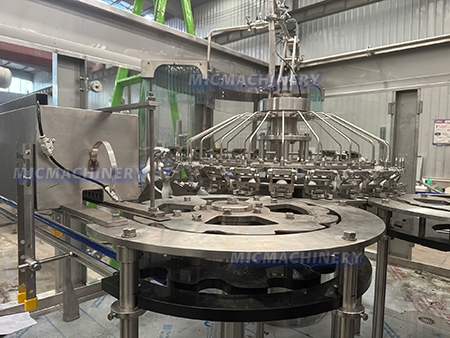

MIC 24-24-8 Water Filling Machine

Introduction to the MIC 24-24-8 Water Filling Machine

Jiangsu Mic Machinery is proud to present the MIC 24-24-8 water filling machine, a state-of-the-art solution designed for efficient, high-volume water bottling. This advanced system is engineered to meet the demands of modern production lines, offering exceptional speed, precision, and hygiene.

|

Control Panel The Control Panel with Water Filling Machine offers precise control over the filling process. With an intuitive interface, it ensures accurate volume measurement, efficient operation, and seamless automation for water bottling. |

|

Filling Head The Filling Head with Water Filling Machine is designed to ensure precise and consistent filling of water bottles. Equipped with advanced technology, it minimizes spillage and ensures accurate volume measurement for each bottle. Ideal for high-speed, automated water bottling processes, it enhances efficiency and reduces downtime. |

|

Machine is Suitable For

The MIC 24-24-8 automatic water filling machine is ideal for high-speed bottling of packaged drinking water. It is perfect for large-scale production facilities that require fast and reliable packaging solutions. Whether you are filling bottles for purified water, spring water, or mineral water, this versatile machine ensures consistent, high-quality results. Its adaptability makes it a top choice for manufacturers aiming to meet the growing demand for bottled water in various markets.

Machine Features

The MIC 24-24-8 water filling machine boasts an array of features that optimize efficiency, quality, and ease of operation:

1.High-Speed Operation

With 24 filling valves and 24 capping stations, this machine can process up to 8,000 bottles per hour, ensuring optimal throughput for large-scale production.

2.Automatic Control System

The machine is fully automated, reducing the need for manual intervention. Its advanced PLC control system allows for precise control of the filling, capping, and rinsing processes.

3.Hygienic and Safe

Designed with hygiene in mind, this automatic water filling machine meets strict sanitation standards. The parts in contact with water are made of stainless steel, ensuring durability and preventing contamination.

4.Energy-Efficien

The system incorporates energy-saving components that reduce power consumption while maintaining high performance.

5.Flexible Bottle Types

It is compatible with various bottle sizes and shapes, providing versatility for different packaging requirements.

Machine Introduction

The MIC 24-24-8 packaged drinking water machine is designed for companies looking to streamline their bottling operations without compromising on quality. This automatic water filling machine integrates rinsing, filling, and capping functions into a single, highly efficient system. With its user-friendly interface, operators can easily monitor and adjust settings, making it a reliable choice for any water bottling plant. Whether you are expanding your production capacity or starting a new line, the MIC 24-24-8 offers unmatched performance and reliability in the water filling industry.

At Jiangsu Mic Machinery, we pride ourselves on delivering cutting-edge technology to meet the unique needs of our clients. The MIC 24-24-8 is a perfect example of our commitment to excellence and innovation in packaging machinery.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |