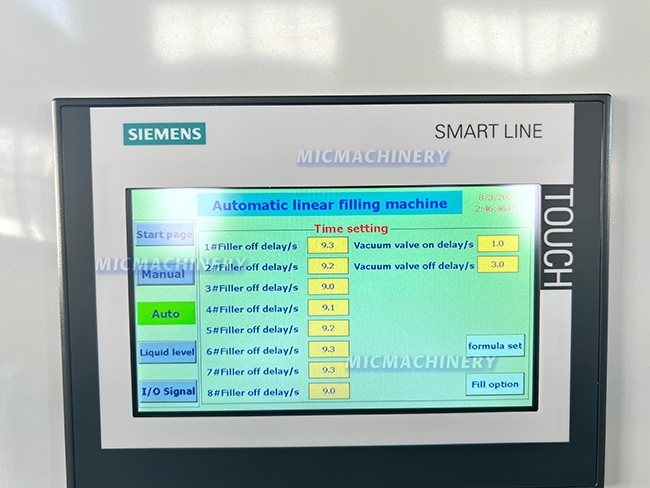

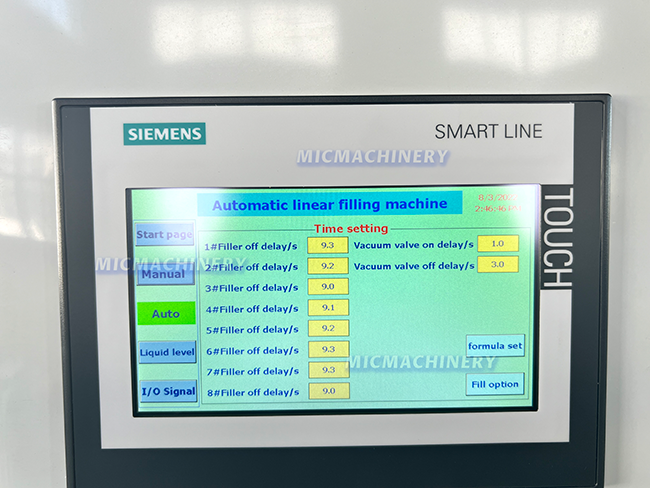

Control Panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Equipment Introduction

The MIC 8 Head Semi-Automatic Beer Bottling Line is equipped with eight filling heads, allowing for a faster bottling process with enhanced accuracy. This system can handle various bottle sizes, making it perfect for breweries with different packaging requirements. It also integrates a highly efficient capping system that ensures each bottle is sealed securely to preserve the quality and freshness of the beer. The machine is capable of filling up to 8,000 bottles per hour, depending on the beer's viscosity and the bottle size, making it an ideal solution for craft breweries looking to scale their operations while keeping costs low.

This craft beer bottling line is designed to be easy to operate, with simple controls and a user-friendly interface that allows operators to quickly adjust settings to match production needs. The semi-automatic nature of the system provides flexibility, allowing for manual intervention when necessary, while still delivering high-speed operation for optimal efficiency.

Advantages

1.High-Speed Operation

The MIC 8 Head system can bottle a large volume of beer per hour, reducing downtime and maximizing brewery output.

2.Flexible and Adaptable

This beer bottling line is capable of handling different bottle sizes and types, offering flexibility for breweries that produce a variety of craft beers.

3.Precise Filling and Sealing

The system features advanced filling technology, ensuring each bottle is filled accurately and sealed tightly to prevent leaks and preserve carbonation.

4.Semi-Automatic Operation

With a combination of automated and manual processes, this line allows operators to have more control over the production, making it ideal for smaller-scale craft breweries or breweries transitioning to larger volumes.

5.Cost-Effective

The craft beer bottling line offers breweries an affordable solution that doesn't compromise on quality. It’s an excellent investment for breweries that need to improve their bottling process without the high cost of fully automated systems.

6.Durable and Reliable

Built with high-quality materials, this system is designed to withstand the rigorous demands of a brewery environment, ensuring long-term reliability and minimal maintenance.

7.User-Friendly Interface

The intuitive controls make it easy for operators to adjust settings and perform routine maintenance tasks, ensuring smooth and efficient operation.

The MIC 8 Head Semi-Automatic Beer Bottling Line offers an effective, efficient, and cost-effective solution for craft breweries looking to streamline their bottling process while maintaining high production standards. Whether you're looking to expand your production capacity or upgrade your existing bottling system, this machine delivers the flexibility, precision, and reliability you need for success in the craft beer industry.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

Name |

Brand |

|

|

1 |

Push Button |

Schneider France |

|

2 |

Electromagnetic Contactor |

Schneider France |

|

3 |

Relays |

Omron Japan |

|

4 |

Frequency Converter |

Siemens |

|

5 |

Air Cylinder |

AirTAC Taiwan |

|

6 |

Electromagnetic Valve |

AirTAC Taiwan |

|

7 |

PLC Control System |

Siemens |

|

8 |

Touch Screen |

Siemens |

|

9 |

Photoelectric Switch |

Autonics |

|

10 |

Proximity Switch |

Autonics |

|

11 |

Reducer |

Zhejiang Duoli China |

|

12 |

Sealing Motor |

Zhejiang Duoli China |

|

13 |

Barometer |

AirTAC Taiwan |

|

14 |

Bearing |

Harbin China |