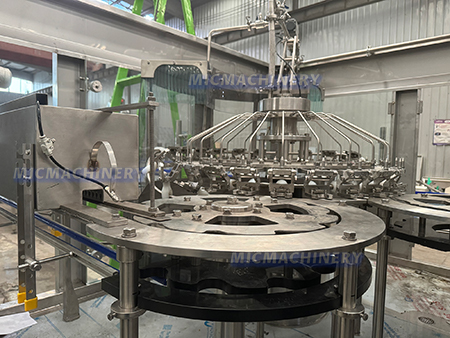

MIC 24-24-8 Bottle Water Machine

MIC 24-24-8 Bottle Water Machine

Mic Machinery is a professional manufacturer specializing in high-performance beverage packaging equipment. With a strong R&D background and global service capabilities, we deliver reliable solutions to meet the growing demand in the bottled water industry. Our MIC 24-24-8 Bottle Water Machine combines efficiency, hygiene, and automation, making it a preferred choice for businesses seeking a dependable automatic bottle water machine.

|

Control Panel The Control Panel with Water Filling Machine offers precise control over the filling process. With an intuitive interface, it ensures accurate volume measurement, efficient operation, and seamless automation for water bottling. |

|

Filling Head The Filling Head with Water Filling Machine is designed to ensure precise and consistent filling of water bottles. Equipped with advanced technology, it minimizes spillage and ensures accurate volume measurement for each bottle. Ideal for high-speed, automated water bottling processes, it enhances efficiency and reduces downtime. |

|

Working Principle

The bottle water machine integrates rinsing, filling, and capping into a streamlined rotary system:

▪ Step 1 – Bottle Rinsing (24 Heads): Empty bottles are clamped and rinsed with sterile water inside and out to eliminate dust and impurities.

▪ Step 2 – Bottle Filling (24 Heads): After rinsing, bottles are automatically filled with water using gravity filling for precise volume control.

▪ Step 3 – Capping (8 Heads): Bottles move to the capping station where screw caps are automatically applied and sealed tightly.

▪ Step 4 – Discharge: Finished bottles exit the machine, ready for labeling and packing.

Features and Advantages

▪ Compact & Integrated Design: Combines three essential processes into one unit, saving floor space.

▪ High Output Efficiency: Capable of processing up to 6,000 bottles per hour, ideal for mid-scale production.

▪ Touchscreen Operation: Simple PLC-based control panel with fault alarms and production monitoring.

▪ Food-Grade Materials: All contact parts are made from stainless steel, ensuring sanitary operation.

▪ Flexible Bottle Compatibility: This automatic bottle water machine supports various bottle sizes with quick changeover features.

Applications

The MIC 24-24-8 bottle water machine is suitable for producing bottled purified water, mineral water, and spring water. It is widely used in water bottling plants, contract packaging companies, and startup bottling lines. As a water bottling machine for sale, it offers both reliability and excellent return on investment for businesses in need of scalable water production solutions.

Conclusion

Combining precision, durability, and automation, the MIC 24-24-8 Bottle Water Machine is a smart choice for efficient bottled water production. Whether you're upgrading an existing line or launching a new facility, this automatic bottle water machine will meet your performance needs. Choose Mic Machinery for dependable packaging solutions tailored to your success.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |