MIC 18-18-6 Water Bottling Equipment (5000-8000BPH)

MIC 18-18-6 Water Bottling Equipment (5000-8000BPH)

Company Introduction

Jiangsu Mic Machinery is a leading innovator in the design and manufacture of advanced bottling equipment. With a commitment to excellence and continuous innovation, we have established ourselves as a trusted water bottling equipment manufacturer, providing high-quality, high-efficiency machines to meet the growing demands of the beverage industry. Our machines are built to ensure maximum efficiency and reliability, helping businesses scale their production operations seamlessly. As a professional plastic water bottle machine and water bottling machine supplier, we are proud to offer equipment that is designed for both small-scale and high-speed large-scale bottling processes.

At Jiangsu Mic Machinery, we understand the importance of high-quality production, and our machines reflect this commitment to excellence. Our water bottling equipment is trusted by companies worldwide for its durability, ease of operation, and cost-effectiveness.

|

|

Bottle Washing Machine The Bottle Washing Machine effectively cleans bottles before filling, removing dirt, debris, and residues. It ensures hygienic conditions for bottling operations, improving product quality and operational efficiency in high-speed production lines. |

|

Cap Screwing Machine The Cap Screwing Machine efficiently places and tightens caps onto bottles during the bottling process. It ensures secure sealing, preventing leaks and contamination, and enhances productivity in high-speed packaging operations. |

|

|

|

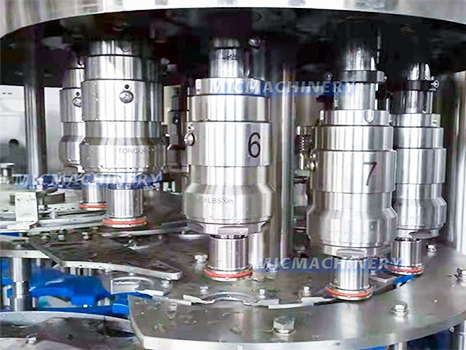

Filling System The Filling System is designed to accurately fill bottles with liquids, ensuring precise volume control and minimizing waste. It supports high-speed operations, improving efficiency and consistency in bottling lines. |

Features

The MIC 18-18-6 water bottling equipment is specifically designed for large-scale, high-speed water bottling operations. With a capacity ranging from 5000 to 8000 bottles per hour (BPH), this machine offers exceptional performance for high-volume production. The equipment integrates several key features to ensure consistent and precise bottling, including:

Automatic Rinsing System: This system ensures thorough cleaning of each bottle before the filling process, eliminating contamination risks and maintaining product quality.

High-Precision Filling Mechanism: The plastic water bottle machine is equipped with an advanced filling system that guarantees precise fill levels and minimizes wastage, ensuring uniformity across production runs.

Fast Capping Mechanism: After the bottles are filled, an automatic capping system is employed, ensuring secure sealing for each bottle and preventing leaks during transport.

User-Friendly Interface: The machine is controlled through an intuitive touch screen interface, making it easy for operators to monitor and adjust the production process as needed.

Flexible Design: The water bottling machine can be adjusted to accommodate different bottle sizes and shapes, offering flexibility to businesses with varying packaging needs.

Advantages

The MIC 18-18-6 water bottling equipment offers several key advantages that make it an ideal choice for businesses in the water bottling industry:

1、High-Speed Performance

With an impressive output of 5000-8000 bottles per hour, this equipment significantly increases production efficiency, making it a perfect choice for businesses looking to scale their operations.

2、Precision and Consistency

The machine’s advanced filling system ensures consistent filling volumes across all bottles, maintaining the quality and uniformity of the product while minimizing waste.

3、Durable and Reliable

Built with high-quality materials and components, this plastic water bottle machine is designed for long-term use with minimal downtime, making it a sound investment for high-volume production lines.

4、Reduced Labor Costs

The automation of the rinsing, filling, and capping processes reduces the need for manual intervention, resulting in lower labor costs and greater overall efficiency.

5、Cost-Effective Operation

The high-speed capabilities and low maintenance requirements of the water bottling machine make it a cost-effective solution for large-scale bottling operations, providing significant savings over time.

In conclusion, the MIC 18-18-6 water bottling equipment offers a combination of high-speed performance, precision engineering, and cost-effectiveness that makes it an excellent choice for companies looking to optimize their water bottling operations. With its advanced features, flexibility, and durability, it is the ideal solution for businesses aiming to increase production efficiency and ensure high-quality standards in their bottled water products.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |