MIC 18-18-6 Plastic Water Bottle Packing Machine (5000-8000BPH)

MIC 18-18-6 Plastic Water Bottle Packing Machine (5000-8000BPH)

Company Introduction

Jiangsu Mic Machinery is a leading provider of innovative filling and packaging solutions for the beverage industry. With years of experience in manufacturing high-quality equipment, we specialize in providing cutting-edge technologies such as the MIC 18-18-6 plastic water bottle packing machine. Our machines are designed for superior efficiency, high capacity, and exceptional reliability, making us a trusted partner for beverage manufacturers around the world. With a commitment to excellence and customer satisfaction, Jiangsu Mic Machinery is dedicated to enhancing your production line and helping you meet market demands efficiently.

|

|

Bottle Washing Machine The Bottle Washing Machine effectively cleans bottles before filling, removing dirt, debris, and residues. It ensures hygienic conditions for bottling operations, improving product quality and operational efficiency in high-speed production lines. |

|

Cap Screwing Machine The Cap Screwing Machine efficiently places and tightens caps onto bottles during the bottling process. It ensures secure sealing, preventing leaks and contamination, and enhances productivity in high-speed packaging operations. |

|

|

|

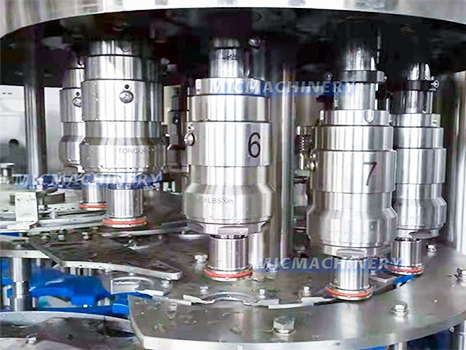

Filling System The Filling System is designed to accurately fill bottles with liquids, ensuring precise volume control and minimizing waste. It supports high-speed operations, improving efficiency and consistency in bottling lines. |

Features

The MIC 18-18-6 water packaging bottle machine is engineered to provide high-speed, automated filling, capping, and packaging for plastic water bottles. This advanced system is built with a range of features to ensure optimal performance in high-demand environments.

High-Speed Operation: With a capacity of 5000-8000 bottles per hour (BPH), the drinking water bottle packing machine is designed to meet the needs of large-scale production lines.

Automatic Control System: Featuring a fully automated process, the machine minimizes human intervention and ensures smooth operation from start to finish.

Flexible Bottle Handling: Capable of accommodating various bottle sizes, the machine provides versatility for different packaging requirements.

Precise Filling Technology: The plastic water bottle packing machine ensures precise filling with minimal spillage, using pressure-controlled filling systems that maintain uniform bottle levels.

Reliable Capping System: Bottles are securely capped after filling, ensuring leak-proof packaging that preserves product integrity.

Easy Maintenance: Designed for easy cleaning and maintenance, the machine’s components are simple to disassemble and reassemble, reducing downtime and maintenance costs.

Advantages

The MIC 18-18-6 water packaging bottle machine offers numerous advantages, making it the perfect choice for large-scale, high-efficiency bottling operations.

1、Enhanced Productivity

With the ability to process 5000-8000 bottles per hour, this drinking water bottle packing machine significantly boosts production capacity, helping businesses meet growing consumer demand.

2、Cost-Effective

Automation reduces labor costs, while the machine’s high efficiency lowers energy consumption, offering a strong return on investment.

3、Consistent Quality

The advanced filling and capping mechanisms ensure consistent product quality across every bottle, reducing the risk of defects and maintaining high-quality standards.

4、Robust and Durable

Built with high-quality, durable materials, the machine is designed to withstand long-term operation, providing reliable performance for years.

5、Versatility

Whether you’re packaging still water, mineral water, or flavored water, the plastic water bottle packing machine offers the flexibility to handle a variety of water products.

6、Hygienic Design

Designed with sanitation in mind, the machine is easy to clean, ensuring that your production line meets all hygiene standards and regulatory requirements.

The MIC 18-18-6 plastic water bottle packing machine is an ideal solution for businesses looking to optimize their bottling operations, boost efficiency, and enhance product quality. With its advanced technology and high-performance features, it stands out as a reliable, cost-effective option for modern water bottling plants.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |