MIC 12-12-1 Beverage Bottling Line (800-1500BPH)

MIC 12-12-1 Beverage Bottling Line

Company Introduction

At Jiangsu Mic Machinery, we specialize in providing innovative and high-quality beverage production solutions. With years of experience in designing and manufacturing automated bottling systems, we have established ourselves as a trusted leader in the industry. Our products, such as the MIC 12-12-1 Beverage Bottling Line, are designed to meet the diverse needs of beverage manufacturers around the world. We are committed to providing efficient, reliable, and cost-effective solutions that help our clients optimize their production processes. Whether you are in the soft drink, juice, or bottled water industry, our beverage filling production line is engineered to ensure high performance and consistent output.

|

|

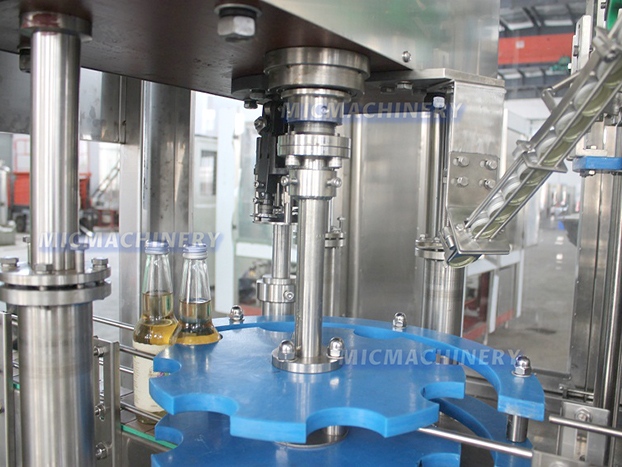

Capping Part |

|

Filling part The filling part of the MIC 12-12-1 beer bottle filler ensures precise and efficient filling with minimal wastage. It uses gravity or pressure filling methods, providing accurate fill levels for various bottle types.

|

|

|

|

Conveyor line Our conveyor line offers efficient, seamless transportation of goods in production processes. With adjustable speed and reliable performance, it streamlines workflow and boosts productivity in various industries.

|

Features

The MIC 12-12-1 Beverage Bottling Line integrates several key features that make it a top choice for beverage bottling applications:

· Advanced Automation: This line is designed to provide fully automated operation, reducing the need for manual labor. It automates the entire bottling process, including filling, capping, and labeling, which increases efficiency and reduces human error.

· High-Speed Production: The beverage production line operates at high speeds, ensuring quick filling, capping, and labeling of bottles. With an optimized throughput, this system supports large-scale production without compromising on quality.

· Precise Filling Technology: Utilizing advanced volumetric filling technology, the MIC 12-12-1 Beverage Bottling Line ensures accurate and consistent filling. This feature minimizes product wastage and ensures that each bottle is filled to the exact volume required.

· Flexible Compatibility: This bottling line is compatible with a variety of bottle sizes and shapes, providing flexibility for beverage manufacturers with diverse product ranges. The system can easily be adjusted to handle different bottle types, from small water bottles to larger juice containers.

· Efficient Capping and Labeling: The capping and labeling systems are fully integrated into the line, allowing for quick and precise application. The automated capping process ensures tight seals, while the labeling system ensures that each bottle is labeled correctly and consistently.

Advantages

Increased Production Efficiency: The MIC 12-12-1 Beverage Bottling Line offers a significant increase in production speed and efficiency. By combining the filling, capping, and labeling processes into one seamless operation, manufacturers can achieve higher throughput with minimal downtime.

1.High-Quality Output

With its precise filling and capping technology, the line ensures that each bottle is filled correctly, sealed securely, and labeled accurately. This results in high-quality finished products, ready for distribution.

2.Cost Savings

The automation provided by this beverage filling production line reduces the need for manual labor, leading to lower operational costs. Additionally, the line’s efficiency minimizes product waste, contributing to overall cost savings.

3.Low Maintenance and Durability

Built with high-quality materials, the MIC 12-12-1 Beverage Bottling Line is designed for durability and low maintenance. The robust construction ensures that the system remains reliable even under high-demand production conditions.

4.User-Friendly Operation

The intuitive control panel allows operators to easily monitor and adjust settings, ensuring smooth operation. This user-friendly design reduces the need for extensive operator training and minimizes potential errors during production.

5.Scalability

The line is scalable, meaning it can be customized to meet the growing demands of your business. Whether you are expanding production or adapting to new products, the beverage production line can be easily modified to accommodate changes.

At Jiangsu Mic Machinery, we are proud to provide solutions that enable businesses to enhance their production capabilities. The MIC 12-12-1 Beverage Bottling Line offers an ideal combination of speed, precision, and versatility, making it an essential tool for beverage manufacturers looking to optimize their production lines.

|

Model No. |

12-12-1 |

18-18-1 |

18-18-6 |

24-24-6 |

32-32-8 |

|

Rinsing Heads |

12 |

18 |

18 |

24 |

32 |

|

Filling Heads |

12 |

18 |

18 |

24 |

32 |

|

Capping Heads |

1 |

1 |

6 |

6 |

8 |

|

Filling Speed |

500-1000BPH |

800-1500BPH |

2000-4000BPH |

4000-5000BPH |

4800-7500BPH |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |