MIC 18-18-1 Glass Bottle Packing Machine (800-1500 BPH)

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer and supplier of advanced filling and packaging machinery. With a focus on delivering high-quality and efficient solutions, we specialize in glass filling machines, glass bottle packing machines, and other cutting-edge equipment for industries like beverages, food. Our commitment to innovation and customer satisfaction has earned us a reputation for reliability and excellence in the global marketplace.

|

|

Beer bottling production line |

|

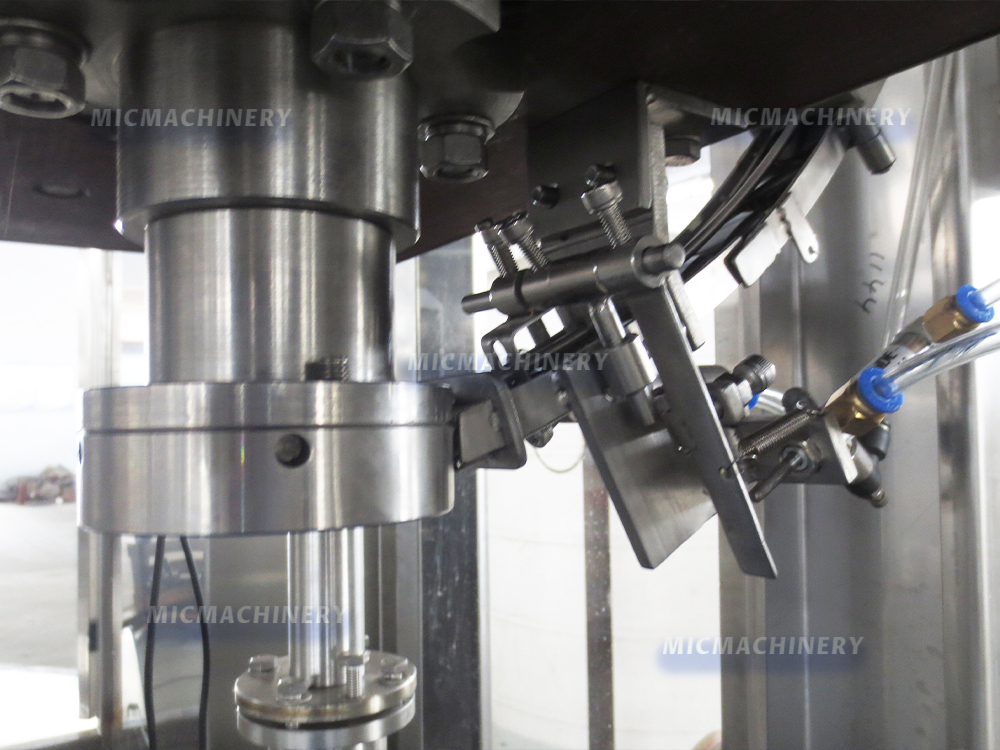

Capping Part The capping part of a bottling line securely seals bottles after filling, preventing contamination and ensuring product freshness. Equipped with advanced technology, it applies caps consistently at high speeds, offering precision and reliability for various bottle types and cap formats in production. |

|

|

|

Filling part The filling part of a bottling line is responsible for accurately dispensing beverages into bottles. Using advanced filling valves and precision control systems, it ensures consistent fill levels and minimizes spillage, allowing for high-speed, efficient operations and maintaining product quality across different bottle sizes. |

Working Principle of Glass Bottling Machine

The MIC 18-18-1 glass bottle packing machine is a high-speed and highly efficient system designed for the precise filling and packaging of beverages in glass bottles. The machine operates using an integrated combination of mechanical, pneumatic, and electrical systems to ensure optimal performance at speeds up to 15,000 bottles per hour.

At the start of the process, empty glass bottles are fed onto the conveyor system, where they are automatically positioned by the machine's gripper system. Once aligned, the bottles are transferred to the filling station. The glass bottle filling machine for sale utilizes 18 filling heads that dispense beverages at a controlled rate, ensuring uniform fill levels and reducing overfill risks. This design allows the system to handle a wide variety of beverage types, from carbonated drinks to non-carbonated liquids.

After filling, the bottles are moved to the capping station, where they are securely sealed. The process is highly automated, requiring minimal manual intervention, and ensures fast, precise, and hygienic packaging.

Function

The glass bottle packing machine integrates multiple functions to create a seamless and efficient production line. These include automatic bottle feeding, precise filling, capping, and labeling. By automating each stage of the process, this machine eliminates human error, reduces labor costs, and increases overall productivity.

In addition to its core functions, the glass filling machine is equipped with advanced control systems, which allow operators to fine-tune filling parameters such as speed and fill volume. This flexibility ensures that the machine can accommodate different bottle sizes and packaging requirements, making it ideal for a wide range of beverage applications.

Moreover, the glass bottle packing machine is designed to be highly versatile, capable of handling both glass and PET bottles with ease, offering more options for businesses looking to expand or diversify their production capabilities.

Advantages of MIC 18-18-1 Glass Bottle Packing Machine

The MIC 18-18-1 glass bottle packing machine offers numerous advantages that enhance the efficiency, quality, and scalability of any bottling operation:

1、High-Speed Operation

With a capacity of 15,000 bottles per hour, this glass filling machine is ideal for large-scale production environments, enabling companies to meet high demand while maintaining consistent product quality.

2、Precision and Accuracy

Equipped with 18 filling heads, the machine ensures accurate fill levels, minimizing wastage and ensuring each bottle receives the correct amount of liquid. This precision is critical in maintaining product consistency and reducing errors in the production process.

3、Reduced Labor Costs

Fully automated, the glass bottle packing machine requires minimal human intervention, lowering labor costs and enhancing safety. Operators can monitor the process from the user-friendly control panel, making adjustments as needed.

4、Energy Efficiency

Designed with energy-saving features, the glass bottle filling machine for sale helps businesses reduce operational costs. Its efficient filling and capping mechanisms optimize throughput without consuming excessive amounts of power.

5、Versatility

The machine can handle a variety of glass bottle sizes, making it adaptable to different production requirements. Whether you need to fill small bottles or larger containers, the machine can be quickly adjusted to accommodate the change.

6、Durability and Reliability

Constructed with high-quality stainless steel, the glass bottle packing machine is built to withstand the rigors of continuous, high-speed operations. This robust design ensures long-term reliability and reduced maintenance needs.

7、Hygienic Design

The machine’s hygienic construction minimizes the risk of contamination during the filling and sealing processes, ensuring that every bottle is packed safely and in accordance with industry standards.

8、Customizable Options

The MIC 18-18-1 glass bottle packing machine offers customizable settings for different types of beverages, including carbonated and non-carbonated drinks, as well as alcoholic and non-alcoholic products, enhancing its versatility for diverse applications.

By incorporating advanced technology, high-quality materials, and user-friendly features, the MIC 18-18-1 glass bottle packing machine from Jiangsu Mic Machinery provides a reliable and efficient solution for large-scale glass bottle packaging needs.

|

1 |

Filling Nozzle |

18 heads |

|

2 |

Water Rinse Nozzle |

18 heads |

|

3 |

Capping Head |

1 heads |

|

4 |

Filling Volume |

330ML |

|

5 |

Filling Speed |

800-1500BPH |

|

6 |

Air Pressure |

0.6Mpa |

|

7 |

Air Consume |

0.15m3/min |

|

8 |

Washing Water Pressure |

0.2MPa |

|

9 |

Washing Water Consume |

About 1T-2T/hour |

|

10 |

Main Motor Power |

0.75KW |

|

11 |

Total Power |

2.5KW |

|

12 |

Size |

2600mm*1550mm*2200mm (length* width* height) |

|

13 |

Total Weight |

2500KG |

|

14 |

Voltage |

220/380V 50-60Hz (Can be customized) |

|

15 |

Control |

PLC+Touch Screen |

|

16 |

Material |

SUS 304 |

|

17 |

Filling Pressure |

0.2~0.5Mpa |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |