MIC 18-18-1 Glass Bottling Line (800-1500 BPH)

MIC 18-18-1 Glass Bottling Line

Company Introduction

Jiangsu Mic Machinery is a global leader in the design and manufacture of advanced filling and packaging solutions. With years of expertise in the industry, we specialize in offering high-performance machinery that meets international standards. Our commitment to precision, quality, and customer satisfaction has made us a trusted partner for beverage manufacturers worldwide. At Jiangsu Mic Machinery, we are dedicated to providing innovative solutions, like the MIC 18-18-1 Glass Bottling Line, which helps our clients optimize their production processes while maintaining top-tier product quality.

|

|

Beer bottling production line |

|

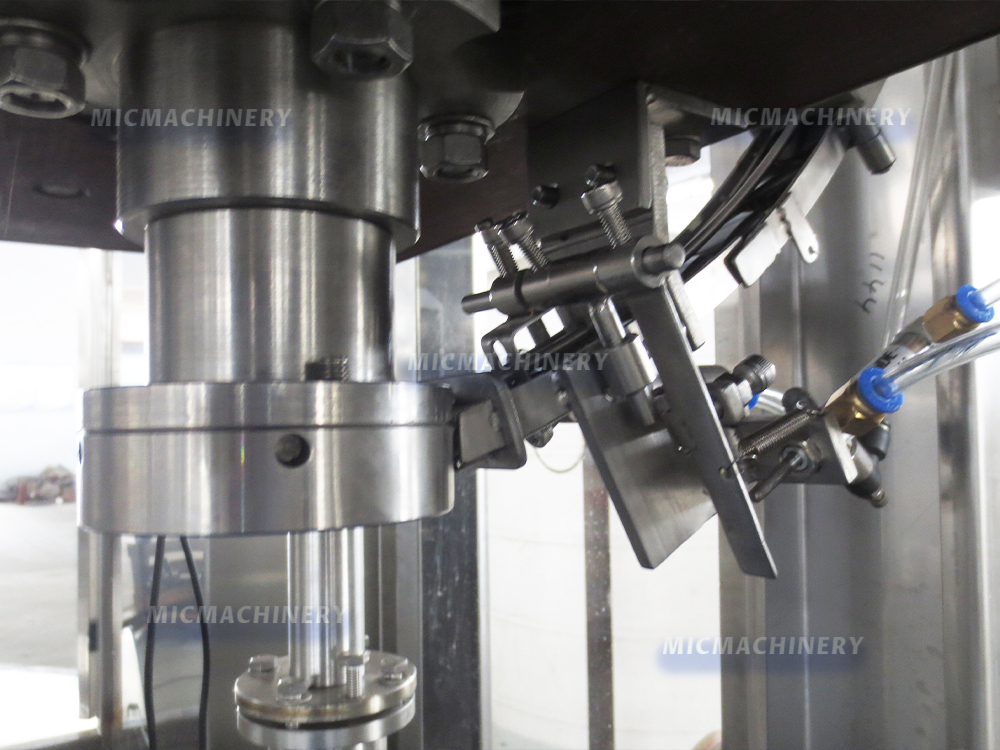

Capping Part The capping part of a bottling line securely seals bottles after filling, preventing contamination and ensuring product freshness. Equipped with advanced technology, it applies caps consistently at high speeds, offering precision and reliability for various bottle types and cap formats in production. |

|

|

|

Filling part The filling part of a bottling line is responsible for accurately dispensing beverages into bottles. Using advanced filling valves and precision control systems, it ensures consistent fill levels and minimizes spillage, allowing for high-speed, efficient operations and maintaining product quality across different bottle sizes. |

Working Principle

The MIC 18-18-1 Glass Bottling Line is a highly automated system designed to streamline the process of filling, capping, and labeling glass bottles for beverage production. The process begins with the automatic loading of glass bottles onto the conveyor. These bottles are then cleaned and sterilized to ensure they are free from contaminants, providing a hygienic environment for filling.

Once the bottles are prepared, the glass bottle filling line begins the filling process, accurately dispensing the required amount of liquid into each bottle. The system uses precise technology to avoid overfilling, ensuring each bottle is filled to the correct volume while minimizing waste. After the bottles are filled, they move to the capping station, where caps are securely applied to ensure product integrity during storage and transport.

Finally, the bottles are labeled with high-quality labels using the line’s efficient labeling system. This ensures that each bottle is properly branded before being sent for distribution or storage. The entire process is automated, ensuring minimal manual intervention and reducing the chance for human error.

Function

The MIC 18-18-1 Glass Bottling Line offers a comprehensive, automated solution for beverage manufacturers. It integrates the essential stages of production—filling, capping, and labeling—into one streamlined process.

This glass bottle production line is versatile, accommodating a wide variety of beverages, including carbonated drinks, juices, and still water. It is designed to handle different bottle sizes and shapes, providing flexibility for various production requirements. The system’s high-speed operation allows it to process 800-1500 bottles per hour, making it suitable for medium-scale production while maintaining high standards of product quality.

The machine is equipped with advanced control systems that allow operators to monitor and adjust the settings easily, making it adaptable to changing production needs. Additionally, the system is designed with safety and efficiency in mind, reducing the need for manual labor and minimizing the risk of human error.

Advantages

The MIC 18-18-1 Glass Bottling Line offers several advantages that make it an ideal choice for beverage manufacturers:

High-Speed Efficiency: With a production capacity of 800-1500 bottles per hour, this glass bottle filling line ensures that businesses can meet medium-scale production demands without compromising quality or efficiency.

1.Versatility

The glass bottling line can handle a wide range of beverages, including carbonated drinks, juices, and still water, making it suitable for diverse production needs. It can also accommodate different glass bottle sizes, providing flexibility for various product lines.

2.Precision Filling Technology

The system uses advanced filling technology to ensure each bottle is filled to the correct level, minimizing waste and improving operational efficiency. This precise control leads to significant cost savings.

3.Durability and Reliability

The glass bottle production line is built with high-quality materials, ensuring long-term durability and continuous, reliable performance. The robust design reduces downtime and increases the overall lifespan of the system.

4.Energy Efficiency

The system is designed to be energy-efficient, helping to reduce operational costs while maintaining high performance. This makes the line not only cost-effective but also environmentally friendly.

5.Ease of Maintenance

The design of the MIC 18-18-1 Glass Bottling Line makes it easy to clean and maintain. This reduces downtime, ensures high uptime, and keeps the production process running smoothly with minimal intervention.

In conclusion, the MIC 18-18-1 Glass Bottling Line offers a reliable, efficient, and versatile solution for beverage manufacturers. With its high-speed performance, precision filling, and easy maintenance, it is the ideal choice for businesses looking to streamline their glass bottle packaging process while maintaining the highest quality standards.

|

1 |

Filling Nozzle |

18 heads |

|

2 |

Water Rinse Nozzle |

18 heads |

|

3 |

Capping Head |

1 heads |

|

4 |

Filling Volume |

330ML |

|

5 |

Filling Speed |

800-1500BPH |

|

6 |

Air Pressure |

0.6Mpa |

|

7 |

Air Consume |

0.15m3/min |

|

8 |

Washing Water Pressure |

0.2MPa |

|

9 |

Washing Water Consume |

About 1T-2T/hour |

|

10 |

Main Motor Power |

0.75KW |

|

11 |

Total Power |

2.5KW |

|

12 |

Size |

2600mm*1550mm*2200mm (length* width* height) |

|

13 |

Total Weight |

2500KG |

|

14 |

Voltage |

220/380V 50-60Hz (Can be customized) |

|

15 |

Control |

PLC+Touch Screen |

|

16 |

Material |

SUS 304 |

|

17 |

Filling Pressure |

0.2~0.5Mpa |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |