MIC 18-1 Beverage Filling Production Line (1500-2500CPH)

MIC 18-1 Beverage Filling Production Line

Company Introduction

Jiangsu Mic Machinery is a leading provider of high-quality filling and packaging solutions for the beverage industry. With years of expertise and innovation, we design, manufacture, and supply efficient and reliable machinery that meets the evolving needs of beverage producers worldwide. Our commitment to quality and customer satisfaction has earned us a trusted reputation across multiple industries. The MIC 18-1 Beverage Filling Production Line is an excellent example of our dedication to delivering superior technology, efficiency, and value. This line is designed to handle a variety of beverage types, from water and juices to carbonated drinks, offering a robust solution for large-scale production.

|

|

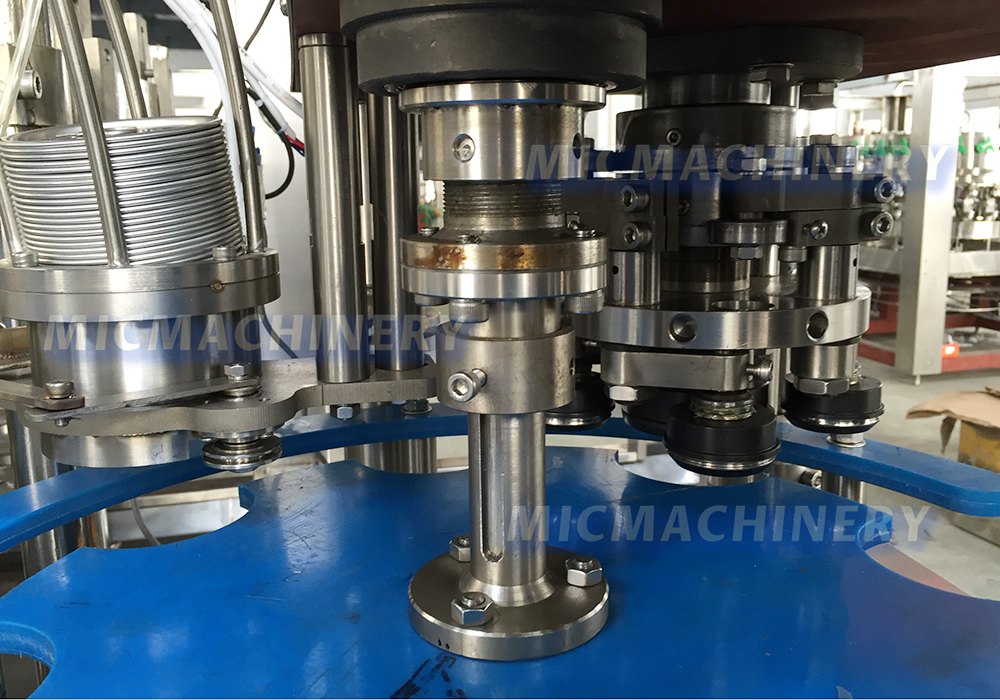

Can filling seaming machine liquid tank The liquid tank in a can filling seaming machine is essential for holding and dispensing liquid into cans with precision. Made from durable stainless steel, it ensures long-lasting performance and easy cleaning. Key features include precise flow control to prevent overflows and foam, pressure regulation to maintain optimal levels for carbonated drinks, and a hygienic design for easy cleaning, often equipped with CIP systems. Level sensors monitor liquid levels to ensure consistent filling, while temperature control maintains the ideal liquid temperature for beverages like beer. The liquid tank ensures efficient, high-quality, and hygienic filling in beverage canning operations. |

|

Can filling seaming machine foaming device

|

|

|

|

Can filling seaming machine lid feed system The lid feed system in a can filling seaming machine is responsible for automatically supplying lids to the cans during the sealing process. It ensures a smooth and continuous flow of lids, preventing delays and maintaining production efficiency. The system typically uses a conveyor or vibratory feeder to align and position lids correctly before they are placed on the filled cans. This automated process reduces the risk of contamination, improves the consistency of the seal, and speeds up the overall canning operation. The lid feed system is essential for ensuring that each can is securely sealed, maintaining product quality and preventing leakage.

|

Working Principle

The MIC 18-1 Beverage Filling Production Line operates through an automated system that streamlines the filling, capping, and labeling processes. The production begins with the arrival of empty bottles, which are cleaned and sanitized through a series of automated washing stations. After being properly sterilized, the bottles are conveyed to the filling station, where precise amounts of beverage are dispensed using advanced volumetric filling technology. This ensures that each bottle receives the exact required amount of liquid, reducing wastage and improving consistency.

Once filled, the bottles are automatically capped, creating a secure seal to prevent leakage and maintain product integrity. The final step is labeling, where the bottles are marked with clear and accurate labels that include branding, ingredient information, and other necessary details. The beverage filling line integrates these stages seamlessly, creating a high-speed, fully automated process that maximizes efficiency and minimizes human intervention.

Advantages

1.High-Speed Efficiency: The MIC 18-1 Beverage Filling Production Line is designed to operate at high speeds, ensuring that production can keep pace with demand. Its advanced automation significantly reduces downtime and increases output, making it an ideal solution for large-scale beverage production facilities.

2.Precision Filling: The line utilizes cutting-edge volumetric filling technology, which guarantees accurate and consistent filling levels across all bottles. This ensures that each beverage container is filled to the desired volume, minimizing product waste and maintaining high quality.

3.Cost-Effective Automation: With its fully automated process, this beverage production line reduces the need for manual labor, resulting in lower operational costs. Automation also improves reliability, as the system minimizes human error and ensures consistent performance.

4.Versatile and Flexible: The MIC 18-1 Beverage Filling Production Line is designed to handle a wide range of beverage products, from still water and juices to carbonated drinks. This makes it a flexible choice for manufacturers producing different types of beverages, with easy adaptation to different bottle sizes and shapes.

5.Low Maintenance and Durability: Built with high-quality components and advanced technology, this line is designed for durability and minimal maintenance. It is engineered to withstand the rigors of continuous production, ensuring longevity and reliable operation.

6.User-Friendly Control System: The line features an intuitive control panel that allows operators to easily monitor and adjust settings, ensuring smooth and efficient operation. The user-friendly interface reduces the need for extensive training and ensures that your team can operate the machine with ease.

7.Scalability: The system is scalable to accommodate growing production needs. Whether you are looking to expand your current operations or invest in future upgrades, the beverage filling line can be adapted to meet evolving production demands.

At Jiangsu Mic Machinery, we strive to offer innovative and reliable solutions that enhance beverage production processes. The MIC 18-1 Beverage Filling Production Line is a testament to our commitment to providing state-of-the-art equipment that ensures high productivity, excellent product quality, and operational efficiency.

MIC 18-1 Parameters

| Power | 1.5Kw |

| Filling heads | 18piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2500CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1900*1300*1950mm |

| Weight | 2100Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |